Condec UPC5010 User Manual

Page 9

6

UPC5000/UPC5010 Operation & Maintenance Manual

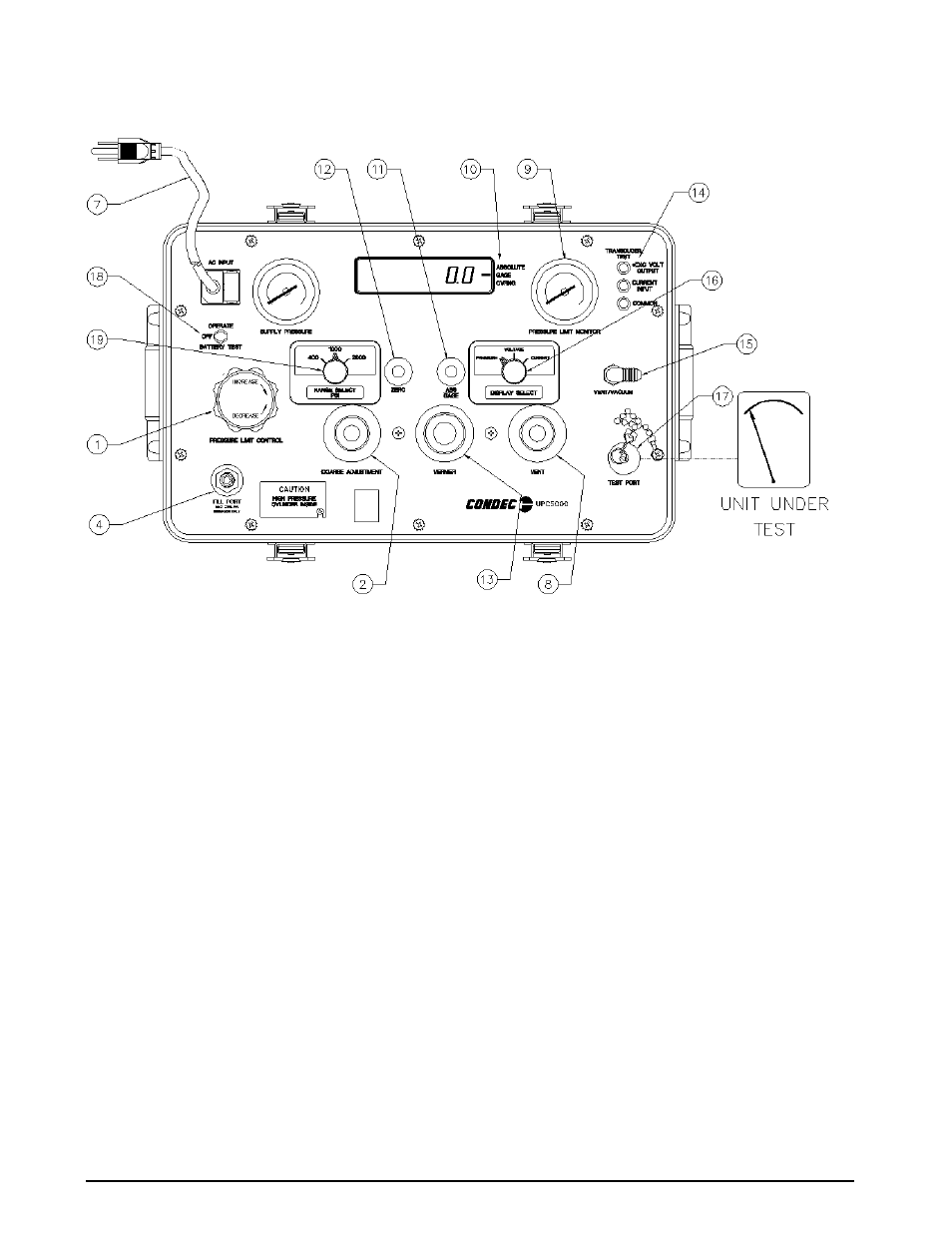

Figure 2-3. Pressure Measurement Sequence (Gage Only)

NOTE

:

UPC5000 shown, AC Input (7) and Fill Port (4) are on back side of UPC5010 Rack Mountable Calibrator.

2.5

Pressure Measurement Sequence for Absolute Only Unit

1. If only pressure measurements greater than barometric are required, continue to step 1.1. If pressure

measurements above and below atmospheric pressure are required, go to Step 2.

1.1.

To apply pressure, close the

VENT

valve (8) (approximately two turns to its stop) and open the

COARSE ADJUSTMENT

valve (2) approximately 1/2 turn counter-clockwise until the numerical

display begins to move. In general, the pressure may be changed rapidly until reaching

approximately 90% of its desired final value.

1.2.

Use either the

COARSE ADJUSTMENT

(2) or

VENT

valve (8) to obtain a specific pressure reading.

Both provide precise control. As the pressure approaches the desired value, the valve being used for

control should be rotated slowly clockwise to its closed position.

1.3.

To obtain exact pressure readings, slowly rotate the

VERNIER

control (13) knob in the direction

required (clockwise to increase pressure) as indicated by the electronic numerical display.

2. If pressure measurements above and below atmospheric pressure are required, connect a vacuum pump

to the

VACUUM/VENT

port (15) as shown in Figure 2-4 on page 7.

3. Open the

VENT

valve (8), close the

COARSE ADJUSTMENT

valve (2) and apply power to the vacuum

pump and allow it to evacuate the system for several minutes or until the digital display reading reaches

equilibrium near zero PSIA. Press the

ZERO

button to establish a zero reference on the display.

4. With the vacuum pump still running, close the

VENT

valve (8) and check for system leaks. If there are

none, continue to step 4.1.

4.1.

To apply pressure, close the

VENT

valve (8) (approximately two turns to its stop) and open the

COARSE ADJUSTMENT

valve (2) (approximately 1/2 turn counter-clockwise until the numerical

display begins to move). In general, the pressure may be changed rapidly until reaching

approximately 90% of its desired final value.