Part a system installation and start-up – KROHNE UFM 500 EN User Manual

Page 5

5

Part A

System installation and start-up

1.

Installation in the pipeline

1.1

Preliminary information

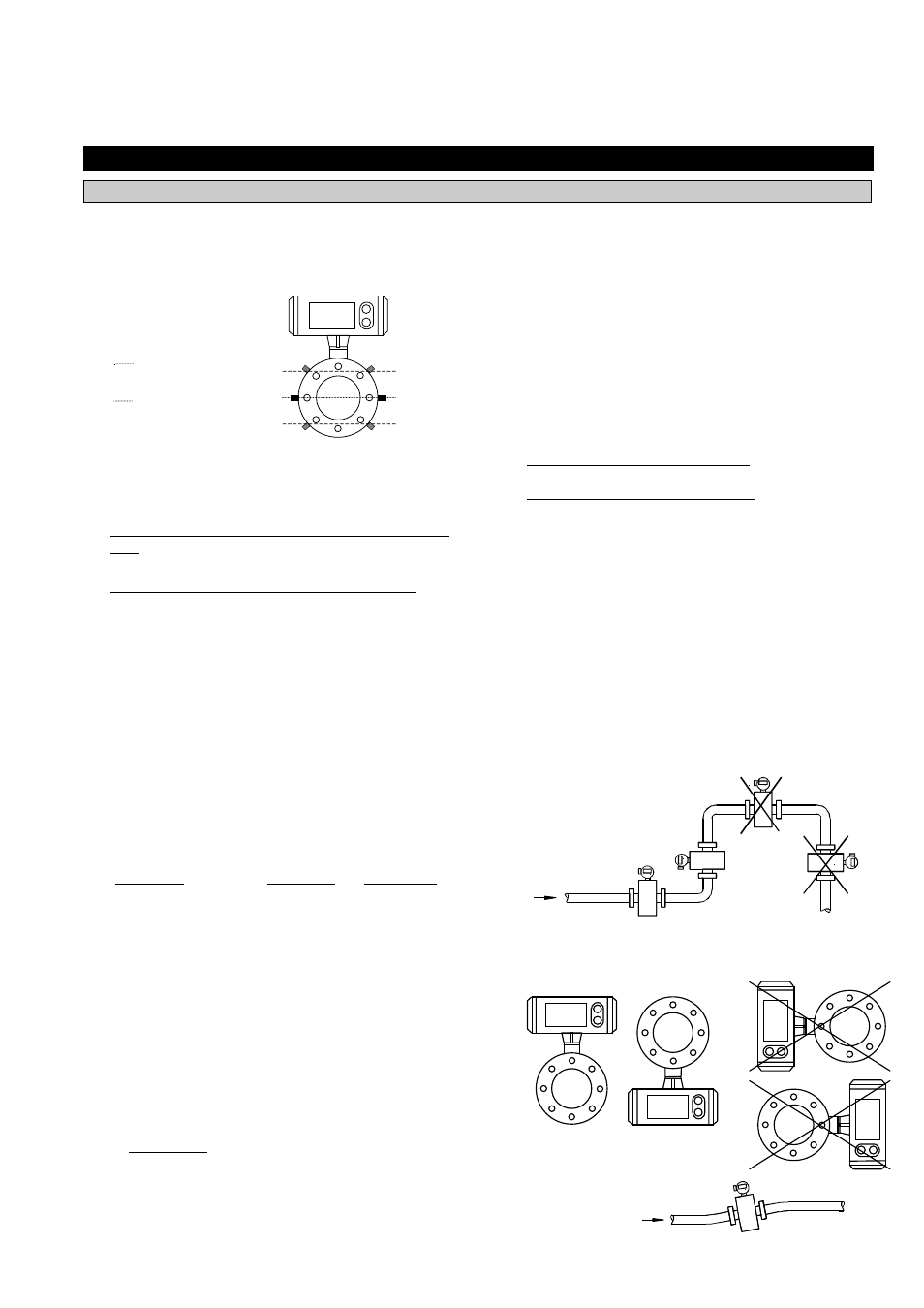

1. Location and position as required, but sensor axis

must be approximately horizontal if flowmeter is in-

stalled in slightly ascending or horizontal pipe runs.

