Step 3, Step 2 – Advanced Protection XRL User Manual

Page 6

6

For sensitive electronics and computer systems, we

recommend that the ground impedance measurement be

as low as possible. When metallic raceway is used as an

additional grounding conductor, an insulated grounding

conductor should be run inside the raceway and sized per

the NEC

®

. Adequate electrical continuity must be maintained

at all raceway connections. Do not use isolating bushings

to interrupt a metallic raceway run.

A separate isolated ground for the SPD is NOT recommended.

Proper equipment connections to grounding system and

ground grid continuity should be verified via inspections and

testing on a regular basis as part of a comprehensive electrical

maintenance program.

On 4-Wire Power Systems, neutral to ground bonding (Main

Bonding Jumper) must be installed per the NEC

®

. Failure

to do so WILL damage SPDs.

Internal Mounting of XR and XW Component SPD

XR’s and XW’s are essentially XA’s without enclosures. XR’s

and XW’s are intended for installation within host electrical

equipment having suitable enclosures.

The experienced integrator will appreciate the simplicity

of XR/XW. XR/XW’s are Type 4 SPDs and have been

evaluated by UL for use as Type 1 (or Type 2) SPDs

when installed in appropriate enclosures. All UL required

safety testing is complete without needing additional

safety apparatus. Contact factory for UL file Engineering

Considerations. Mount SPD in appropriate enclosure,

mount Diagnostic Display in appropriate location and follow

appropriate instructions, including short leads. UL evaluation

within your completed product should be easy and trouble

free. Do not Hi-Pot test with SPD in circuit.

In many instances, a disconnecting means is appropriate

for future service. A breaker serves this function, as well

as provides overcurrent protection to the connecting

conductors. If a breaker or optional Disconnect Switch are

not used, consider a disconnect or safety switch having

appropriate SCCR rating including any required overcurrent

protection. Line side is likely to require a UL 98 switch where

load side is likely to require a UL 508 (or UL 98) switch.

This may be more time consuming, more expensive and

physically larger than anticipated. APT offers an optional

Disconnect Switch that has been UL evaluated as part of the

SPD. The optional Disconnect Switch is fully engineered and

almost certainly easier, smaller and less expensive. Please

contact APT Technical Support as appropriate.

Mounting Diagnostic Display: Mount the Display in a

user-friendly location, with consideration to weather and

vandalism. Dimensions are in Figure 4 (page 7). A Display

with a 6’ connector cable is typically included. Longer lengths

are available. The Display is also mountable directly on the

XR/XW module (shorter cables required). The standard

Display includes mounting thru-holes and is not weather

resistant. Contact factory for weather resistant NEMA 4 rated

Display (with mounting studs instead of thru-holes and label

material including UL 746C(f1) & UL 94-5VA flame rating).

UL 1283 required language concerning the installation

of EMI Filters

a) An insulated grounding conductor that is identical in size

and insulation material and thickness to the grounded and

ungrounded circuit supply conductors, except that it is green

with or without one or more yellow stripes, is to be installed

as part of the circuit that supplies the filter. Reference should

be made to Table 250-122 of the National Electrical Code

regarding the appropriate size of the grounding conductor.

b) The grounding conductor mentioned in item a is to

be grounded to earth at the service equipment or other

acceptable building earth ground such as the building frame

in the case of a high-rise steel-frame structure.

c) Any attachment-plug receptacles in the vicinity of the

filter are to be of a grounding type, and the grounding

conductors serving these receptacles are to be connected

to earth ground at the service equipment or other acceptable

building earth ground such as the building frame in the case

of a high-rise steel-frame structure.

d) Pressure terminal or pressure splicing connectors and

soldering lugs used in the installation of the filter shall be

identified as being suitable for the material of the conductors.

Conductors of dissimilar metals shall not be intermixed in a

terminal or splicing connector where physical contact occurs

between dissimilar conductors unless the device is identified

for the purpose and conditions of use.

Optional Flush Mount Installation Considerations

The XA & XB are approximately 6” deep. The unit will not

mount flush unless there is at least 6” of depth clearance.

The XA & XB are not designed to mount flush on a typical

2 x 4 stud wall.

