KROHNE BATCHCONTROL 5014 C User Manual

Page 17

Installation and operating instructions

17

BATCHCONTROL

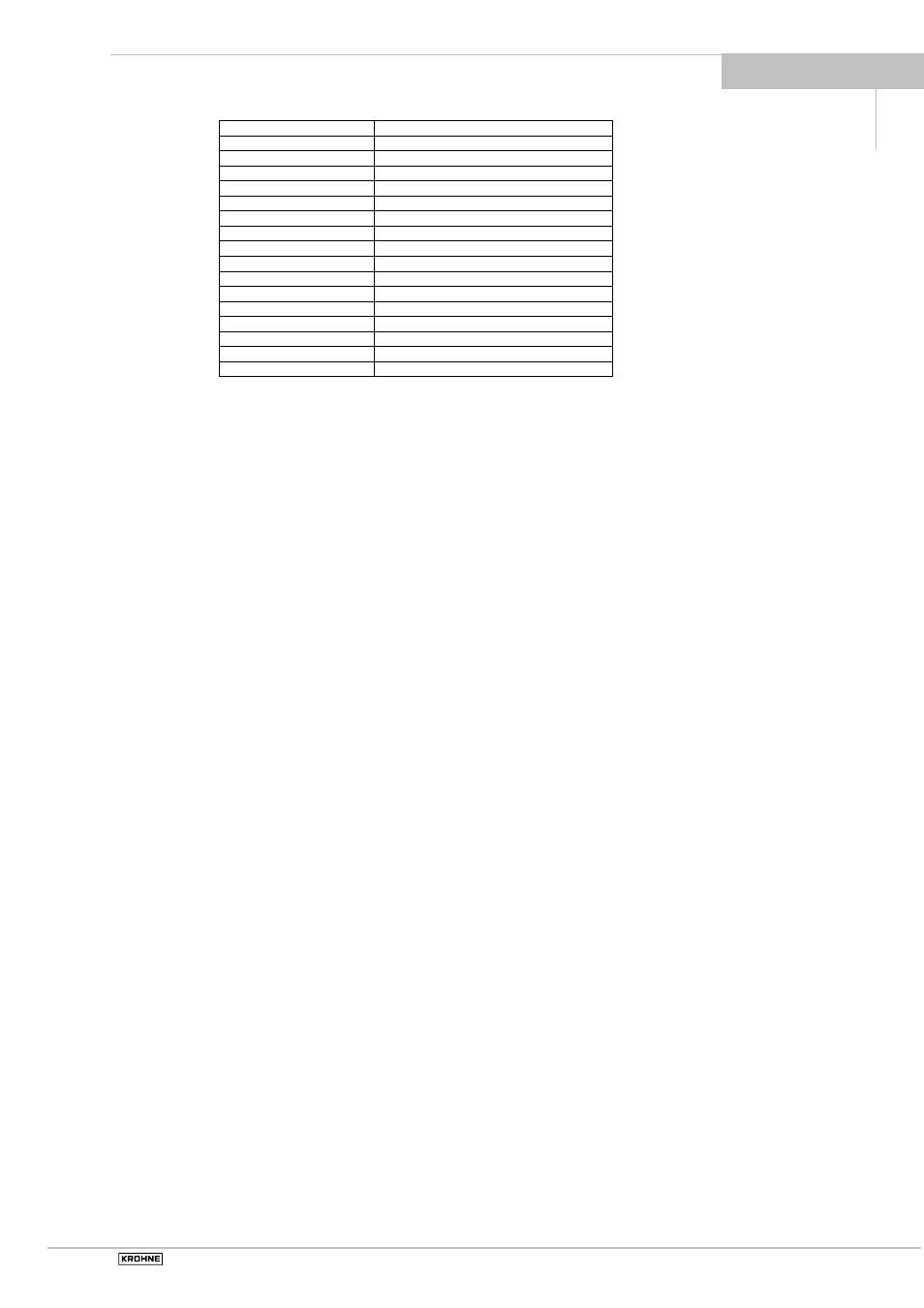

The object dictionary for the parameters is subdivided into the following groups:

Object number range

Description

10xxH

CAN open parameter

300xH

Flow sensor parameter

301xH

Electronic temperature sensor

302xH

Liquid temperature sensor

303xH

Function block 1

304xH

Function block 2

305xH

Function block 3

306xH

Function block 4

307xH

Function block 5

308xH

Function block 6

309xH Batching

30AxH CAN

parameter

32xxH

Customer specific 1 bit memory

33xxH

Customer specific 8 bit memory

34xxH

Customer specific 16 bit memory

35xxH

Customer specific 32 bit memory

The complete list of all parameters can be found at the end of the manual.

To be able to represent the variety of all possible messages on the bus, the CANopen definition

hasn't been used at the definition of the TPDOs and RPDOs. If this function is programmed, then

the device sends at every message in the first data byte a description and in the following bytes

the data. This shall be explained at an example:

The user needs every flow measurement for the analysis of the valve. With the parameter

3002.02 the PDO is defined. After this parameter was stored in the BATCHCONTROL

5014C, it sends the actual volume flow every 20 ms. The Telegramm starts in the first byte

with the descriptor (in this case 01H) followed by the measurement value in float format.

Many parameters can use the same PDO. The distinction of the data is made by the first

byte (called descriptor in the parameter list at the end of the manual).

This function shouldn't be used in CANopen nets.

4.5 Temperature

sensors

Two temperature sensors are installed inside the BATCHCONTROL 5014C. The first one is

mounted on the BATCHCONTROL print board. This one measures the electronic temperature.

The information can be important during the CIP process or in hot filling application. If the

temperature is higher then 70°C the life time of the electronic components are reduced. An upper

and lower setpoint can be programmed. If one of this points are reached, an alarm message is

send via the CAN bus. Alternativly this information can be programmed for an output, which is

used as an alarm output.

The second sensor is mounted on the outside of the ceramic pipe. It has the same functionality as

the electronic temperature sensor. Since the temperature sensor doesn't have direct contact to the

liquid, the temperature measurement is delayed. The delay time depends on the temperature

gradient and the temperature difference between outside housing and liquid. The delay time can

be a few seconds.

Each sensor can be programmed for the following functions:

•

Without use (off)

•

Temperature value for the bus

•

Temparature alarm for the bus

• Customers

specific

programming

4.6 Flow

Sensor

The integrated flow sensor measures precisely the flow velocity. From this signal the device

generates the information for the internal electronic volume counter. Furthermore the flow values

and the counter are actualized every 20ms. It can be programmed for the following functions:

•

Without use (off)

•

Volume flow value for the bus

•

Totalized Volume value for the bus

4.7 An example for a filling process

The function of the device shall be represented at the example of a two-stage filling device. The

following order is used:

Output ‘1’ is for the low speed fluid valve. This valve is opened during the complete filling

time. The target volume is 1000ml.

Output ‘2’ is for the high speed fluid valve. This valve switch off 50ml before the target

4