Dwyer GFM4 User Manual

Page 5

* Flow rates are stated for Nitrogen at STP conditions [i.e. 70°F (21.1°C) at 1

atm]. For other gases use the K factor as a multiplier from APPENDIX 2.

5. OPERATING INSTRUCTIONS

5.1 - Preparation and Warm Up

It is assumed that the Digital Mass Flow Meter has been correctly installed and

thoroughly leak tested as described in section 2. Make sure the flow source is OFF.

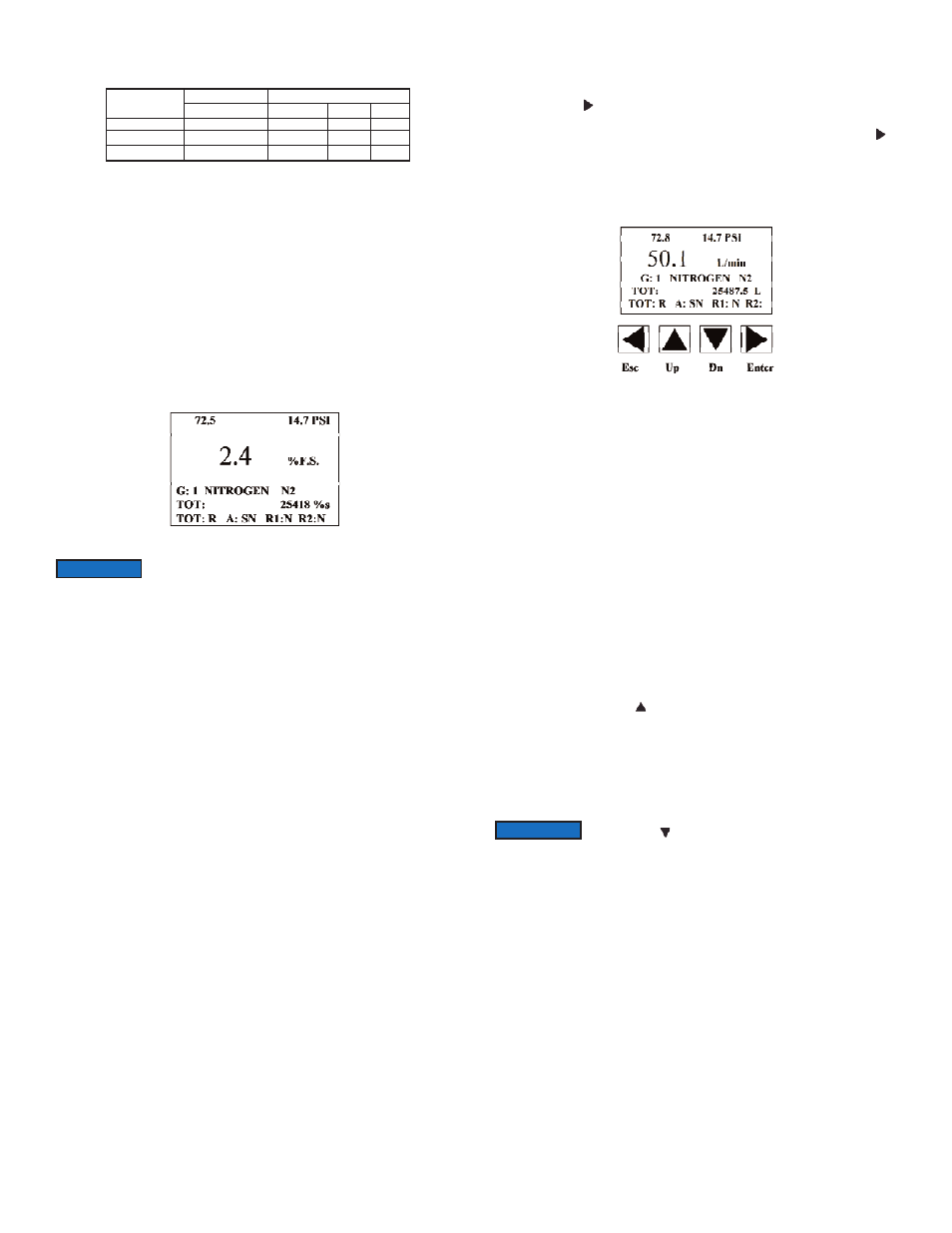

When applying power to a flow meter, within the first two seconds you will see on

the LCD display: the product name, the software version, and revision of the

EEPROM table. After two seconds the LSD display switches to the main screen

with the following information:

• Temperature and Pressure reading (for models GFM4 only).