Back Flange Mounting: Mount as close as possible to

protected panel. Create a wall opening slightly larger than

SPD. See Figure 4. Configure a robust backing plate inside

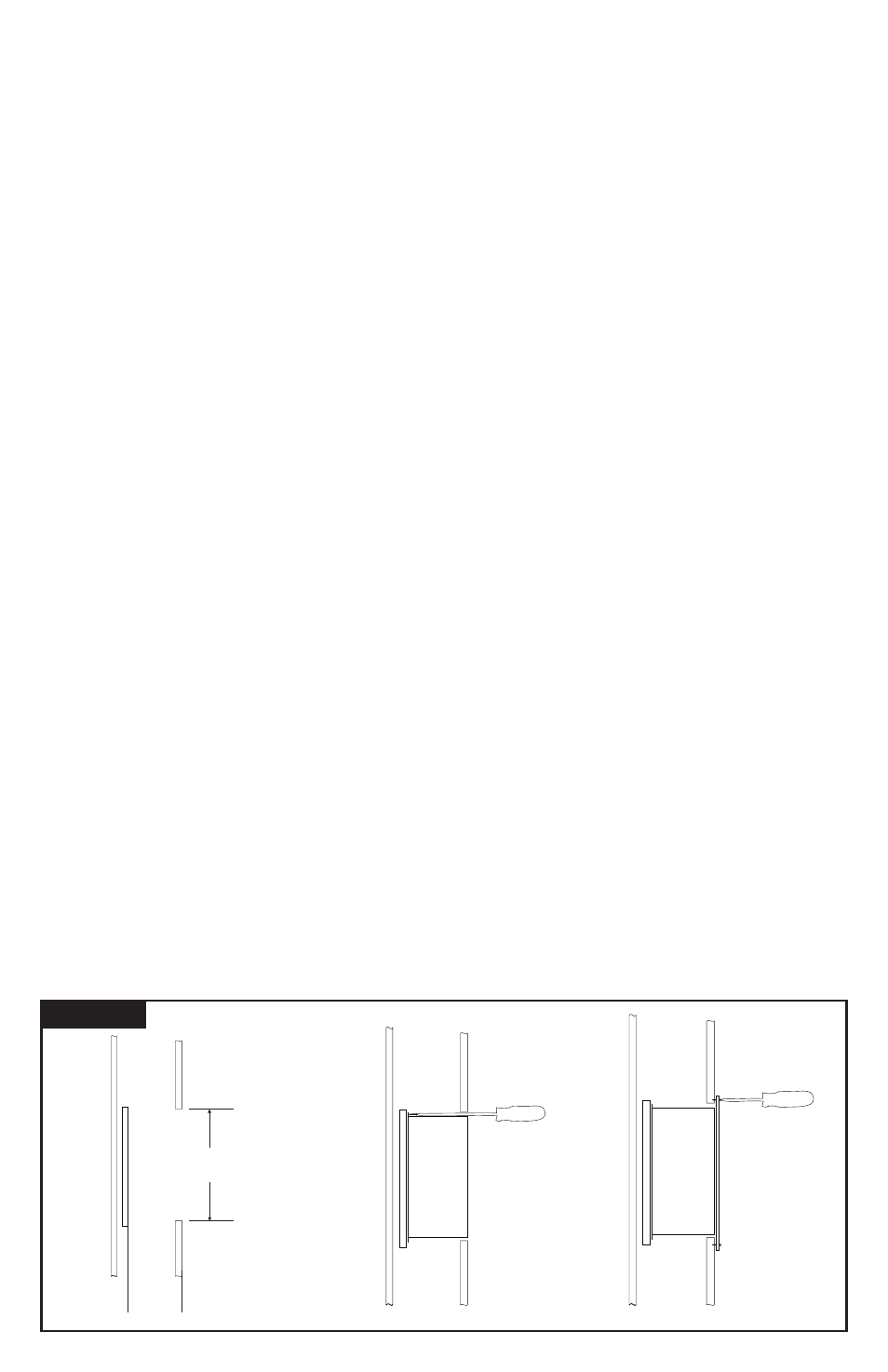

FLUSH MOUNT INSTALLATION

Figure 3

STEP 2:

Mount SPD

STEP 3:

Install Flush

Mount Plate

& Cover

Cutout slightly larger than

SPD base

Mounting Plate

6 1/16” from

outside of front

wall

STEP 1:

Prepare Wall

- Must support

25-55lbs