KROHNE BATCHCONTROL 5014 C User Manual

Page 8

Installation and operating instructions

8 BATCHCONTROL

1.3 Installation

requirements

Items supplied with flowmeter

•

BATCHCONTROL IFM 5014C compact

flowmeter in the version as ordered

•

Installation and operating instructions,

as agreed

•

Certificate of system calibration data

(as agreed)

Excluding fitting accessories. Stud bolts,

gaskets, etc., to be provided by customer.

All operating data and function values

are factory set according to your order

specifications.

Requirements

Use in the food industry

The IFM 5014C is specifically suitable for use

in the food and beverage industry or similar

sterile processes.

The IFM 5014C is steam-resistant.

The measuring tube can be SIP or CIP

cleaned when in installed condition. During the

cleaning the meter(s) must be switched off to

maintain the reliability of the unit(s).

•

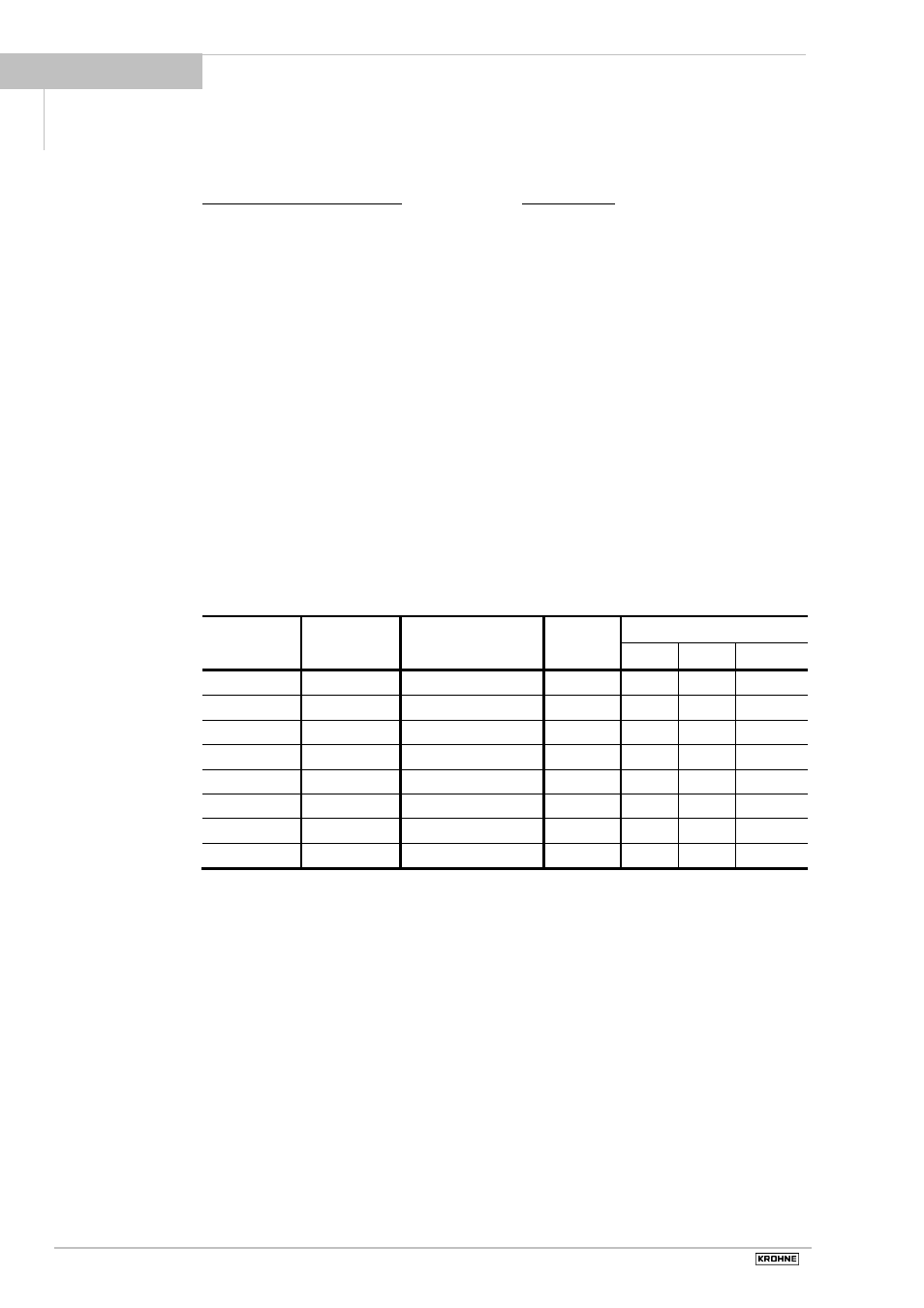

Operating pressure, type, and space

between pipe flanges: see Table.

•

Tighten stud bolts uniformly down to the

metal stop in diagonally opposed

sequence. See Table for type and number

of stud bolts.

•

Install meter vertically or in a slope due to

its conical in/outlet.

On DN 15 (

1

/

2

”) and DN 32 (1

1

/

4

” ) a

BATCHCONTROL with straight ceramic

tube is avaible.

DIN 2501

ANSI B 16.5

Space between

Bolts

Max torque

and JIS

pipe flanges

Nm

kpm

ft × lbf

DN 2.5

1

/

10

"

51.8 mm (2.04")

4 x M12

10

1.0

7.2

DN 4

1

/

8

"

51.8 mm (2.04")

4 x M12

10

1.0

7.2

DN 6

1

/

4

"

51.8 mm (2.04")

4 x M12

10

1.0

7.2

DN 10

3

/

8

"

51.8 mm (2.04")

4 x M12

10

1.0

7.2

DN

15

1

/

2

"

51.8 mm (2.04")

4 x M12

10

1.0

7.2

DN 25

1"

58.0 mm (2.28")

4 x M12

10

1.0

7.2

DN

32

1

1

/

4

“

83.0 mm (3.27“)

4 xM16

43

4.3

31.0

DN

40

1

1

/

2

"

83.0 mm (3.27")

4 x M16

43

4.3

31.0

1