KROHNE BATCHCONTROL 5014 C User Manual

Page 10

Installation and operating instructions

10 BATCHCONTROL

1.4 Installation of the primary head

1.4.1 Device description

•

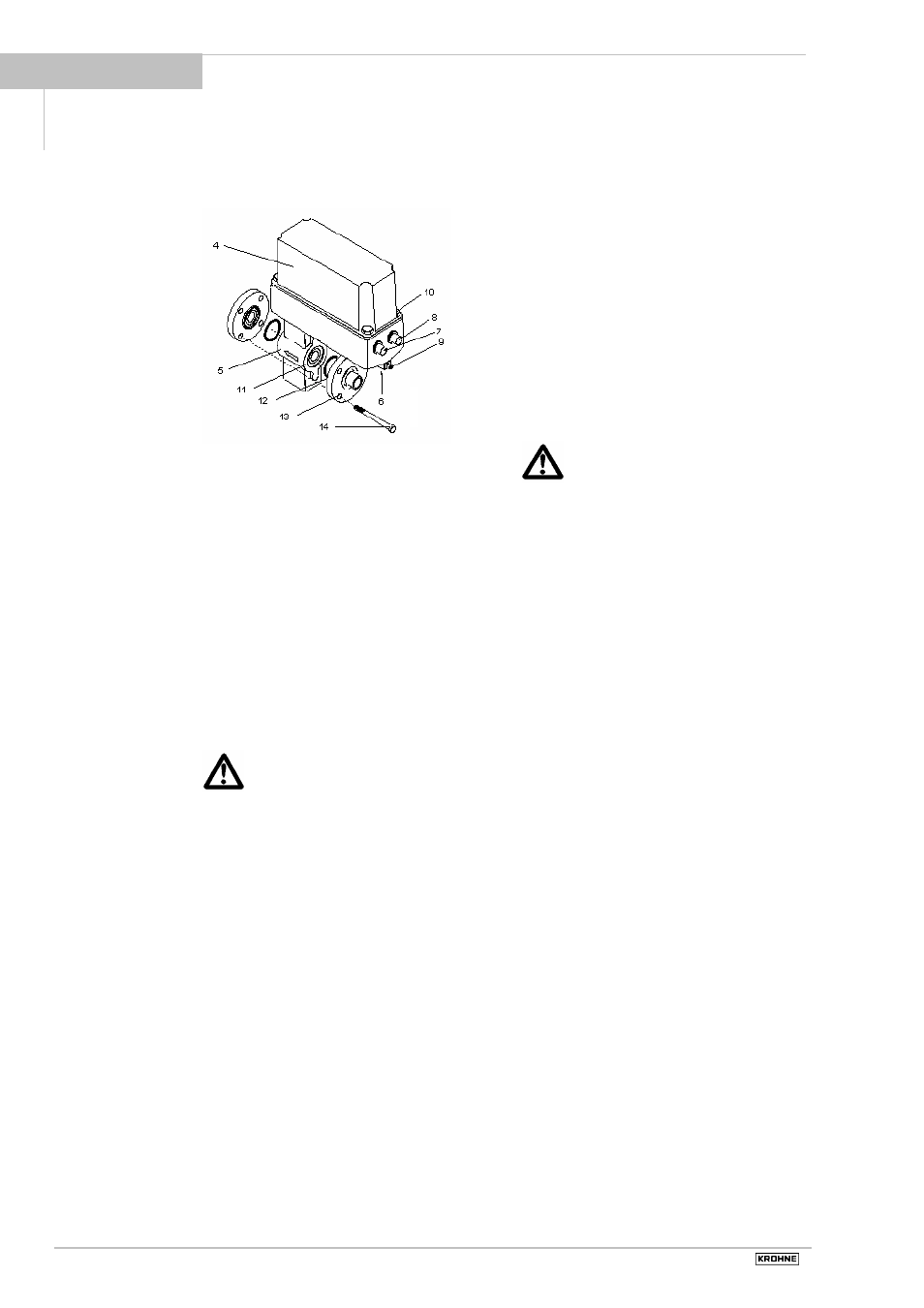

BATCHCONTROL IFM 5014C

4 Cover, signal converter

5 Primary head

7 Connector for the six in-/outputs

8 Connector for power and CAN Bus

9 U-clamp terminal for functional ground

10 Fastening screws for cover

11 Locating collar, primary head

•

Accessories from system manufacturer

12 O-ring gasket

13 Special pipe flange

14 Stud bolt with lock washer,

plain washer and nut

To facilitate servicing of the

primary head, please note the

following points:

•

It must be possible to shut off the flow

through the pipeline upsteam of the primary

head (provide shutoff valve),

•

Drain the pipe system before removing the

primary head (provide drain valve),

•

Support the pipeline on both sides of the

flowmeter when located in a long, freely

suspended section to facilitate removal of

the primary head.

1.4.2 Installation of the IFM 5014C

•

Position gaskets (12) in the pipe flanges.

•

Type and location of gaskets as specified

by the manufacturer of the filling machine

(see Sect. 1.3.2 “Centering of the primary

head”).

•

Insert primary head (5) between the pipe

flanges (13) in line with the pipe axis.

•

For spacing and location of the pipe

flanges, see Sect. 1.3 “Position of flanges”.

•

Press pipe flanges against flowmeter.

Centering ring of pipe flanges must

snap into place in the guide collar

(11) of the primary head.

•

Insert stud bolts (14) with washers into the

holes in the pipe flanges. Fit nuts to stud

bolts with lock washer.

•

Tighten stud bolts and nuts down to the

metal stop symmetrically. Check all bolts

after starting up the pipe system, and

retighten when any leaks show.

•

Connect ground conductor to U-clamp

terminal (9).

•

Connect power supply, CAN bus and

outputs to connector plugs (7, 8) on signal

converter housing (4).

See Section 2.2 and 2.3 for details of

electrical connection.

1