Dwyer GFM4 User Manual

Page 4

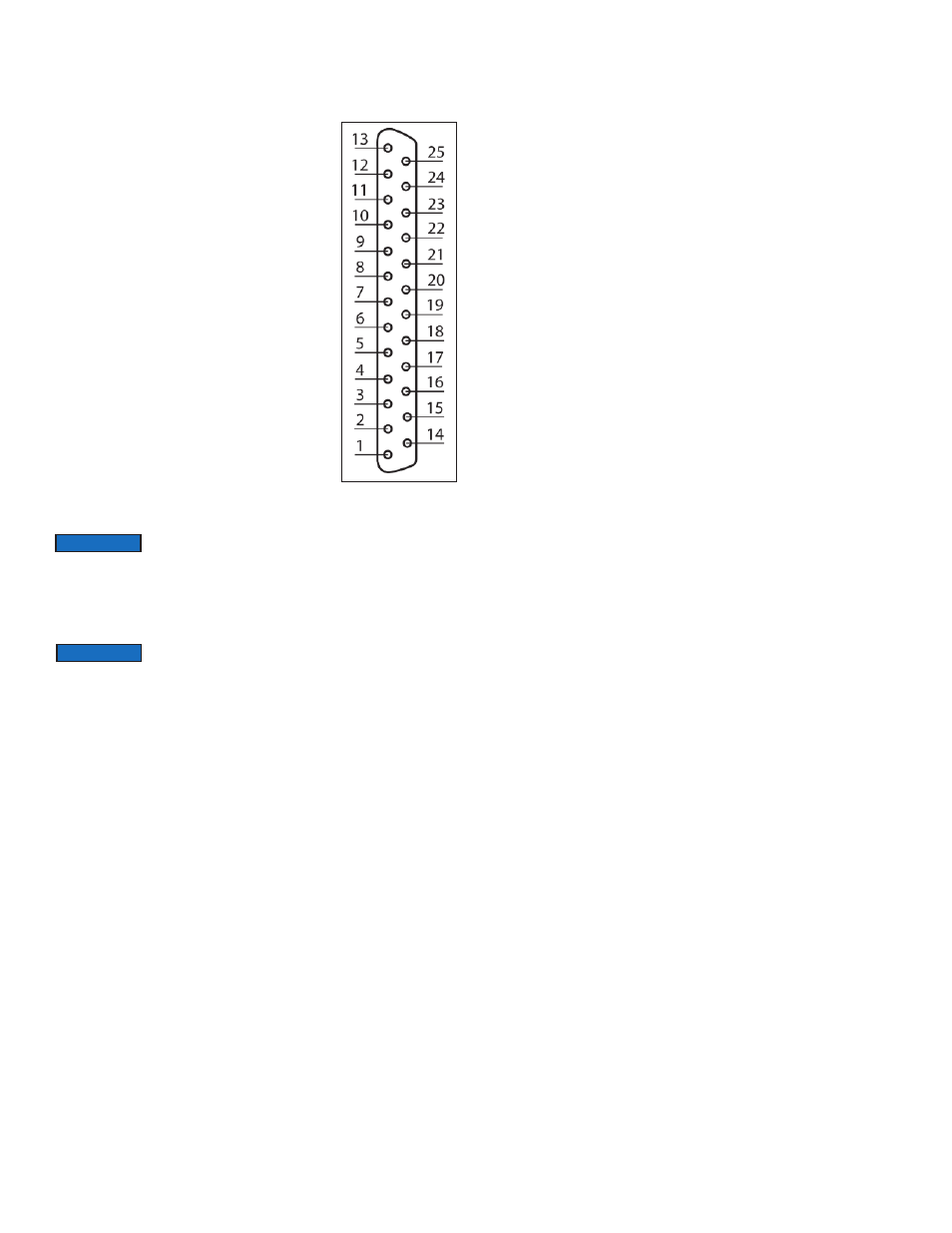

PIN

FUNCTION

1

+15 Vdc (Optional +12 or +24 Vdc) Power Supply

2

0 to 5 Vdc or 4 to 20 mA Flow Signal Output

3

0 to 5 Vdc or 4 to 20 mA Temperature Signal

Output (Optional)

4

0 to 5 Vdc or 4 to 20 mA Pressure Signal

Output (Optional)

5

(reserved)

6

(reserved)

7

(reserved)

8

Relay No. 1 - Common Contact

9

Relay No. 1 - Normally Open Contact

10

Relay No. 2 - Normally Closed Contact

11

RS485 (-) (Optional RS232 TX)

12

(No Connection)

13

Common

14

-15 VDC Power Supply (Only for ±15Vdc option)

15

Common, Signal Ground For Pin 2

(4 to 20 mA return)

16

Common, Signal Ground For Pin 3

(4 to 20 mA return)

17

Common, Signal Ground For Pin 4

(4 to 20 mA return)

18

Common, Power Supply (- DC power for

12 and 24 Vdc)

19

Common

20

RS232 Signal GND (RS-485 GND Optional)

21

Relay No. 1 - Normally Closed Contact

22

Relay No. 2 - Common Contact

23

Relay No. 2 - Normally Open Contact

24

RS485 (+) (Optional RS232 RX)

25

Chassis Ground

The (+) and (-) power inputs are each protected by a 400 mA M (medium time-lag)

resettable fuse. If a shorting condition or polarity reversal occurs, the fuse will cut

power to the flow transducer circuit. Disconnect the power to the unit, remove the

faulty condition, and reconnect the power. The fuse will reset once the faulty

condition has been removed. DC Power cable length may not exceed 9.5´ (3

meters).

