No dry contacts nc nc c no c – Advanced Protection XRL User Manual

Page 11

11

appreciate SPD safety benefits on smoke detectors,

medical equipment, security equipment, etc. Similarly,

some AHJ’s appreciate the financial distress of failed

microelectronic loads.

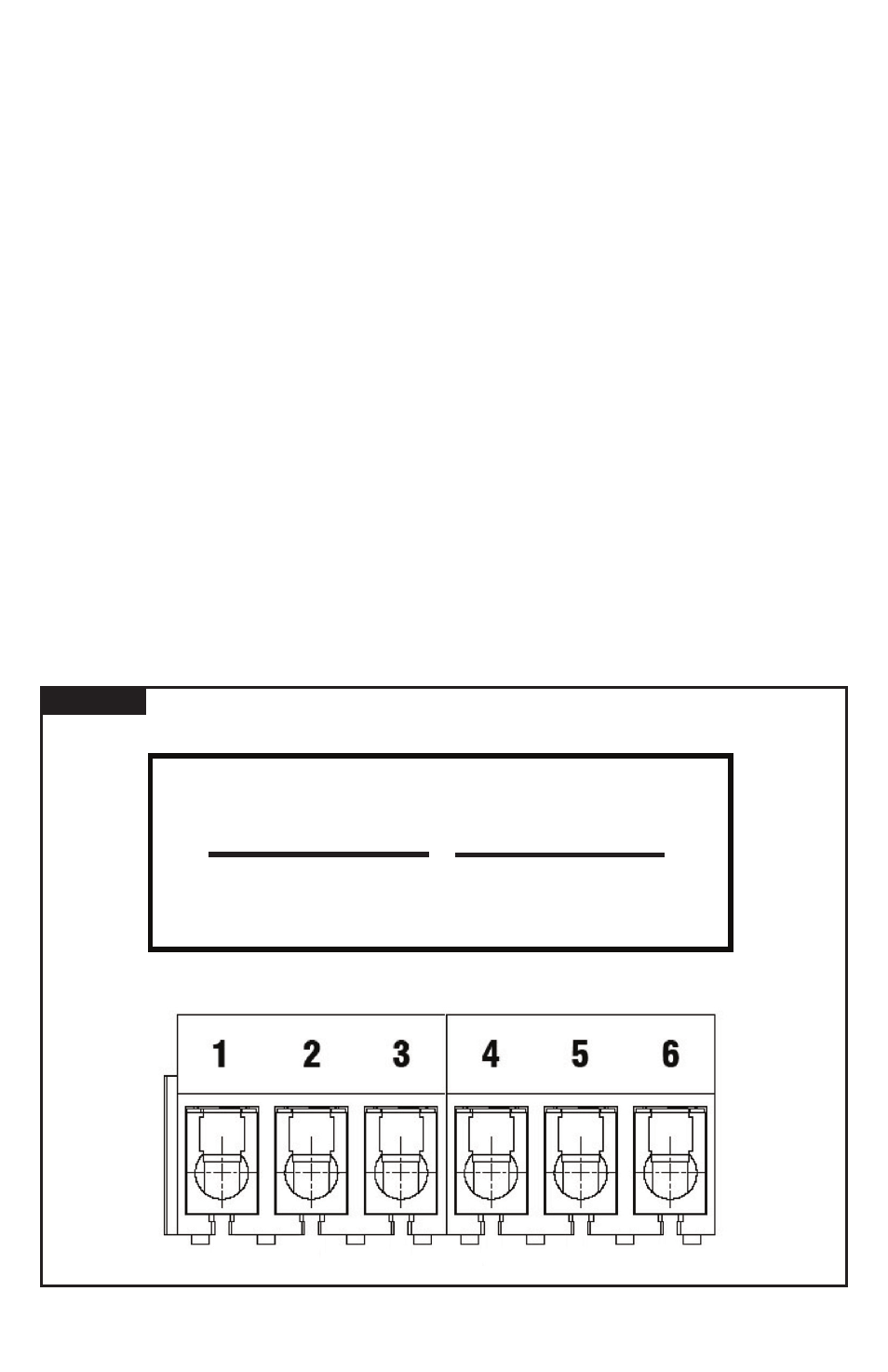

Dry Contact Option

Two sets of Form C dry contacts are included with the

Dry Contact option. Dry Contacts change state during

inoperative conditions, including loss of power. Any status

change can be monitored elsewhere via Dry Contacts.

A Terminal Block includes two sets of Normally Open

(N.O.) and Normally Closed (N.C) contacts. Both sets of

contacts operate the same. This is shown in Figure 10. A

typical application using a Normally Closed configuration

would connect to one set of the N.C. and Common

terminals. During an inoperative condition, the SPDs dry

contact would change state from normally closed to open.

We generally suggest the Normally Closed configuration

because it will detect a wiring defect, such as cut wire(s),

where N.O. will not.

Please note: Dry Contacts are designed for low voltage

or control signals only.

▪

Maximum switching current is 5A

▪

Maximum switching voltage is 240V DC or AC.

▪

Higher energy applications require additional relay

implementation outside the SPD.

An optional Remote Monitor accessory is available to

provide visual and audible status. The Remote Monitor will

consume one of the two sets of Dry Contacts.

Remote Monitor Accessory Option

A Remote Monitor is available for remote annunciation.

It requires a standalone 120V power source (wall plug

transformer) and uses one set of Form C dry contacts. The

Remote Monitor can be configured to monitor several APT

SPDs simultaneously. Installation is detailed in a separate

document. Contact factory as appropriate.

Retro-fit Into Existing Panel with No Available

Breaker Positions

These can be difficult with limited options.

Follow all applicable Codes:

• Consider consolidating loads in a manner that might free

breaker positions.

• A ten foot tap rule in NEC

®

240.21(B)(1) allows you to tap

the bus as long as the tap conductors are rated at least

10% of the ampacity of the panel. This works well if the

panel is about 600A or less: Tap the bus, run short 6 AWG

leads to the SPD. An SPD with a Disconnect Switch allows

for easier SPD servicing in the future. If the panel starts

getting large (>800A), then the conductor size increases,

which may also become too large to fit into the SPD lugs

or too cumbersome to work with. In that case, consider

tapping the bus per NEC

®

240.21(B)(1). Run appropriate

size conductors to a safety switch fused to 60A. Mount the

SPD immediately adjacent to the safety switch. Connect

SPD to the load side of the safety switch with 6 AWG.

Keep all leads as short as possible.

• Install on Line Side by taking advantage of Type 1 SPD

rating. Consider an SPD with a Disconnect Switch.

• In no-win situations, consider asking the Authority

Having Jurisdiction (AHJ) for guidance. Some AHJ’s

NO

DRY CONTACTS

NC NC C NO

C

DRY CONTACT OPTION

Figure 10