Edwards Signaling INT-22_5R1-24 User Manual

Edwards Signaling Safety

4

Operating Instruction

INT-22.5R1-24

Base Device for Emergency Stop and Safety Gate

Applications

• Basic device to EN 60204-1 and EN 954 - 1

• Safety category 4 to EN954-1

• Stop category 0 to EN 60204-1

• Manual or automatic start

• Cross monitoring

• Feedback circuit for monitoring external contactors

• 3 enabling current paths

• Equivalent and non-equivalent activation

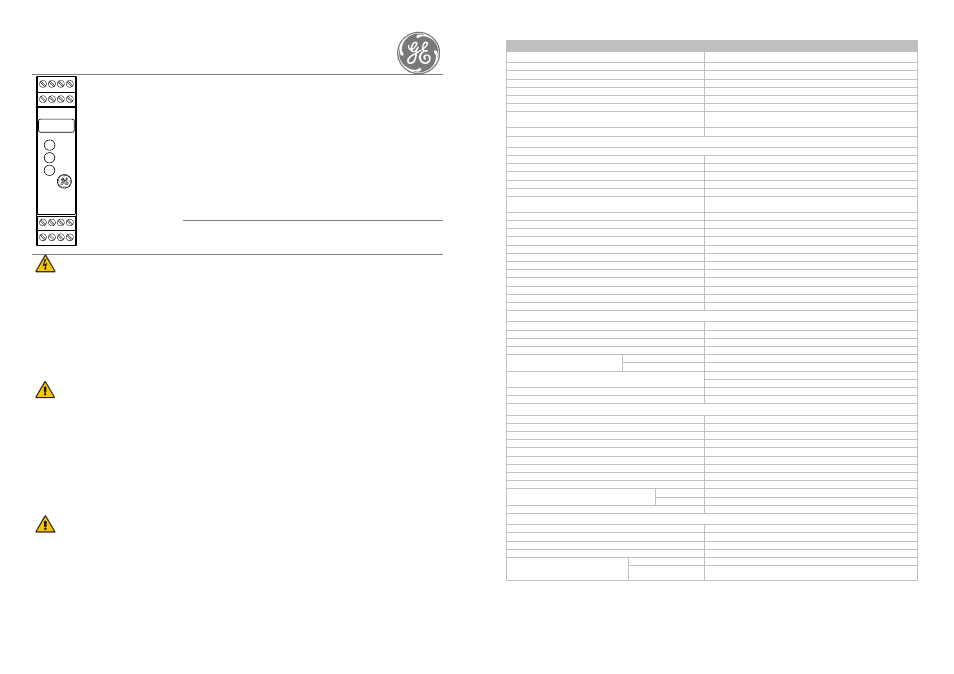

K2

A1

INT-22.5R1-24

S23

13

S24

23

S33

33

S34

S13

A2

S14

14

S35

24

S22

34

SUPPLY

K1

Front View

SUPPLY LED green Power Supply

K1

LED green Relay K1

K2

LED green Relay K2

Safety Instructions

Only trained professional electricians may

install, startup, modify, and retrofit this

equipment! Disconnect the device / system

from all power sources prior to starting any

work! If installation or system errors occur,

line voltage may be present at the control

circuit in devices without DC isolation!

Observe all electrical safety regulations

issued by the appropriate technical authorities

or the trade association. The safety function

can be lost if the device is not used for the

intended purpose. Opening the housing or

any other manipulation will void the warranty.

Caution!

Perform the following precautionary steps

prior to installation, assembly, or disassembly:

1. Disconnect supply voltage to the

equipment / system prior to starting any

work!

2. Lockout/tag the equipment / system to

prevent accidental activation!

3. Confirm

that

no

voltage is present!

4. Ground the phases and short to ground!

5. Protect against adjacent live

components using guards and barriers!

6. The devices must be installed in a

cabinet with a protection class of at least

IP 54.

Caution!

Limited contact protection! Protection type

according to DIN EN 60529.

Housing/terminals: IP 40/ IP 20.

Finger-proof acc. to VDE 0660 Part 514.

Description of Device and Function

This device is a two-channel safety switching device with self-monitoring on each ON-OFF cycle.

It conforms to EN 60204-1 and is equipped with positively driven relays. It is intended for

monitoring connected switching elements on separating safety devices and generating a safety-

oriented output signal (enable). Depending on the design, separating safety devices may include

protective screens, safety doors, enclosures, covers, screens, etc.

Basic function: After supply voltage has been connected to terminals A1/A2 and the safety

inputs closed, operating the reset button closes the enabling current paths (manual start). When

the safety inputs are opened the enabling current paths will open.

Operating modes / system functions

• Two-channel activation The device uses two-channel activation. With equivalent activation

safety channel CH1 is connected via positive potential, safety channel CH2 via negative

potential. With non-equivalent activation both safety channels are connected to positive

potential.

• Cross monitoring With equivalent activation cross monitoring is achieved by means of the

short-circuit principle; with non-equivalent activation it is achieved through functional

diversity.

