Dwyer GFM4 User Manual

Page 8

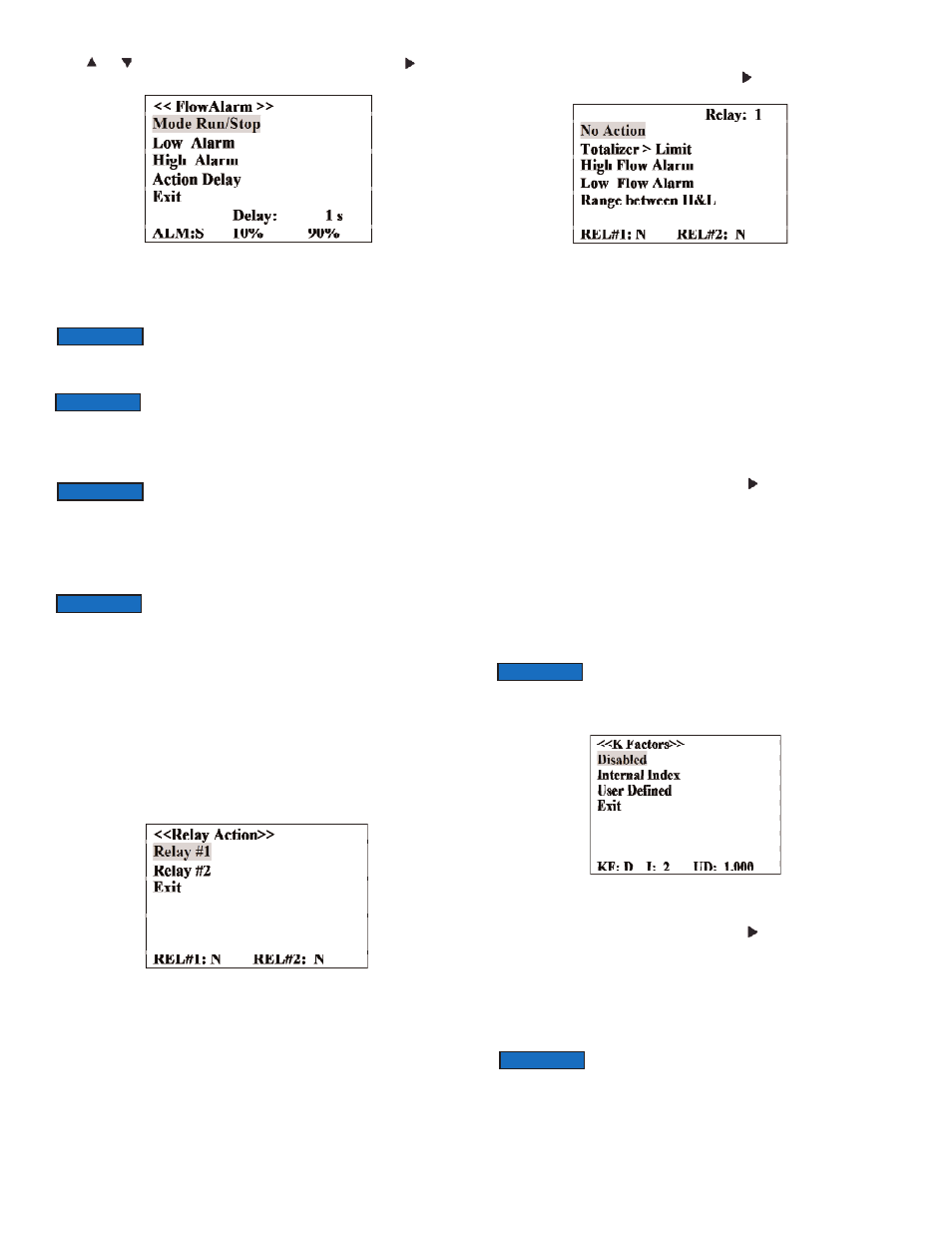

Use ( ) or ( ) button to highlight "Flow Alarm" option and press the ( ) [Enter]

button. The following screen will appear:

Figure b-14, Flow Alarm Settings

Mode Run/Stop - Allows the user to Enable/Disable Flow Alarm.