Use of the GFM3/4 flow transducer in a manner other than that specified in this

manual or in writing from Dwyer

®

Instruments, Inc, may impair the protection

provided by the equipment.

3. PRINCIPLE OF OPERATION

The stream of gas entering the Mass Flow transducer is split by shunting a small

portion of the flow through a capillary stainless steel sensor tube. The remainder of

the gas flows through the primary flow conduit. The geometry of the primary conduit

and the sensor tube are designed to ensure laminar flow in each branch. According

to principles of fluid dynamics, the flow rates of a gas in the two laminar flow

conduits are proportional to one another. Therefore, the flow rates measured in the

sensor tube are directly proportional to the total flow through the transducer. In

order to sense the flow in the sensor tube, heat flux is introduced at two sections of

the sensor tube by means of precision wound heater sensor coils. Heat is

transferred through the thin wall of the sensor tube to the gas flowing inside. As gas

flow takes place heat is carried by the gas stream from the upstream coil to the

downstream coil windings. The resultant temperature dependent resistance

differential is detected by the electronic control circuit. The measured gradient at

the sensor windings is linearly proportional to the instantaneous rate of flow taking

place. An output signal is generated that is a function of the amount of heat carried

by the gases to indicate mass molecular based flow rates. Additionally, the GFM3/4

model Mass Flow Meter incorporates a Digital Signal Processor (DSP) and non-

volatile memory that stores all hardware specific variables and up to 10 different

calibration tables. Multi parameter flow meters provide accurate data on three

different fluid parameters:

• flow

• pressure

• temperature

The flow rate can be displayed in volumetric flow or mass flow engineering units for

standard or actual (temperature, pressure) conditions. Flow meters can be

programmed locally via the four button keypad and LCD, or remotely, via the RS-

232/RS-485 interface. GFM3/4 flow meters support various functions including:

flow totalizer, flow, temperature, pressure alarms, automatic zero adjustment, 2

SPDT relays output, 0 to 5 Vdc / 0 to 10 Vdc / 4 to 20 mA analog outputs for flow,

pressure and temperature.

4. SPECIFICATIONS

GFM3

Service: Clean gases compatible with wetted parts.

Wetted Materials: 316 SS, 416 SS; Fluoroelastomer, Buna-N, EPR or PTFE O-

rings.

Accuracy: ±1% FS.

Repeatability: ±0.25% FS.

Response Time: 0.6 to 1.0 s to within ±2% of setpoint over 20 to 100% FS.

Output Signal: Linear 0 to 5 VDC (3000 Ω min. load impedance); 0 to 10 VDC

(6000 Ω min. load impedance); 4 to 20 mA (500 Ω max. loop resistance).

Max. Particulate Size: 5 microns.

Temperature Limits: Ambient: 32 to 122°F (0 to 50°C); Dry Gases: 14 to 122°F (-

10 to 50°C).

Power Supply: ±12 VDC; ±15 VDC; ±24 VDC.

Process Connections: 1/8˝ compression fitting for flow rates ≤ 10 L/min; 1/4˝ for ≤

50 L/min; 3/8˝ for ≤ 100 L/min.

Pressure Limits: 500 psi (35 bar).

Leak Integrity: 1 x 10

-9

smL/sec of helium.

Display: 128 x 64 graphic LCD with backlight.

GFM4

Service: Clean gases compatible with wetted parts.

Wetted Materials: 316 SS, 416 SS; Fluoroelastomer, Buna-N, EPR or PTFE O-

rings.

Accuracy: ±1% FS.

Repeatability: ±0.25% FS.

Response Time: 0.6 to 1.0 s to within ±2% of setpoint over 20 to 100% FS.

Output Signal: Linear 0 to 5 VDC (3000 Ω min. load impedance); 0 to 10 VDC

(6000 Ω min. load impedance); 4 to 20 mA (500 Ω max. loop resistance).

Max. Particulate Size: 5 microns.

Temperature Limits: Ambient: 32 to 122°F (0 to 50°C); Dry Gases: 14 to 122°F (-

10 to 50°C).

Power Supply: ±12 VDC; ±15 VDC; ±24 VDC.

Process Connections: 1/8˝ compression fitting for flow rates ≤ 10 L/min; 1/4˝ for ≤

50 L/min; 3/8˝ for ≤ 100 L/min.

Pressure Limits: 200 psia (13.79 barA).

Leak Integrity: 1 x 10

-9

smL/sec of helium.

Display: 128 x 64 graphic LCD with backlight.

In general, "D" Connector numbering patterns are

standardized. There are, however, some connectors with

nonconforming patterns and the numbering sequence on your mating

connector may or may not coincide with the numbering sequence shown in our

pin configuration table above. It is imperative that you match the appropriate wires

in accordance with the correct sequence regardless of then particular numbers

displayed on the mating connector.

NOTICE

Make sure power is OFF when connecting or disconnecting

any cables in the system.

NOTICE

Figure b-1, GFM3/4 Pin "D"

Connector Configuration

Page 4