Li i i i – KROHNE UFM 500 EN User Manual

Page 7

7

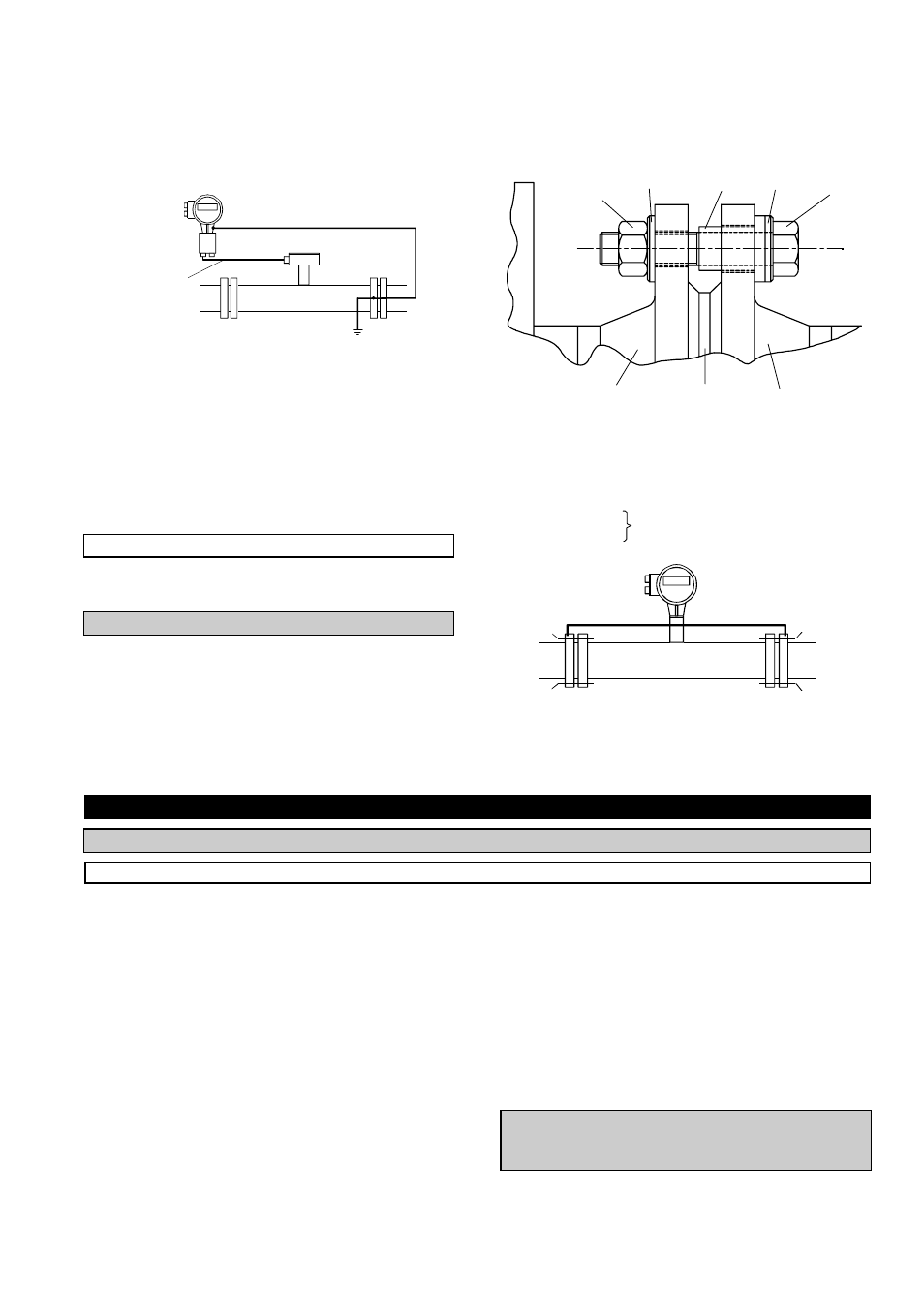

❹ Grounding with measuring ground M for separate

system flowmeters UFM 400 F / UFM 500 F

Do not connect up protective conductor PE incorporated

in the power supply cable, see sect. 2.2.2!

MR 02/04

Sensor cables, factory supplied, see sect.

2.2.3 for connection.

V

Connecting cable, cross-section

≥

4 mm

2

(AWG 10) Cu, equip with M6 cable lugs,

customer supplied.

M

Measuring ground; ground conductor,

cross-section

≥

4 mm

2

(AWG 10) Cu,

equip with M6 cable lugs, customer

supplied. Threaded hole in housing M4, 6

mm (0.24”) deep.

1.3.3

Grounding in hazardous areas

Special regulations are applicable, refer to sect. 6.1, and

the special “Ex” installation instructions.

1.4

Pipes with cathodic protection

•

Pipes with electric corrosion protection are generally

insulated inside and outside so that the fluid has no

conductive connection to ground. The primary head

must be insulated from the pipe. Note the following

when installing the flowmeter:

•

The pipe flanges must be connected to each other

using a copper cable (L), but must not be connected

to the primary head.

•

The bolts for the flange connections must be

insulated. Use sleeves and washers that made of

insulating material. Must be provided by customer.

1

Flange of

3 Pipe flange

6 Washer

Primary head

4 Bolt

7 Insulating

2

Gasket

5 Nut

sleeve

•

Grounding

I

Insulated bolts

L Copper cables

For grounding, be sure to read the instructions given in

sect. 1.3.1 and 1.3.2!

2.

Electrical connection

2.1

Compact flowmeters UFM 400 K, UFM 500 K

2.1.1

Installation location and cable diameter

Location

•

Do not expose the compact flowmeter to direct

sunlight. Install a sunshade if necessary.

•

Do not expose to intensive vibration. If necessary,

support the pipeline to the left and right of the

flowmeter.

Cable diameter

To conform to protection category requirements, observe

the following recommendations:

•

Cable diameter: 8 to 13 mm (0.31” to 0.51”).

•

Enlarge inside diameter by removing the appropriate

onion ring(s) from the seal of the screwed conduit

entry only if cables have extremely tight fit.

•

Fit blanking plug Pg 16 and apply sealant to unused

cable entries.

•

Do not kink cables directly at conduit entries.

•

Provide water drip point (U-bend in cable).

Conduit installation, general wiring consideration

•

When electrical codes require conduit, it must be

installed in such a manner that the meter terminal

compartment remains dry at all times.

•

Power and output wiring should be run in separate

conduit.

•

Use twisted pairs for output wiring.

Warning: Power wiring should utilize a grounded

neutral conductor to avoid possible shock hazard /

damage to component parts.

L

I

I

I

I

3

2

1

6

4

6

7

5

Not included with meter, must

be provided by customer.

MR 02

MR 04

V

M