Low Alarm - The value of the monitored Flow in % FS below which is considered

an alarm condition.

High Alarm - The value of the monitored Flow in % FS above which is considered

an alarm condition.

Action Delay - The time in seconds that the Flow rate value must remain above

the high limit or below the low limit before an alarm condition is indicated. Valid

settings are in the range from 0 to 3600 seconds.

The user can enable and configure Temperature and Pressure Alarms via the

similar menu:

Main Menu " Alarm Settings " Temp. Alarms - For Temperature Alarm

Main Menu " Alarm Settings " Pres. Alarms - For Pressure Alarm

5.3.8 - Relay Assignment Settings

Two sets of dry contact relay outputs are provided to actuate user supplied

equipment. These are programmable via local keypad or digital interface, such that

the relays can be made to switch when a specified event occurs (e.g. when a low

or high flow, pressure or temperature alarm limit is exceeded, or when the totalizer

reaches a specified value).

From the Main Menu, the user would traverse the menu tree until reaching the

"Relay Action" menu. The following screen will appear:

Figure b-15, Relay Assignment Screen

The user selects a Relay by scrolling up/down the list of available Relays until the

desired Relay is highlighted and then presses the ( ) [Enter] button. The following

screen will appear:

Figure b-16, Relay #1 Action Settings

The user can configure the Relay action from 9 different options:

No Action : (N) No assignment (relay is not assigned to any events).

Totalizer > Limit : (T) Totalizer reached set limit volume.

High Flow Alarm : (H) High Flow Alarm condition.

Low Flow Alarm : (L) Low Flow Alarm condition.

Range between H&L : (R) Range between High and Low Flow Alarm condition.

High Temp. Alarm : (A) High Temperature Alarm condition.

Low Temp. Alarm : (B) Low Temperature Alarm condition.

High Pres. Alarm : (C) High Pressure Alarm condition.

Low Pres. Alarm : (D) Low Pressure Alarm condition.

Exit

The user selects an Action by scrolling up/down the list of available options until the

desired option is highlighted and then presses the ( ) [Enter] button.

5.3.9 K - Factors Settings

Conversion factors relative to Nitrogen for up to 32 gases are stored in the GFM3/4

(see APPENDIX II). In addition, provision is made for a user defined conversion

factor. Conversion factors may be applied to any of the ten gas calibrations via

keypad or digital interface commands.

The available K Factor settings are:

• Disabled - (K = 1).

• Internal Index - The index [0-31] from internal K factor table (see APPENDIX II).

• User Defined - User defined conversion factor.

From the Main Menu, the user would traverse the menu tree until reaching the "K

Factors" menu. The following screen will appear:

Figure b-17, K Factors Screen

The user selects a K factor by scrolling up/down the list of available options until

the desired option is highlighted and then presses ( ) [Enter] button. For Internal

Index and User Defined options, user will be prompted to enter desired index/value

of conversion factor.

5.3.10 - Zero Calibration

The GFM3/4 includes an auto zero function that when activated, automatically

adjusts the mass flow sensor to read zero. The initial zero adjustment for your

GFM3/4 was performed at the factory. It is not required to perform zero calibration

unless the device has zero reading offset with no flow conditions.

The value of the Low Alarm has to be less then the value of

the High Alarm.

NOTICE

If the alarm condition is detected, and the Relay is assigned to

Alarm event, then the corresponding Relay will be energized.

NOTICE

The value of the High Alarm has to be more then the value of

the Low Alarm.

NOTICE

High and Low limits for the Temperature Alarm have to be

entered in °C. High and Low limits for the Pressure Alarm have

to be entered in the currently set engineering units: PSI or kPa (absolute).

P (absolute) = P (gauge) + P (atmospheric)

NOTICE

i

The conversion factors will not be applied for % FS engineering

unit.

NOTICE

Before performing Zero Calibration, make sure the device is

powered up for at least 30 minutes and absolute no flow

condition is established.

NOTICE

Page 8