Return air duct sampling method – Edwards Signaling ReadySet User Manual

Page 25

Chapter 3: Installation and configuration

ReadySET Aspirating Smoke Detection System Installers Handbook

17

Return air duct sampling method

Duct sampling generally is the most cost-effective method of air sampling because the

pipe runs are minimal and a single detector may be used to cover a larger area. The

speed of response of the detector to smoke is given by the exchange rate in the rooms

ventilated by the duct ventilation system. This tends to be rapid, giving early warning of

any smoke present. This type of sampling is particularly suited to aspirated smoke

detection, since the smoke content in the air will tend to be diluted to a level below that

of point type detectors. Also, the relatively high airflow in the duct reduces the

effectiveness of point-detection devices.

The duct sampling method does have one major disadvantage. If the ventilation

becomes inoperative, the air-flow through the duct system ceases and the smoke-

detection system becomes ineffective.

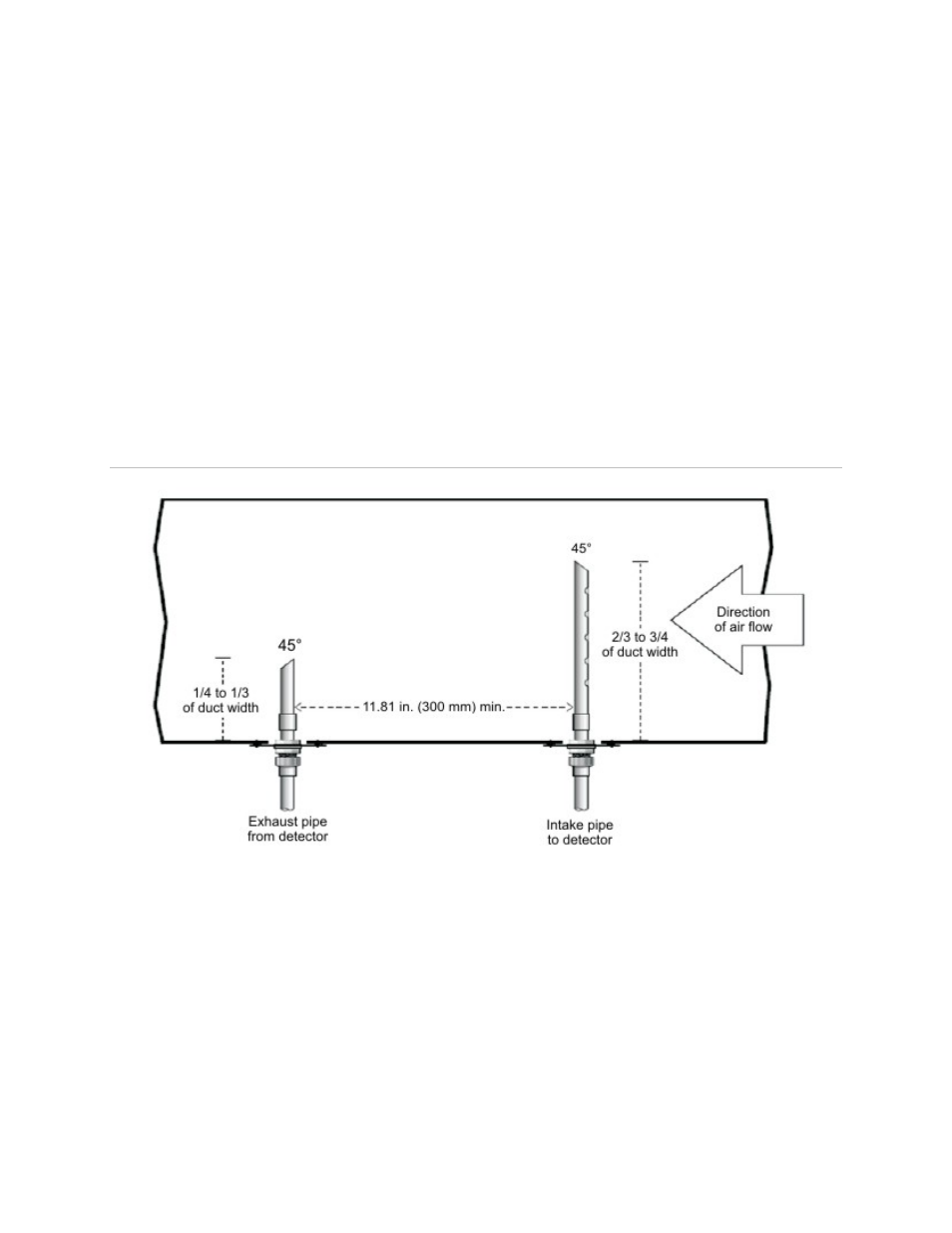

Figure 7: Return air duct sampling

Figure 7 above shows a typical sampling pipe arrangement for an air duct. The right

pipe is the sampling pipe and the holes on it are drilled 4 inches apart and face into the

oncoming air stream. The left pipe exhausts air from the detector.

The detector is UL 268A and ULC approved for duct applications with an operating air

velocity range of 300 to 4,000 ft/min (1.52 - 20.32 m/sec). The following guidelines

apply.

• Only one duct can be monitored per detector.