KROHNE UFM 610P EN User Manual

Page 48

48

When ultrasound is transmitted from Transducer “X” to Transducer “Y” (REFLEX MODE) or Transducer “X” to “Z”

(DIAGONAL MODE) the speed at which the sound travels through the liquid is accelerated slightly by the velocity of the

liquid. If sound is transmitted in the opposite direction from “Y” to “X” or “Z” to “X”, it is decelerated because it is travelling

against the flow of the liquid. The difference in time taken to travel the same distance but in opposite directions is directly

proportional to the flow velocity of the liquid.

Having measured the flow velocity and knowing the pipe cross-sectional area, the volumetric flow can be easily calculated. All

of the calculations required to first determine the correct alignment of the transducers and subsequently compute the actual flow

are carried out by the microprocessor. To measure flow, it is first necessary to obtain detailed information about each

application, which is then programmed into the processor via the Key Pad. This information must be accurate otherwise flow

measurement errors will occur.

Further, having calculated the precise position at which the transducers must be clamped onto the pipe wall, it is equally

important to align and separate the transducers accurately with respect to one another, as failing to do so will again cause errors

in measurement.

Finally to ensure accurate flow measurement it is imperative that the liquid is flowing uniformly within the pipe and that the

flow profile has not been distorted by any upstream or downstream obstructions. To obtain the best results from the UFM 610 P

it is absolutely necessary that the following rules for positioning the transducers are adhered to and that the condition of the

liquid and the pipe wall are suitable to allow transmission of the sound along its predetermined path.

6.1

Transducer

As the transducers for the UFM 610 P are clamped to the outside surface of the pipe, the meter has no way of determining

exactly what is happening to the liquid. The assumption therefore has to be made that the liquid is flowing uniformly along the

pipe either under fully turbulent conditions or under laminar flow conditions. Further it is assumed that the flow velocity profile

is uniform for 360

°

around the pipe axis.

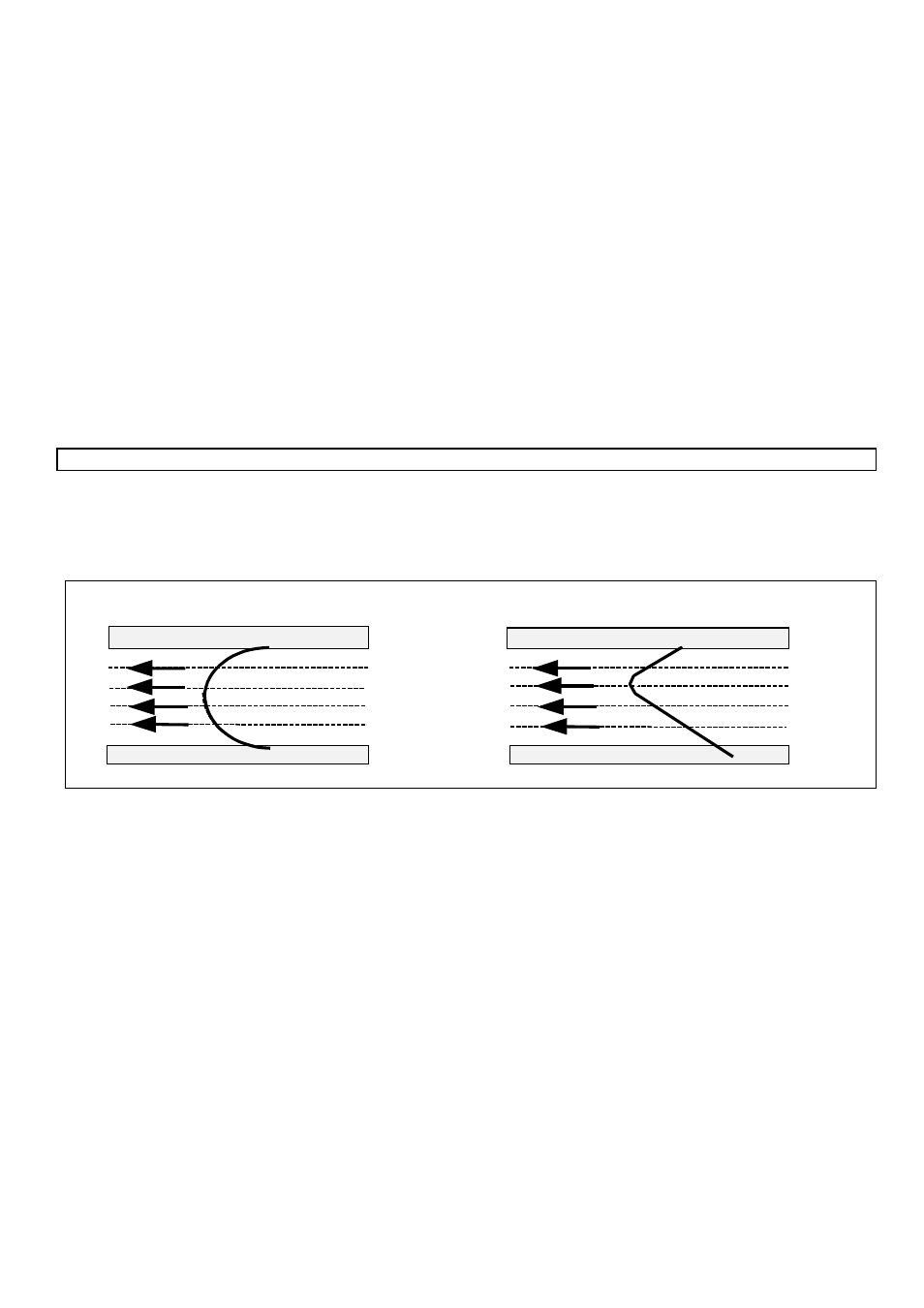

The difference between (a) and (b) is that the Mean Velocity of the flow across the pipe is different and because the UFM 610 P

expects a uniform flow as in (a), the distorted flow as in (b) will give measurement errors which cannot be predicted or

compensated for. Flow profile distortions result from upstream disturbances such as bends, tees, valves, pumps and other similar

obstructions. To ensure a uniform profile the transducers must be mounted far enough away from any cause of distortion such

that it no longer has an effect.

a

b

Figure 17 - shows an uniform profile as compared to a distorted profile.