KROHNE UFM 500 EN User Manual

Page 6

6

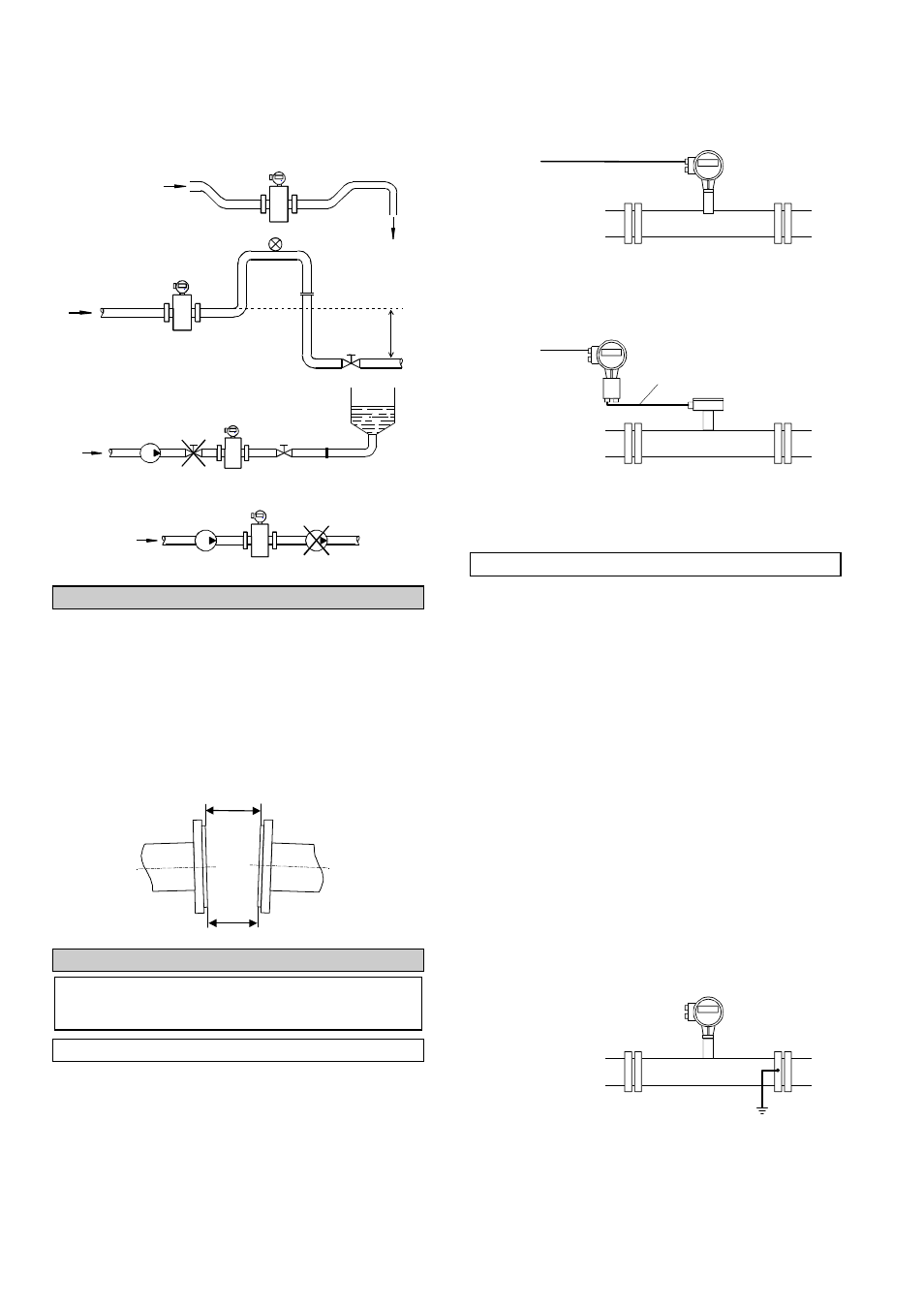

(Suggestions for installation continued):

1.2

Pipe flanges

Flange spacing

Refer to dimensional drawings (section 10.4 and 10.5),

in addition allow for thickness of gaskets.

Position of flanges

•

Install flowmeter in line with pipe axis.

•

Pipe flange faces must be parallel to each other, max.

permissible deviation: L

max

- L

min

≤

0.5 mm (0.02”).

1.3

Grounding

Warning

Instrument should be properly grounded to avoid

personnel shock hazard!

1.3.1

Standard grounding

The flowmeter must normally be grounded via the

protective conductor PE incorporated in the power

supply cable. Connect the protective conductor to the

separate U-clamp terminal in the terminal compartment

of the signal converter. See sect. 2.1.2 for the compact

flowmeters, and sect. 2.2.2 for the separate systems.

❶ Standard grounding of compact flowmeters UFM

400 K / 500 K

PE

Protective conductor incorporated in the power

supply cable, see sect. 2.1.2.

❷ Standard grounding of separate system flowmeters

UFM 400 F / 500 F

PE

Protective conductor incorporated in power

supply cable, see sect. 2.2.2

MR 02/04

Sensor cables, factory supplied, see sect.

2.2.3 for connection.

1.3.2

Grounding with measuring ground M

This type of grounding must be employed if at least one

of the two following operating conditions occurs:

A If large potential differences occur between

protective ground and electric furnaces or electrolysis

plants.

B If a protective ground conductor is not provided,

e.g. for DC voltage operation.

Observe the following when grounding with separate

measuring ground M:

Do not connect up the protective ground conductor PE in

the terminal box if measuring ground M is connected.

If the AC supply voltage exceeds 50 V

rms

, then the

measuring ground simultaneously acts as the protective

ground conductor (combined protective/functional

ground). Refer to appropriate national codes for specific

requirements for this type of installation, which may

require the addition of a ground fault detection circuit

interrupter.

❸ Grounding with measuring ground M for compact

flowmeters UFM 400 K / 500 K

Do not connect up protective conductor PE incorporated

in the power supply cable, see sect. 2.1.2!

M

Measuring ground; ground conductor, cross-section

≥

4 mm

2

(AWG 10) Cu with M6 cable lugs, customer

supplied. Threaded hole in housing M4 by 6 mm.

Pump

Never install flowmeter on

pump suction side (cavitation,

Long pipeline

Always install control and shutoff

valves

Open feed or

discharge

Install meter in low

Open

discharg

Downpipe over 5 m (16 ft) length

Install air valve

downstream of

flowmeter (cavitation).

> 5 m

(16 ft)

PE

MR 02

MR 04

L

max

L

min

PE

M