KROHNE UFM 500 EN User Manual

Page 34

34

7.

Functional checks

7.1

Test functions of UFC 500... signal converter fct.

2.1 to 2.5

7.1.1

Display test, fct. 2.1

•

Select function 2.1 as described in sect. 4.2 and 4.3.

•

Press

↵

key to start display test, duration approx. 30

seconds.

•

All segments in the 3 lines of the display are

activated sequentially.

•

The test can be terminated by pressing the

↵

key.

7.1.2

Test, current output I, fct. 2.2

•

A milliamp-meter must be connected to terminals

I/I+ for this test, see sect. 2.3.2 and 2.3.5, connections

diagram

c.

•

Select fct. 2.2 as described in sect. 4.2 and 4.3.

•

Select current value with

↑

key:

0 mA

2 mA

4 mA

10 mA

20 mA

22 mA

The milliamp-meter indicates the current value selected.

•

Press the

↵

key to terminate the test and display the

actual value again.

7.1.3

Test, frequency output F, fct. 2.3

•

An electronic totalizer (EC) must be connected to;

terminals B1 and B

⊥

for this test, see sect. 2.3.3 and

2.3.5, connections diagram

d.

•

Select function 2.3 as described in sect. 4.2 and 4.3.

•

Select frequency value with

↑

key:

1 Hz

10 Hz

100 Hz

1,000 Hz

The totalizer indicates the frequency value selected.

•

Press the

↵

key to terminate the test and display the

actual value again.

7.1.4

Test, status output S, fct. 2.4

An electronic indicator must be connected to terminals

B2 and B

⊥

for this test; see sect. 2.3.4 and 2.3.5,

connection diagram

d. Select fct. 2.4 as described in

sect. 4.2 and 4.3. Select the status with

↑

key:

•

STATUS OFF or

•

STATUS ON.

The indicator indicates the selected status. Press the

↵

-

key to terminate the test and display the actual value

again.

7.1.5

Test, microprocessor, fct. 2.5

•

Select function 2.5 as described in sect. 4.2 and 4.3.

•

Press the

→

key, displayed: TESTING.

•

Approx. 2 seconds test duration, display:

either NO ERROR = signal converter in order

or

ERROR = signal converter possibly defective.

Corrective action: Switch power source briefly off and

repeat test. If error message is still

shown, replace electronic unit, see

sect. 8.1.

