Section 4 - calibration, 1 general, Table 4-1. calibration summary (continued) – KEPCO BOP 1KW-MG Operator Manual, Firmware Ver.2.48 to 3.04 User Manual

Page 129: General -1, Calibration summary -1

BOP-1K 101509

4-1

SECTION 4 - CALIBRATION

4.1

GENERAL

This section contains the calibration instructions for the Power Supply. It is recommended that

the user be familiar with Local Mode operation (PAR.3.2) before calibrating the unit.

A full calibration consist of a voltage calibration and a current calibration. Both voltage and cur-

rent calibrations consist of zero, max and min, and protection limit calibration. In addition, the

control signals required for series and parallel operation of multiple units are also calibrated. It is

recommended that the unit be recalibrated annually.

In order to enter the calibration mode the correct password may be required (see PAR. 3.2.4.4).

If the password has been lost, call the factory and a special password will be provided. During

the calibration, new calibration data is computed which is then stored in the nonvolatile memory.

Calibration of the BOP is performed in one of three ways: locally using the front panel keys

(PAR. 4.4), remotely by sending commands through either the GPIB or RS 232 bus (PAR. 4.3),

or remotely using the graphical interface supplied with the instrument driver available at

www.kepcopower.com/drivers.htm (PAR. 4.4.3). This VISA compliant driver works with many

GPIB cards from suppliers like National Instruments and Hewlett-Packard. These three ways

cannot be combined. Separate calibration procedures are provided for units connected in series

or parallel.

NOTE: During calibration, various circuits of the BOP are verified. If an error occurs during the

verification process, the unit will beep and an error 24(x), Hardware, (see PAR. B.130)

will be placed in the error queue.

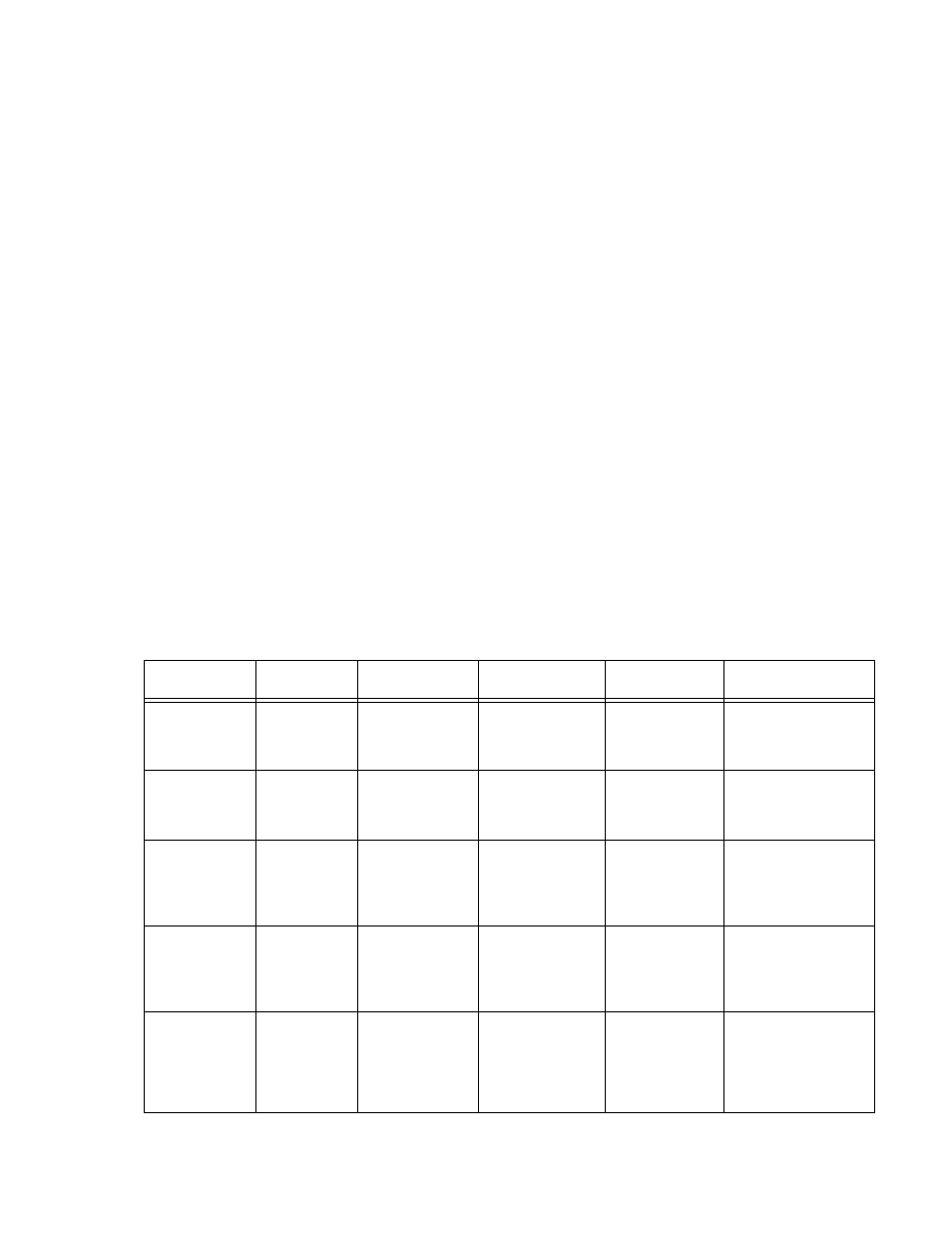

TABLE 4-1. CALIBRATION SUMMARY

Type

Step

Reference Type

and Value

Monitored

Parameter

Output Conditions

Notes

VOLTAGE

INTERNAL

1. ZERO

2. POSITIVE

3. NEGATIVE

Internal

Output Voltage

1. 0.0v

2. +Voltage FS

3. –Voltage FS

NO LOAD

AUTOMATIC VM

1. DVM between OUT S

and COM S.

2. Adjust for zero, posi-

tive and negative FS.

VOLTAGE

PROTECTION

1. POSITIVE

2. NEGATIVE

Internal

Output Voltage

1. +Voltage FS

2. –Voltage FS

NO LOAD

AUTOMATIC CM

1. DVM between OUT S

and COM S.

2. Adjust for positive

and negative FS.

VOLTAGE

EXTERNAL

1. ZERO

2. POSITIVE

External:

1. 0.0V

2. +10.0V

(Analog I/O Port,

pin 11 ref to pin 4)

Output Voltage

1. 0.0v

2. –Voltage FS

NO LOAD

AUTOMATIC VM

1. DVM between OUT S

and COM S.

2. Adjust for zero, posi-

tive FS.

VOLTAGE

GAIN

1. ZERO

2. POSITIVE

External:

1. 0.0V

2. +10.0V

(Analog I/O Port

pin 11 ref to 4)

Output Voltage:

1. 0.0V

2. 0.0V

No Load

Automatic VM

1. DVM between OUT S

and COM S

2. Adjust for zero

(both Zero and Posi-

tive).

EXTERNAL

CONTROLS,

SERIES

1. ZERO

2. POSITIVE

External:

1. 0.0V

2. -10.0V

(Par/Ser CTRL-IN

Port, pin 8 ref to 1)

Output Voltage:

1. 0.0V

2. +10.0V

No Load

Automatic VM

1. DVM between OUT S

and COM S

2. Adjust for zero,

+10.0V

3. Calibrate unit for

Slave in Series