• Mass Flow reading in current engineering units.

• Current Gas Table and Gas Name.

• Totalizer Volume reading in current volume based engineering units.

• Totalizer , Alarm, and Relays status.

GFM3/4 Main Screen

During initial powering of the GFM3/4 transducer, the flow output signal will be

indicating a higher than usual output. This is an indication that the GFM3/4

transducer has not yet attained its minimum operating temperature. This condition

will automatically cancel within a few minutes and the transducer should eventually

zero.

5.2 - Swamping Condition

If a flow of more than 10% above the maximum flow rate of the Mass Flow Meter

is taking place, a condition known as "swamping" may occur. Readings of a

"swamped" meter cannot be assumed to be either accurate or linear. Flow must

be restored to below 110% of maximum meter range. Once flow rates are lowered

to within calibrated range, the swamping condition will end. Operation of the meter

above 110% of maximum calibrated flow may increase recovery time. -

5.3 - Programming GFM3/4 using LCD and Keypad

All features of the flow meter can be accessed via the local four button keypad and

LCD. The LCD incorporates an energy-saving auto shut-off backlit feature. If

enabled, after 15 minutes of operation without user intervention the LCD backlight

turns off. In order to turn on the LCD backlight press any key on the keypad. The

LCD backlight energy-saving auto shut-off feature can be disabled or enabled by

user (see p. 5.3.12 "LCD backlight Energy-saving Setting").

5.3.1 - Changing Units of Measurement for Temperature and Pressure

Reading

By default after power up, the temperature reading is displayed in °F and pressure

in PSI. Pressing ( ) [Enter] button from main screen will alter the units of measure

to °C for temperature and kPa for pressure reading respectively. In order to change

units of measure back to °F for temperature and PSI for pressure, press ( )

[Enter] button while in the main screen one more time.

5.3.2 - Monitoring GFM3/4 Peripheries Settings

The last row at the bottom of the main LCD screen reflects settings and status for

Totalizer, Flow Alarm, and Relays (see Figure b-2).

Figure B-2

Totalizer Status:

TOT: R - totalizer is running (Enabled).

TOT: S - totalizer is stopped (Disabled).

Flow Alarm Status:

A: S

- flow alarm is disabled.

A: R,N

- flow alarm is enabled and currently there are no alarm conditions.

A: R,L

- flow alarm is enabled and currently there is Low alarm condition.

A: R,H

- flow alarm is enabled and currently there is High alarm condition.

Relay Settings:

N - No assignment (relay is not assigned to any events).

H - High Flow Alarm condition.

L - Low Flow Alarm condition.

R - Range between High and Low Flow Alarm condition.

T - Totalizer reached set limit.

A - High Temperature Alarm condition.

B - Low Temperature Alarm condition.

C - High Pressure Alarm condition.

D - Low Pressure Alarm condition.

Continued pressing of the ( ) [Up] button from the main screen will switch the

status line to display the following information:

- Calibrated full-scale range in standard L/min for current Gas Table.

- Device Digital Communication interface type (RS-485 or RS-232).

- Device RS-485 address (two hexadecimal characters).

- Device Zero DAC counts (for troubleshooting purposes).

- Device Sensor Average ADC counts (for troubleshooting purposes).

- Device Sensor Compensated ADC counts (for troubleshooting purposes).

Model

GFM3/4-X-010

GFM3/4-X-050

GFM3/4-X-100

Flow Rate

(std liters/min)

up to 10

50

100

Maximum Pressure Drop

(mm H

2

0)

25

2200

5500

(psid)

0.04

3.23

8.08

(kPa)

0.276

22.3

55.7

Table IV - Pressure Drops

¡

F

Allow the Digital Mass Flow Meter to warm-up for a minimum of

15 minutes.

NOTICE

¡

F

Pressing the ( ) [Dn] button from any of the status line will

switch the status display to one step back.

NOTICE

Page 5