2. Hard-to-reach locations

Where UFM 400 K and UFM 500 K compact flow-

meters have not been ordered and supplied in accor-

dance with Versions 1 to 10 (see sect. 8.6), the

configuration can be changed subsequently:

•

Turn the indicating circuit board through

±

90

°

or

180

°

to obtain horizontal positioning of the display

(see sect. 8.4)

•

Turn signal converter housing through

±

90

°

(see

sect. 8.5)

3. Measuring tube must be completely filled at all

times.

4. Flow direction +/-: note arrows on flowmeter and

also fct. 3.1.7 (refer to sections 4.3 and 5.4).

5. Bolts and nuts: to install make sure there is

sufficient room next to the pipe flanges.

6. Vibration: support the pipeline on both sides of the

flowmeter.

7. Large meter sizes, DN>200 (8”): use adapter pipes

to permit axial shifting of counter flanges to facilitate

installation.

8. Inlet and outlet sections

(DN = meter size)

Inlet section

single beam

double beam

−

Downstream of

pump

50

×

DN

15

×

DN

−

Downstream of fully

opened control valve

50

×

DN

10

×

DN

−

Downstream of 2

quarter bends on

different levels

40

×

DN

10

×

DN

−

Downstream of 2

quarter bends on one

level

25

×

DN

10

×

DN

−

Downstream of 1

quarter bend

20

×

DN

10

×

DN

−

Downstream of

reducer (

α

/2 = 7

°

)

15

×

DN

no additional

inlet section

−

Outlet section

5

×

DN

5

×

DN

9. Vortex or corkscrew flow: increase inlet and outlet

sections or install flow straighteners.

10. Zero setting is normally not necessary, but it can be

checked under flowing conditions as outlined in sect 7.2.

Shutoff valves should therefore be provided upstream

and/or downstream of the primary head unless the pipe

configuration already rules out the possibility of the

primary head being drained of fluid. (For zero check see

section 7.2).

11. Mixing different fluid products. Install the

flowmeter upstream of mixing point or at an

adequate distance downstream, minimum

distance 30x DN (DN = meter size), otherwise

output/display may be unsteady.

12. Ambient temperature:

product temperature

≤

60

°

C/140

°

F

all systems: -25 to +60

°

C/ -13 to +140

°

F

product temperature > 60

°

C/140

°

F

compact systems: -25 to +40

°

C/ -13 to +104

°

F

separate systems: -25 to +60

°

C/ -13 to +140

°

F

13. Pipeline along a wall: where possible, the distance

between pipe centerline and wall must be more than

0.5 m (1.6 ft) for the UFM 400 K and UFM 500 K

flowmeters. If less, first connect all cables to the

terminals in the terminal compartment (power supply

and outputs), and install an intermediate connection

box before installing flowmeter in pipeline.

14. Insulated pipeline: do not insulate UFM 400 K and

UFM 500 K compact flowmeters.

15. Suggestions for installation

To avoid measuring errors due to air inclusion, please

observe the following:

Sensor axis

(2 beams)

Sensor axis

(1 beam)

Highest point of pipe run

(Air bubbles that are collected in

the

measuring tube cause faulty

measurements).

Preferred

Locations

Downpipe

“ Zero“ flow

Velocity.

Lined drained.

Faulty

measurements

Open

discharge

.

Horizontal pipe run

Install in slightly ascending pipe section.

If not possible, ensure adequate

velocity

to prevent air, gas or vapor from

Horizontal and slightly ascending pipelines

Always install signal converter (and

terminal box) on the top or underside of

the pipe,