5 parameter descriptions / settings, 1 emissivity ε, 1 emissivity – LumaSense Technologies IS 8-GS pro User Manual

Page 19

Series 8 pro Manual

Settings / parameter descriptions 19

5 Parameter descriptions / Settings

The pyrometer is equipped with a wide range of settings for optimal adaptation to the required

measuring condition and to measure the temperature correctly.

5.1 Emissivity

For a correct measurement, it is necessary to adjust the emissivity. The emissivity is the

relationship between the emission of a real object and the emission of a blackbody radiation

source (this is an object which absorbs all incoming rays and has an emissivity of 100%) at the

same temperature.

Different materials have different emissivities ranging between 0% and 100% (settings at the

pyrometer between 10 and 100%, the set value is indicated on the display). Additionally, the

emissivity is dependent on the surface condition of the material, the spectral range of the

pyrometer, and the measuring temperature. The emissivity setting of the pyrometer has to be

adjusted accordingly.

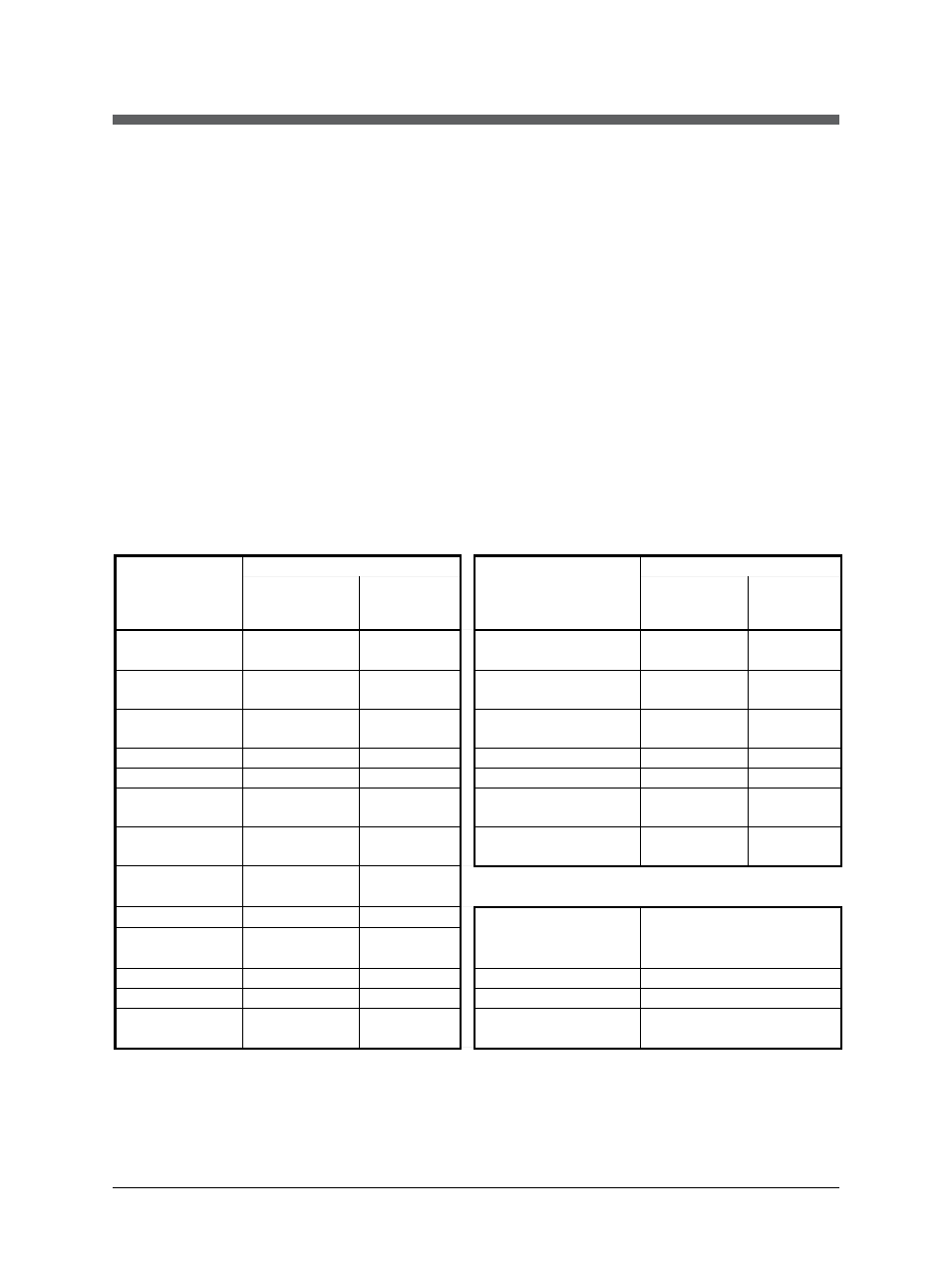

Typical emissivity values of various common materials for the three spectral ranges of the

instruments are listed below. The tolerance of the emissivity values for each material is mainly

dependent on the surface conditions. Rough surfaces have higher emissivities.

Measuring

object

Emissivity [%]

Measuring object

Emissivity [%]

IS 8 plus

IS 8-K plus

(0.78...1.1 µm)

IGA 8 plus

(1.45...1.8 µm)

IS 8 plus

IS 8-K plus

(0.78...1.1 µm)

IGA 8 plus

(1.45...1.8 µm)

“Blackbody

furnace“

100

100

Porcelain glazed

60

60

Steel heavily

scaled

93

85...90

Porcelain rough

80...90

80...90

Steel rolling

skin

88

80...88

Graphite

80...92

80...90

Steel, molten

30

20...25

Refractory bricks

45...60

45...60

Slag

85

80...85

Earthenware, glazed

86...90

80...90

Aluminum,

bright

15

10

Brick

85...90

80...90

Chromium,

bright

28...32

25...30

Soot

95

95

Brass oxidized

(tarnished)

65...75

60...70

Bronze, bright

3

3

Measuring object

Emissivity [%]

IS 8-GS plus

(0.55 µm)

Copper,

oxidized

88

70...85

Zinc

58

45...55

Cast iron (liquid)

40...50

Nickel

22

15...20

Steel (liquid)

20...50

Gold, Silver,

bright

2

2

Melted non-iron

metal

30...50