Maintenance - gas – Prochem Apex User Manual

Page 34

MAINTENANCE - GAS

APEX 86037630

4-6

WATER PUMP

Refer to the Water Pump Operation and Service

Manual for specific instructions.

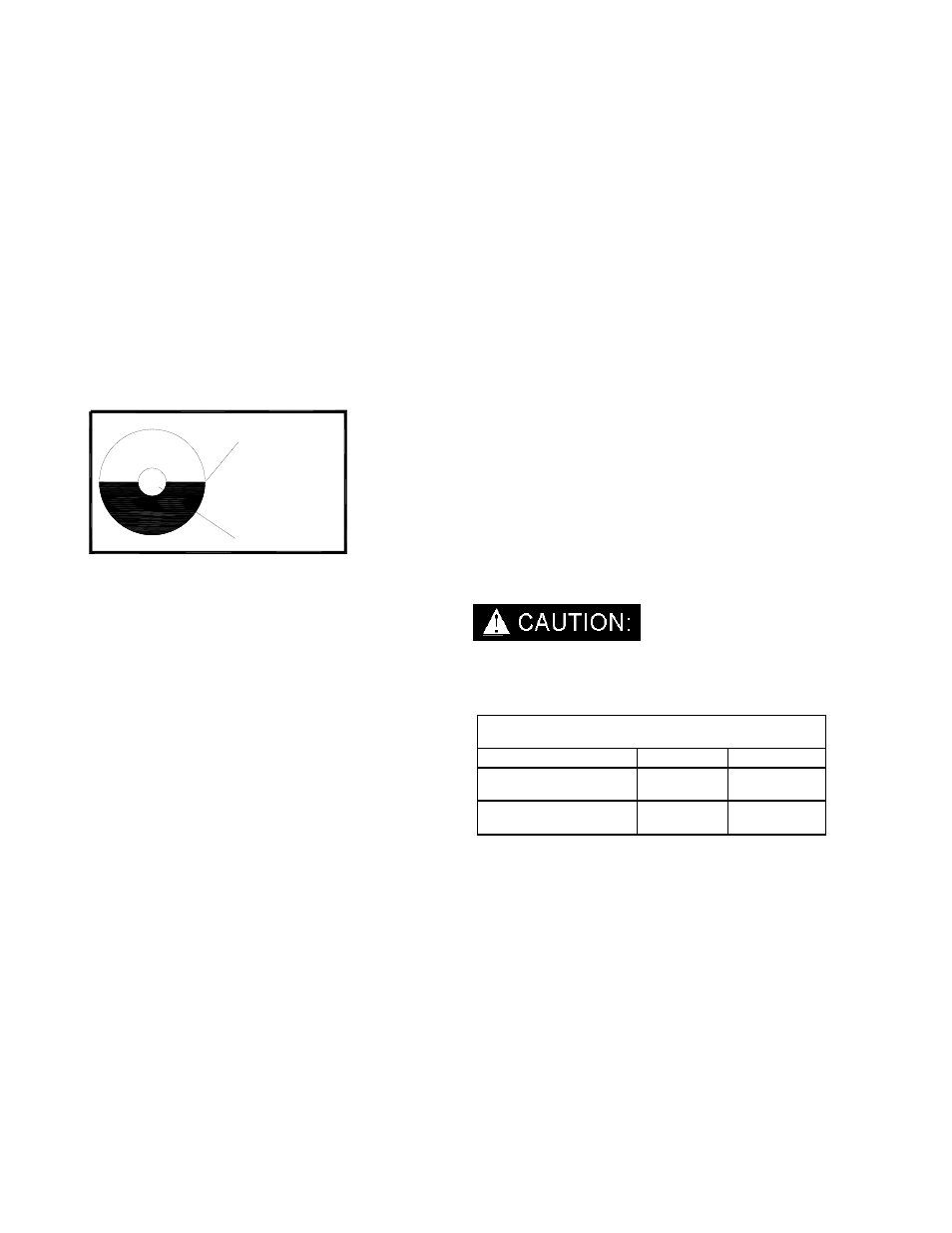

1. Check the crankcase oil level daily to assure the

proper level. Use the illustration as a guide

when checking the oil level. If the level has

dropped, check for the source of leakage and

repair.

2. Use the provided dipstick. Remove black cap

with attached dipstick. Oil level should be

between marks on the dipstick. You may also

use the site glass located on the non-shaft side

of the pump.

3. Change the crankcase oil with Interpump oil

(P/N 791106) after the first 50 hours of

operation. Drain and refill the crankcase oil

every 500 hours thereafter.

4. Other approved oil SAE 15W-40 equivalents

are: Mobil and Shell Super, Castrol CWX, and

Helix Super.

VACUUM INLET FILTER

(IN WASTE TANK)

1. The vacuum filter in the waste tank should be

removed and cleaned daily. If this is done, the

filter will last for a long period of time.

VACUUM RELIEF VALVE

While the unit is running at full RPM, block the air

flow at the vacuum inlet connection and read the

vacuum gauge. If adjustment is required, shut the

unit down and adjust the vacuum relief valve locking

nut tension. Start your unit and read the vacuum

gauge. Repeat this process until the relief valve

opens at 13" Hg.

VACUUM PUMP DRIVE BELTS

To tighten the vacuum pump belts:

1. Loosen the four screws which hold the vacuum

pump mount in place.

2. Loosen the 6 nuts at the vacuum muffler outlet

to heat exchanger box and loosen the bolt at the

back of the machine connecting the muffler

bracket to the frame.

3. Turn the adjusting bolts until the proper belt

tension is achieved (1/2” deflection in the center

of the belt, halfway between the pulleys).

4. Retighten all bolts previously loosened at the

vacuum muffler.

NOTE: When adjusting belt tension, make certain

that the engine shaft and vacuum pump shaft

remain parallel, and the belt tension is equal

throughout the belt width.

5. After adjusting, re-tighten the four screws which

hold the vacuum pump mount in position. Check

belt alignment with straight-edge.

Make certain that when you re-torque these

screws, that you use a clockwise pattern and

continue until proper torque is achieved.

Torque values

Component Inch/lbs

Foot/lbs

Rear Engine Pulley

480

40

Front Engine Pulley

300

25

6. Check for pulley groove wear, clean belts and

pulley grooves, check for worn belts, proper belt

tension, and pulley alignment after the first 25

hours and then again at 100 hours.

Check for belt ride in the groove.

OIL LEVEL

WITH UNIT

STOPPED &

ON LEVEL

GROUND

RED DOT