Xb h/w/d (in. / mm.) weight, Xr h/w/d (in. / mm.) weight, Xw h/w/d (in. / mm.) weight – Advanced Protection XRL User Manual

Page 4

4

Unpacking & Preliminary Inspection

Inspect the entire shipping container for damage or signs

of mishandling. Remove the packing materials and further

inspect the unit for any obvious shipping damages.

If any damage was found and is a result of shipping

or handling, immediately file a claim with the shipping

company and forward a copy to APT.

Storage Environment

This SPD should be stored in a clean, dry environment.

Storage temperature range is -40°C (-40°F) to +60°C

(+140°F). Avoid exposure to high condensation.

PRE-INSTALLATION & INSTALLATION PLANNING

Operating Environment

The standard unit uses a Type 1/12/3R/4 enclosure.

Non-metallic polycarbonate 4X, stainless steel and Type

1 flush-mount or pull box enclosures are available as

options. Before installing, ensure that your enclosure type

and application are appropriate per NEMA 250 with regard

to moisture, dirt, excessive dust, flammable materials or

atmospheres, corrosive vapors, etc. Please consult factory

if enclosure needs to be changed.

This SPD is designed in an ambient temperature range

of -40°C (-40°F) to +60°C (+140°F) with a relative

humidity of 0% to 95% (non-condensing). Excessive

temperature may inadvertently operate internal thermal

overtemperature protectors.

On rare occasions in high temperature climates, SPDs

inside clear cover polycabonate enclosures have

experienced internal temperatures exceeding 200°F

(94°C). We recommend positioning the unit so that the

clear front avoids direct summer sunlight by shading or

not facing west.

Line Side versus Load Side Installation

The XA & XB family SPDs are tested and qualified as

Type 1 SPDs per UL 1449 Third Edition and 2008 NEC

®

.

This SPD can be installed on the Line Side of the service

overcurrent device per 2008 NEC

®

Article 285. Type 1

SPDs may also be installed in Type 2 applications. As

a generalization, it is more practical to install as Type 2

on load side of main overcurrent device for maintenance

reasons. Such installations would be similar to traditional

TVSS installations. (Note: cUL models are Type 2 due to

different cUL criteria.)

XR and XW SPD modules are Type 4 components that

have been evaluated by UL for use in Type 1 applications.

(XR’s and XW’s are essentially XA’s without enclosures for

installation within host electrical equipment.)

There may be circumstances where Line Side installation

is desirable. Follow all applicable Code requirements for

Line Side installation. We generally recommend that the

SPD be installed with a disconnecting mechanism for

servicing purposes.

Tip: APT offers an optional Disconnect Switch that has been

UL evaluated as part of the SPD. This includes SCCR and

Line Side suitability. If you do not use the APT Disconnect

option, select a disconnect switch rated for line side (UL

98) having appropriate SCCR rating including any required

overcurrent protection. This may be more time consuming

and expensive than anticipated. The optional Disconnect

Switch is fully engineered and almost certainly easier, smaller

and less expensive. Please contact APT Technical Support

as appropriate.

Audible Noise

SPD background noise is negligible or non-existent, and

does not restrict the location of installation.