7.2

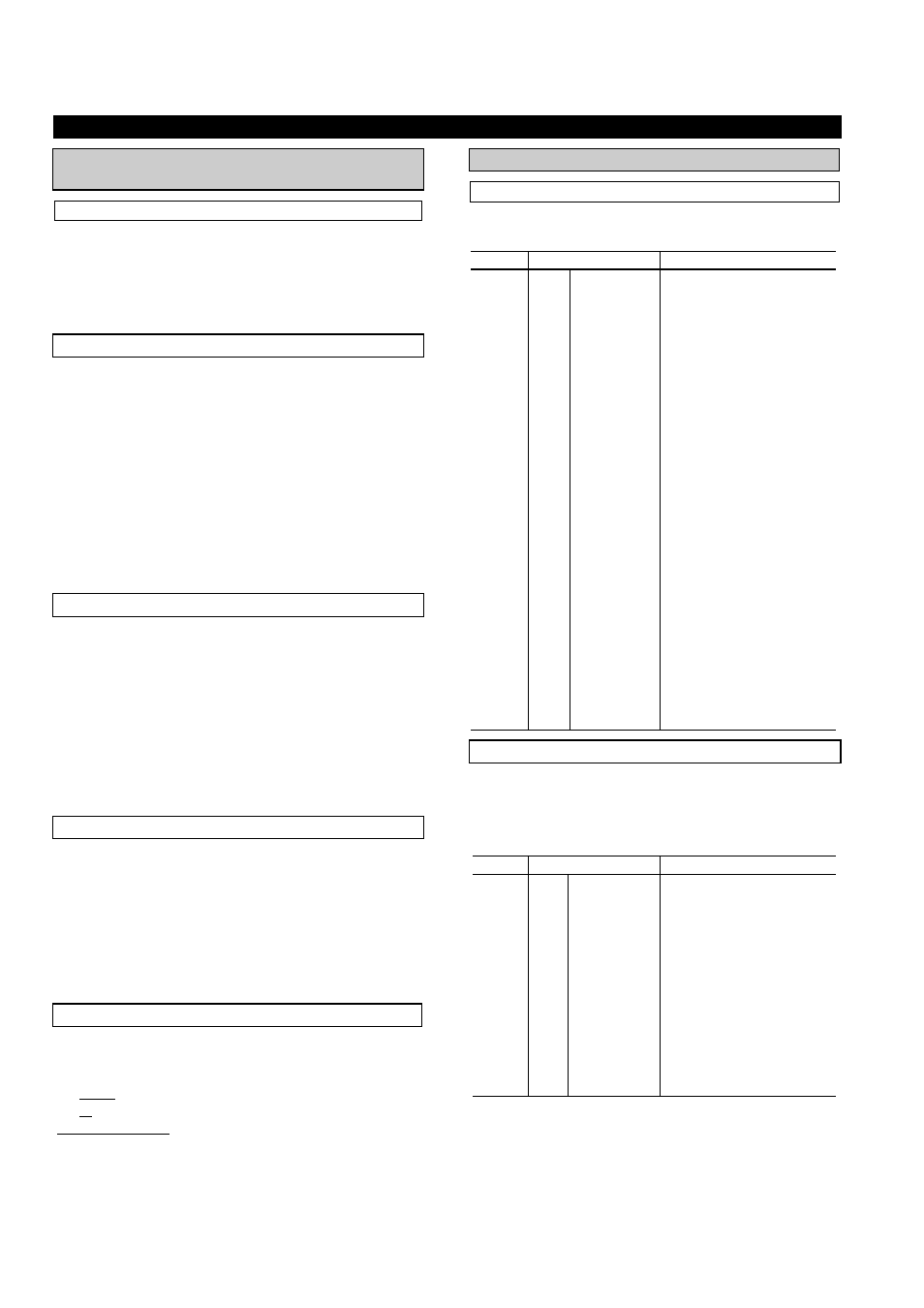

Zero check with UFC 500 ... signal converter

7.2.1

Measure zero value

Set “zero” flow in the pipeline, but make sure that the

primary head is completely filled with fluid.

Key

D i s p l a y

Description

→

1.0

OPERATION

If Entry Code 1 is selected

see fct. 3.6.2, set 9-keystroke

Code 1 now.

→

1.1.0

BASIS.PARAM

.

→

1.1.1

FULL SCALE

3 (2)

∗

→

1.1.4

ZERO SET.

→

VALUE.

MEASU

If FIXED.VALUE appears

here, set VALUE. MEASU

(measured value) with

↑

key.

↵

CALIB. NO

↑

CALIB. YES

↵

0.0

PERCENT

Zero measurement in

progress (approx. 20 seconds

duration).

Display: actual flowrate in

percent of full-scale range,

max. deviation

±

0.2%; if

greater, check whether

flowrate is actually “zero”.

STORE NO

If new value is not accepted,

press

↵

key 5 times = return

to measuring mode.

↑

STORE YES

↵

1.1.4

ZERO SET.

Zero set to new value.

4

∗

↵

........ ..................

Measuring mode with new

zero value.

7.2.2

Fixed zero value

If “zero” flow in the pipeline is not adjustable, zero can

be set to a specified fixed value (factory setting).

NOTE: Additional measuring error possible in this case,

to avoid it, see sect. 7.2.1 “measure zero value”.

Key

Display

Description

→

1.0

OPERATION

If Entry Code 1 is selected see

fct. 3.6.2; set 9-keystroke Code

1 now.

→

1.1.0 BASISPARAM.

→

1.1.1 FULL SCALE

3 (2)

∗

↑

1.1.4 ZERO SET.

→

FIXED.VALUE If

VALUE. MEASU

(measured value) appears

here, set

FIXED.VALUE with

↑

key.

↵

1.1.4 ZERO SET.

Zero set to fixed value.

4

∗

↵

......... ...................... Measuring mode with fixed

zero value.