SHIMPO DAG-2000 User Manual

Page 30

DIGITAL AIR MICROMETER USERS MANUAL (Second Edition)

30

CHAPTER 8

MAINTENANCE

(1)

Please use alcohol for removing dirt on the main body.

If thinner is used, color will fade and become dull.

(2)

Filter will get clogged as a result of being used for long period of time.

Please replace the ELEMENT 2 years after start of use or when the pressure falls to 0.1MPa.

(3)

Cleaning of A/E converter

Trash could be sticking inside the air circuit as a result of being used for long period of time.

In case there is too much oil sticking, we recommend the use of the compressed air purifier.

① Please record the position of the front ZERO position/sensitivity adjustment tuner (distance from

the main body to the tip).

Master calibration will be easy after finishing cleaning.

② Turn the ZERO position/sensitivity adjustment tuner counterclockwise and pull out from the main

body.

③ Please inspect the O ring of the needle part. In case there is scratch, it should be replaced.

④ Please clean if the needle is dirty.

Please clean also the hole (

∅ 3) in contact with the needle using cotton buds soaked with alcohol.

⑤ Insert the needle into the main body.

If the screw seems to be loose, widen the split screw with a screw driver tip, etc.

Please be careful not to over bend.

⑥ Turn the needle clockwise and insert into the position initially recorded.

Please perform adjustment or master calibration through the ZERO position/sensitivity adjustment

tuner.

CHAPTER 9

CAUSES OF FAILURE AND COUNTERMEASURES

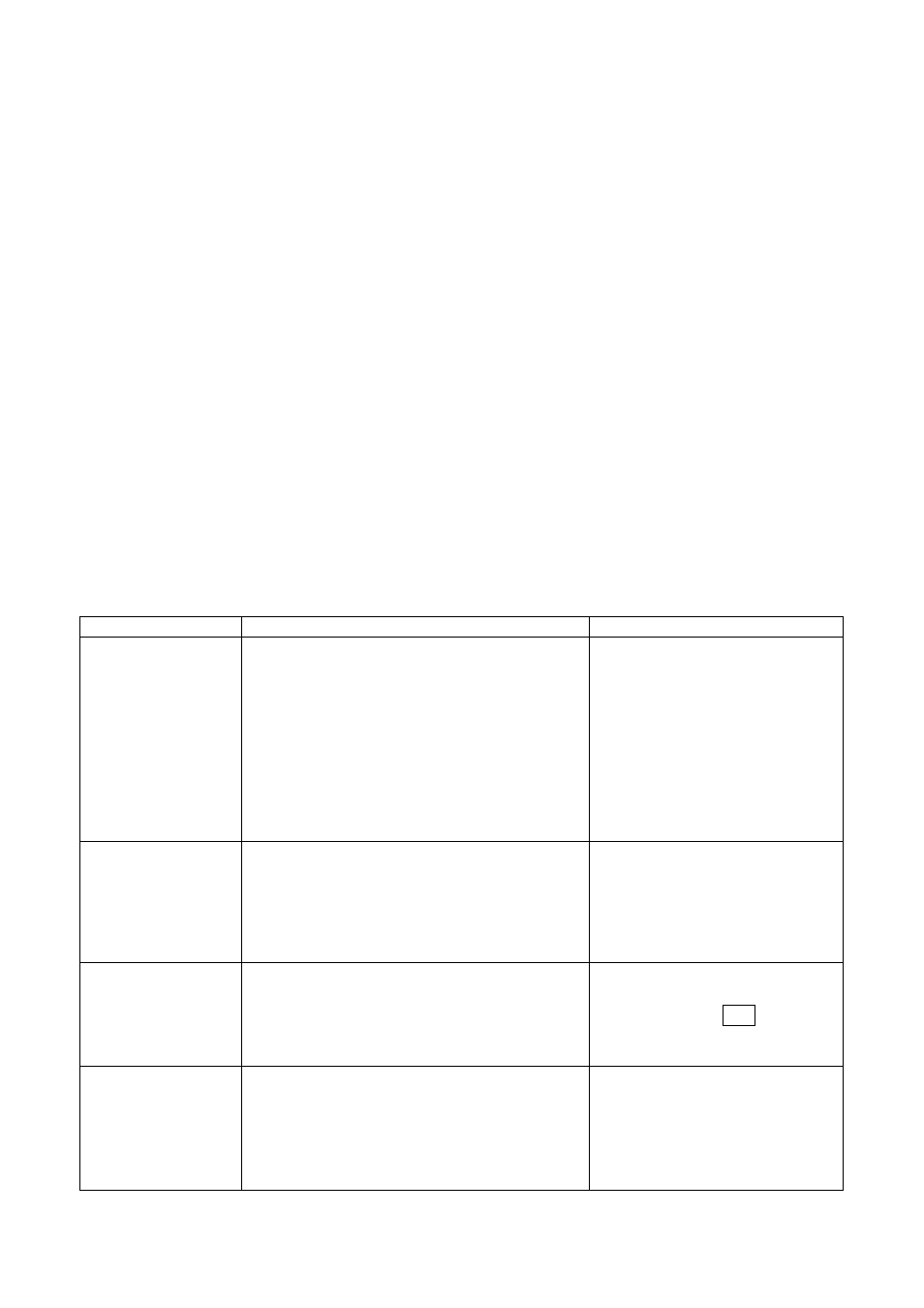

Phenomenon

Failure and adjustment NG location

Countermeasure

Repeatability

accuracy is not stable

① Supplied pressure is not stable

② Regulator function NG

③ Nozzle is worn out

④ There is leak in the piping, joint, etc.

⑤ Water and oil is mixed inside the main

body

① Set the source pressure of the

regulator to 300kPa or above.

② Overhaul or replacement of

regulator

③ Replace the nozzle with a

new one

④ Check for leak and then

tighten

⑤ Clean the main body

(use compressed air purifier)

ZERO position

adjustment tuner

does not work

① Supplied pressure is low or high

② There is leak in the piping, joint, etc.

③ Nozzle gap is too small

④ Nozzle gap is too big

① Set the regulator pressure

settings to 196kPa.

② Check for leak and then

tighten

Adjust to the appropriate gap

Main display does

not operate

① Proper power is not supplied

② ZERO position adjustment NG

③ In measurement value hold mode

Display color is green (dark) or red (dark)

④ In settings mode

① Supply AC85 ~ 264V

② Perform master calibration

③ Cancel using RST

④ End the settings mode

Display device does

not lit

① Power is not supplied

② Fuse is busted

③ Power/internal circuit failure

④ Display settings

① Supply AC85 ~ 264V

② Replace fuse (3A)

③ Request to maker for repairs

④ Change the settings item

[MainDisp]