KROHNE UFM 610P EN User Manual

Page 49

49

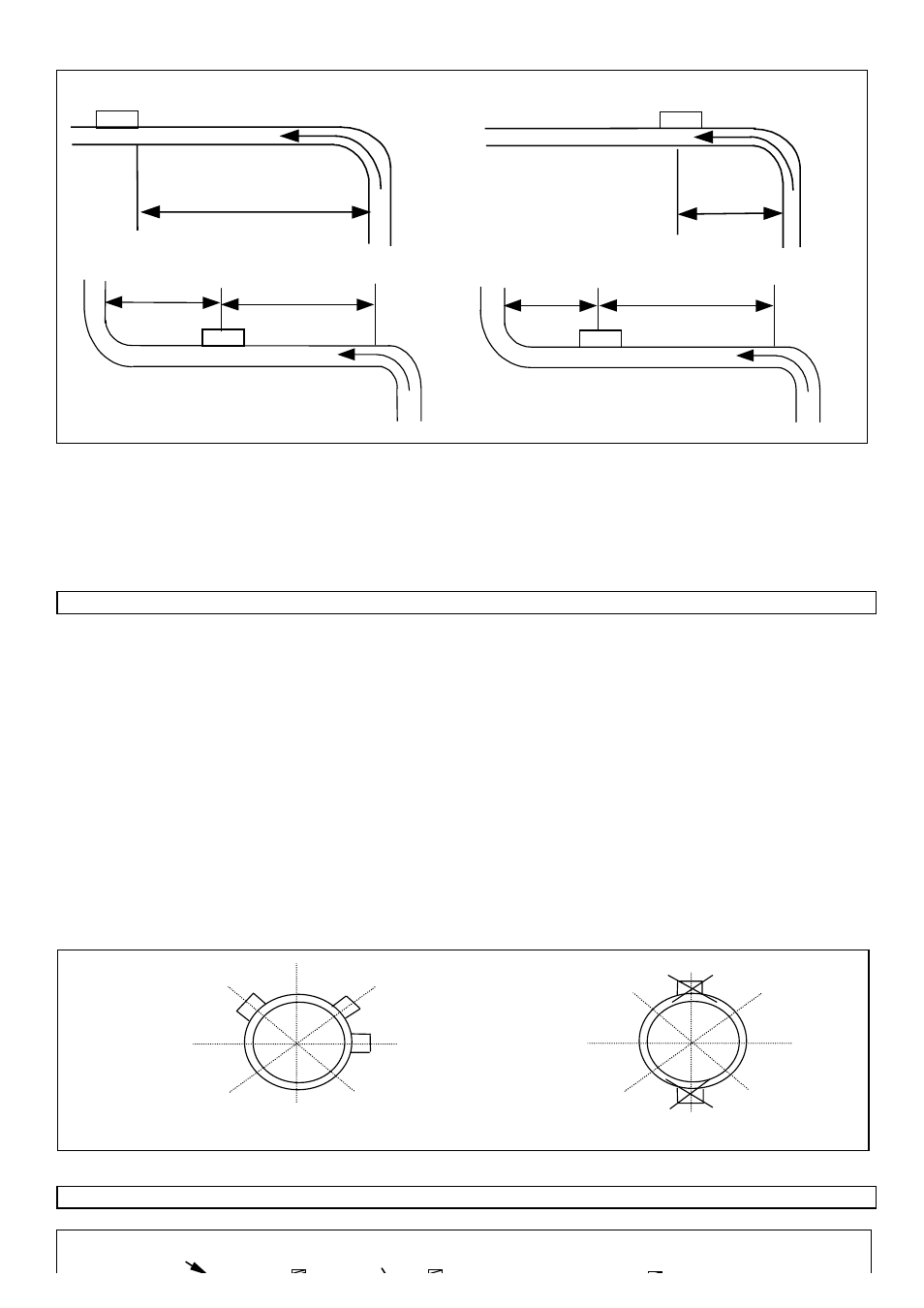

The minimum length of upstream straight pipe is 20 Diameters and 10 Diameters downstream which ensures that accurate

results will be achieved. Flow measurements can be made on shorter lengths of straight pipe down to 10 Diameters upstream

and 5 Diameters downstream, but when the transducers are sighted this close to any obstruction errors can be considerable.

It is not possible to predict the amount of error as this depends entirely upon the type of obstruction and the configuration of the

pipework. The message therefore is clear: Do not expect to obtain accurate results if the transducers are positioned closer than

allowed to any obstruction that distorts the uniformity of the flow profile.

6.2

Mounting the transducers

It will be impossible to achieve the accuracy of measurement specified for the UFM 610 P if the transducers are not clamped to

the pipe correctly and if the data - O.D., Wall Thickness, Pipe Material and Product - are not accurate.

Apart from the correct positioning and alignment of the transducers, of equal importance is the condition of the pipe surface in

the area under each of the transducers.

An uneven surface that prevents the transducers from sitting flat on the surface of the pipe can cause Signal Level and Zero

Offset problems. The following procedure is offered as a guide to good practice with respect to positioning and mounting the

transducers.

1.

Select the site following the rules laid down as above - Transducer Positioning.

2.

Inspect the surface of the pipe to ensure it is free from rust or is not uneven for any reason. Transducers can be mounted

directly on painted surfaces as long as the surface is smooth and that the underlying metal surface is free from rust bubbles.

On bitumen or rubber coated pipes the coating must be removed in the area under the transducers, as it is preferable that the

transducers are mounted directly on to the base metal.

3.

Transducers can be mounted on both Vertical and Horizontal Pipe Runs.

4.

Apply Interface couplant to the face of the transducers. The amount of couplant used is extremely important particularly on

pipes of less than 89mm bore.

6.2.1

Transducer set "A"

> 20 D

FLOW

CORRECT

FLOW

10 D

20D

INCORRECT

< 20 D

FLOW

FLOW

5 D

20D

Figure18

TOP

BOTTOM

HORIZONTAL

TOP

BOTTOM

CORRECT

INCORRECT

Figure 19

moveable sensor block

fixed sensor block