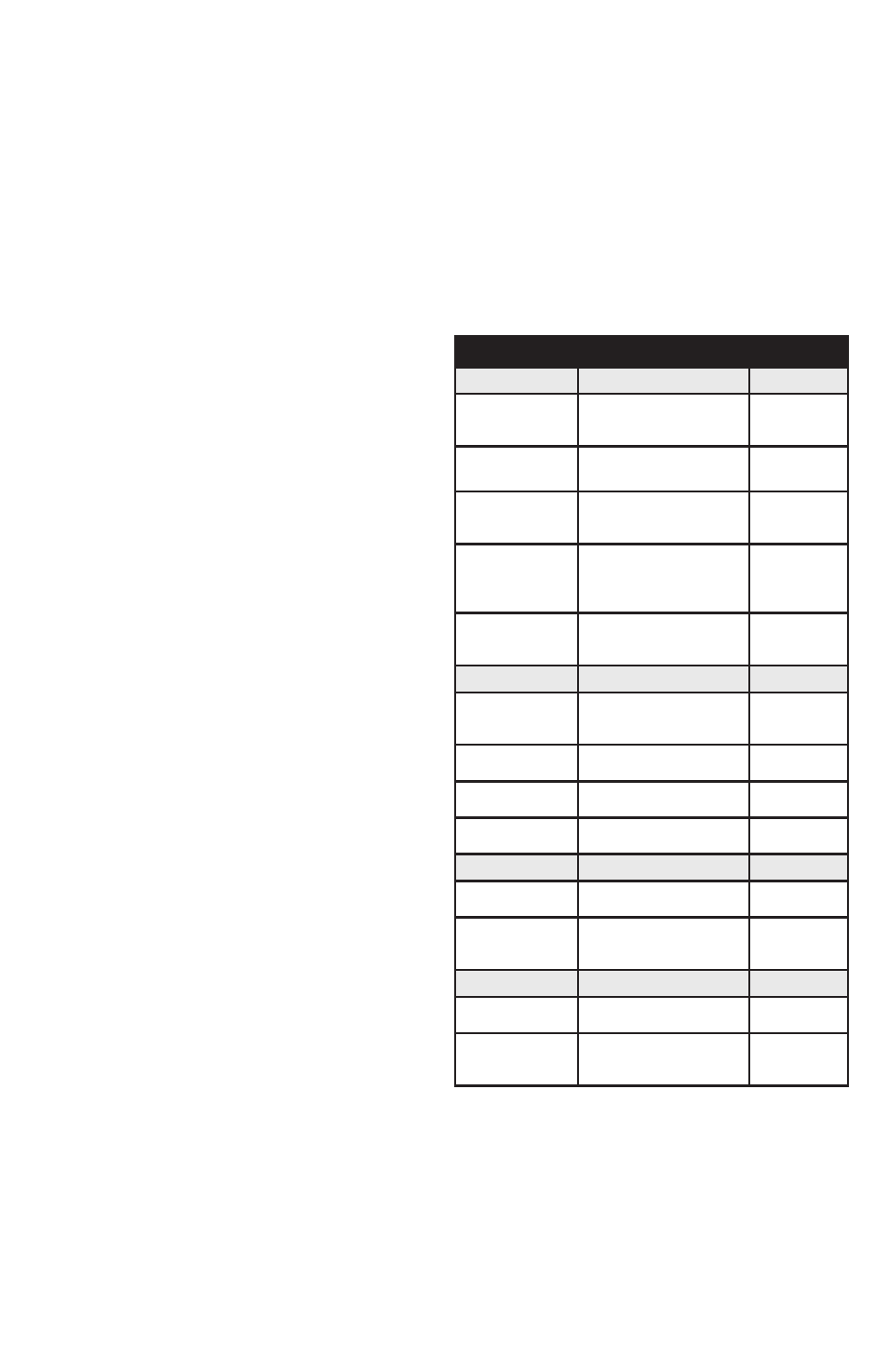

Mounting, Dimensions, and Weight

The XA & XB series include enclosures and are intended for

wall mounting. The XR & XW series are component SPDs

intended for installation within other electrical gear already

having enclosures. See Table 2. Mechanical drawings are

included in back of this manual (page 12).

TABLE 2: DIMENSIONS & WEIGHTS

XA

H/W/D (in. / mm.)

Weight

Standard (and w/

Opt. Disc. Switch

& <300kA)

12"x12"x6.5"

(305x305x165)

23 lbs

(10.4 kg)

With Opt. Disc.

Switch & >300kA

16"x14"x6.5"

(406x356x165)

32 lbs

(14.5 kg)

4X Non-Metallic

(std.)

(>300kA w/disc.)

14"x12"x7" (356x305x178)

16"x14"x7" (406x356x178)

14 lbs (6.4)

21 lbs (9.5)

4X Stainless

(>300kA w/disc.)

12"x12"x7.5"

(305x305x191)

16"x14"x7.5"

(406x356x191)

24 lbs (10.9)

33 lbs (15)

Pullbox & Flush

mount

(>300kA w/disc.)

12"x12"x6" (305x305x152)

16"x14"x6" (406x356x152)

21 lbs (9.5)

29 lbs (13.2)

XB

H/W/D (in. / mm.)

Weight

Standard

(includes Disc.

Switch)

20" x 20" x 7.5"

(508 x 508 x 191)

52 lbs

(23.6 kg)

4X Non-Metallic

24" x 24" x 8"

(610 x 610 x 203)

52 lbs

(23.6 kg)

4X Stainless

20" x 20" x 7.5"

(508 x 508 x 191)

53 lbs

(24 kg)

Pullbox & Flush

mount

20" x 20" x 6"

(508 x 508 x 152)

43 lbs

(19.5 kg)

XR

H/W/D (in. / mm.)

Weight

Standard

6.5" x 11" x 4.5"

(165 x 279 x 114)

5 lbs

(2.3 kg)

With Opt. Disc.

Switch on alum.

backplane

10.75" x 10.88" 4.5"

(273 x 276 x 114)

9 lbs

(4.1 kg)

XW

H/W/D (in. / mm.)

Weight

Standard

9" X 11" X 4.5"

(229 x 279 x 114)

7 lbs

(3.2 kg)

With Opt. Disc.

Switch on alum.

backplane

14.75" X 12.9" X 5.25"

(375 x 328 x 133)

11 lbs

(5 kg)

Service Clearance

Service clearance is needed at the front of the unit; 36

inches minimum is the required distance for clearance

pursuant to the NEC

®

.

Lead Lengths & Maximizing SPD Performance

SPDs must be located as close to the circuit as possible

to minimize parasitic losses. Surges are high current, high

frequency events that cause substantial voltage drops

across conductors. This hurts SPD performance. Use the

shortest & straightest possible leads. Pre-Plan installations