• Manual start When the safety inputs are closed, a button is used to close reset input S34

and then open it again (triggering with falling edge) or to close reset input S35 (triggering

with rising edge).

• Automatic start Reset input S35 is connected to S33/S14. The device starts with the rising

edge of the signal on safety input S14.

• Starting lockout After supply voltage has been connected and the safety inputs closed, the

enabling paths will not close. Starting is only possible after the reset button has been

operated. For starting lockout the reset inputs have to be activated with the button, as in

manual start mode.

• Restarting lockout No restart after the safety inputs have been opened and closed.

Restarting is only possible after the reset button has been operated. For restarting lockout

the reset inputs have to be activated with the button, as in manual start mode.

• Synchro-check Synchro-check is only possible in automatic start mode (bridge S33/S14 -

S35). After safety channel CH1, safety channel CH2 must close (S24) or open (S22) within

the synchronous time t

S

. If CH2 closes or opens before CH1, the synchronous time t

S

=

∞.

Please observe instructions from safety authorities.

9

Caractéristiques techniques

Circuit d’alimentation

Tension nominale U

N

AC/DC 24 V, AC 115 – 120 V, AC 230 V

Puissance assignée DC

2,0 W

Puissance assignée AC

2,6 W / 3,2 VA

Ondulation résiduelle U

SS

2,4

V

Fréquence nominale

50 ... 60 Hz

Plage de la tension de service

0,85 ... 1,1 x U

N

Fusible pour alimentation circuit de commande

résistant aux courts-circuits (appareils DC: résistance PTC / Appareils AC:

transformateur résistant aux courts-circuits)

Circuit de commande

Sorties S13, S23

Tension de sortie nominale S13, S23

DC 22 V

Tension à vide appareil AC

< 40 V

Courant de sortie

100 mA

Résistant aux courts-circuits / limitation de courant

oui / non

Entrées S14/S33, S22, S24, S34, S35

Plage de la tension d’entrée (pour alimentation externe, uniquement

pour les appareils DC)

DC 17,4 V à DC 26,4 V

Courant nominal / courant de pointe S14/S33, S22, S24

40 mA / 100 mA

Courant nominal / courant de pointe S34, S35

5 mA / 50 mA

Temps

Temps d’impulsion de test admis t

TP

/ fréquence de test

≤ 1000 µs / ≤ 10 s

-1

Temps de réponse t

A1

S34

20 ms à 40 ms

Temps de réponse t

A2

S35

200 ms à 600 ms

Temps de réponse t

A3

100 ms à 400 ms

Durée mini de maintien t

M

S34, S35

> 80 ms

Temps de synchronisation t

S

CH1 avant CH2

env. 200 ms

Temps de réarmement t

W

≥ 100 ms

Temps de relâchement t

R

K1, K2

< 25 ms

Circuit de sortie

Contacts de sortie

Equipement des contacts

3 contacts de travail, à guidage forcé

Tension nominale de coupure U

n

AC 230 V / DC 300 V

Courant continu max. I

n

pour chaque contact

6 A

AC/DC 24 V

12 A

Courant total max. de tous les contacts

AC 115 - 120 V, AC 230 V 8 A

AC-15 : Ue 230 V, Ie 4 A (360 h

-1

) DC-13 : Ue 24 V, Ie 4 A (360 h

-1

)

Catégorie d’utilisation selon IEC 947-5-1

AC-15 : Ue 230 V, Ie 3 A (3600 h

-1

) DC-13 : Ue 24 V, Ie 2,5 A (3600 h

-1

)

Durée de vie mécanique (commutations)

10x10

6

Caractéristiques générales

Entrefers et lignes de fuite entre les circuits électriques EN

60947-1:12.99

Catégorie de surtension

III

Surtension transitoire assignée

4 kV

Degré de pollution de l’appareil : à l’intérieur / à l’extérieur

2 / 3

Tension assignée

300 V

Tension alternative d’essai

2 kV

Classe de protection selon DIN VDE 0470 partie 1: Boîtier / bornes

IP 40 / IP 20

Température ambiante / de stockage

-25 ... +55 °C / -25 ... +75 °C

Classe d’application climatique

H V G selon DIN 40040 : 04:87

Appareil DC

0,21 kg

Poids

Appareil AC

0,25 kg

Données sur les bornes et les connexions

Unifilaire (fil rigide) ou fils de faible diamètre (multibrins)

1 x 0,14 mm² à 2,5 mm² 2 x 0,14 mm² à 0,75 mm²

Longueur de dénudation

max. 8 mm

Fil à faible diamètre (multibrins) avec embout selon DIN 46228

1 x 0,25 mm² à 2,5 mm² 2 x 0,25 mm² à 0,5 mm²

Couple de serrage max.

0,5 à 0,6 Nm

Sections de connexion

AWG 18-16 utiliser uniquement conducteurs en Cu

Pour homologations UL (Underwriters

Listing Loboratories) et CSA (Canadian

Standards Associations)

Couple de serrage max. 0,79 in-lbs