Caution, Warning – Edwards Signaling 48 Series User Manual

Page 2

P-047550-1448 ISSUE 10

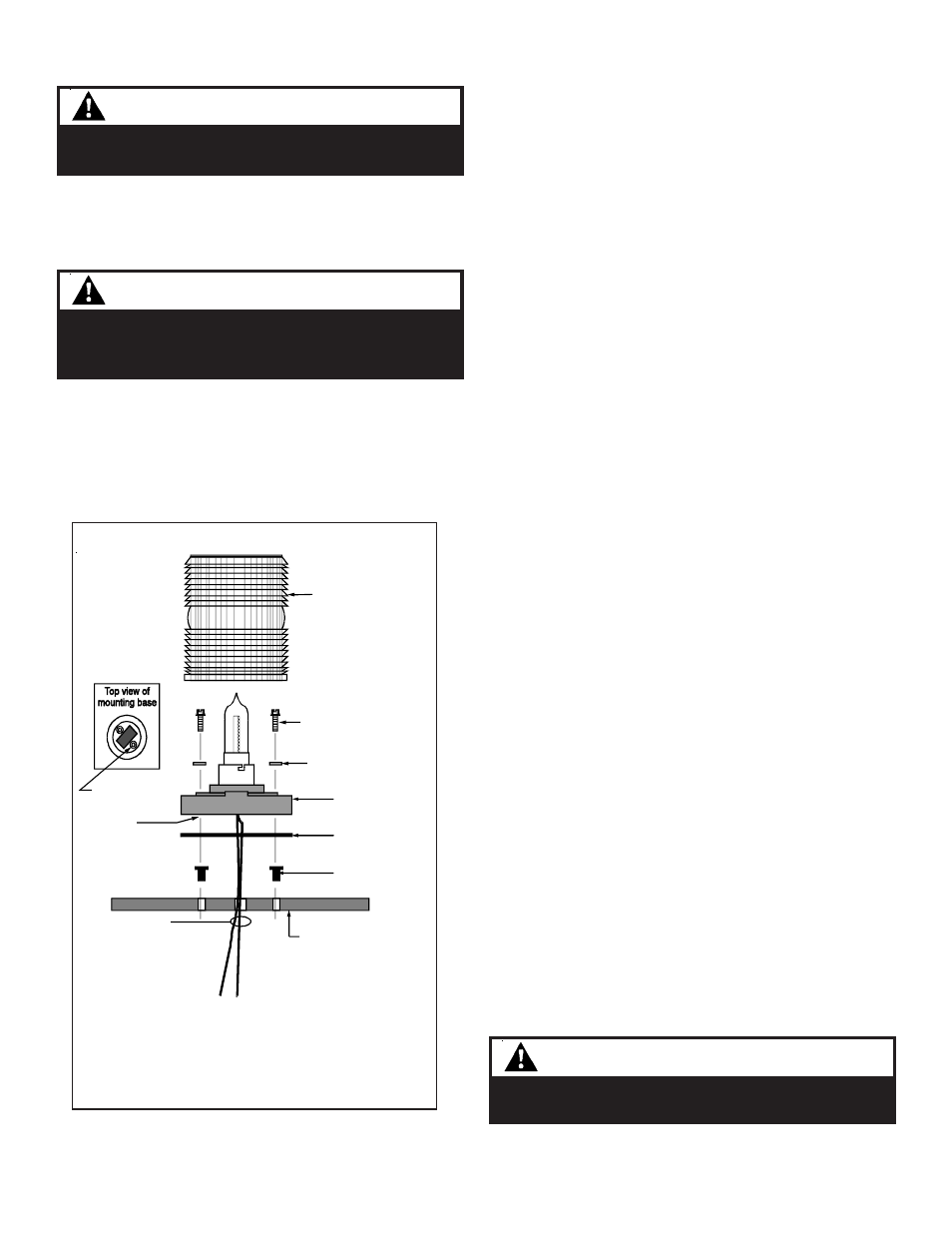

Figure 2. Direct Surface Mounting of the 48 Series

Signals

NOTE: Enclose wiring within an approved raceway

interconnecting the appliance and junction

box in accordance with governing codes,

standards and regulations.

Installation

Direct Surface Mounting (Indoor Only) - Figure 2

NOTE: AC signals may be direct surface mounted but are not

supplied with a direct surface mounting kit. The

installer should use suitable hardware appropriate for

the installation.

1.

Insert a small flat blade screwdriver between the locking

mechanism and the lens. Gently push down and then pry up,

unseating the lens. Pull the lens up and off of the signal

mounting base, being careful not to damage the lamp.

2.

Remove the two knockouts for mounting screws from the

signal base. Place the 3-3/4" (95mm) mounting gasket

provided in the direct surface mounting kit (DC models only)

on the mounting surface and mark the center of the three

holes in the gasket on the mounting surface. Remove the

gasket and drill a 3/8" (10mm) hole at each of the marked

positions.

3.

Install the two rubber expansion plugs provided in the

hardware kit (DC models only) into the two outer holes in

the mounting surface.

4.

Route the wire leads from the signal base through the center

hole in both the mounting gasket and surface. The wiring

should be run through an approved raceway or conduit

connected between the bottom of the signal base and an

approved junction box (not supplied). Bring wire leads into

the junction box. Refer to the signal's label for voltage rating.

5.

Align the outer holes in the mounting gasket with the holes

in the surface. Insert two screws with lockwashers through

the two outer holes in the signal base and align the screws

with the rubber expansion plugs as shown in Figure 2. Press

the signal base firmly against the mounting surface and tighten

the screws.

6.

Connect the field wiring to the signal wire leads as described

in the Wiring Section.

Wiring

1.

For AC models, use wire nuts (not supplied) and connect the

signal's black and white wire leads to the power source wires.

Polarity is not important.

2.

For DC models, connect the signal's red wire to the positive

power source wire and connect the signal's black wire to the

negative power source using appropriate connectors (not

supplied). Polarity must be observed.

Troubleshooting

If the signal light fails to operate, make sure there is power to the

signal. If there is power and the light still fails to operate, replace

the lamp as directed in the "lamp replacement" section.

Maintenance

Cleaning

To field wiring

One of two

knockouts for

direct surface

mounting

Lens

(2) Mounting

screws (supplied with

DC models)

(2) Lockwashers (supplied

with DC models)

Mounting base

and lamp

support plate

Mounting gasket

(supplied with DC

models)

(2) Rubber expansion

plugs (supplied with

DC models)

Mounting surface

Enclose in

Raceway

CAUTION

To prevent damage to the lens, do not use abrasive

materials or cleaners.

WARNING

To prevent electrical shock, ensure that power is

disconnected before installing the signals.

WARNING

To prevent leakage and a potential shock hazard,

when mounting outdoors the signal must be

installed with the lens or dome facing directly up.

Install in accordance with the latest edition of the National Elec-

trical Code and local regulations. Install the signals using one of

the following applicable mounting procedures.

Conduit Mounting (Indoor or Outdoor) - Figure 1

1.

Route the signal's wire leads through 1/2" (13mm) NPT

conduit (not supplied) and thread the conduit into the signal

mounting base.

2.

Connect the field wiring to the signal wire leads as described

in the Wiring Section.

Periodically clean the Adaptabeacon lens surface with a soft cloth

or sponge and water or a mild detergent solution to maintain op-