0 maintenance and service, 1 troubleshooting, 2 maintenance and service procedures – Condec UPC5010 User Manual

Page 17: Caution

14

UPC5000/UPC5010 Operation & Maintenance Manual

4.0

Maintenance and Service

This section outlines the mechanical and basic electrical repair procedures for the UPC5000/UPC5010.

4.1

Troubleshooting

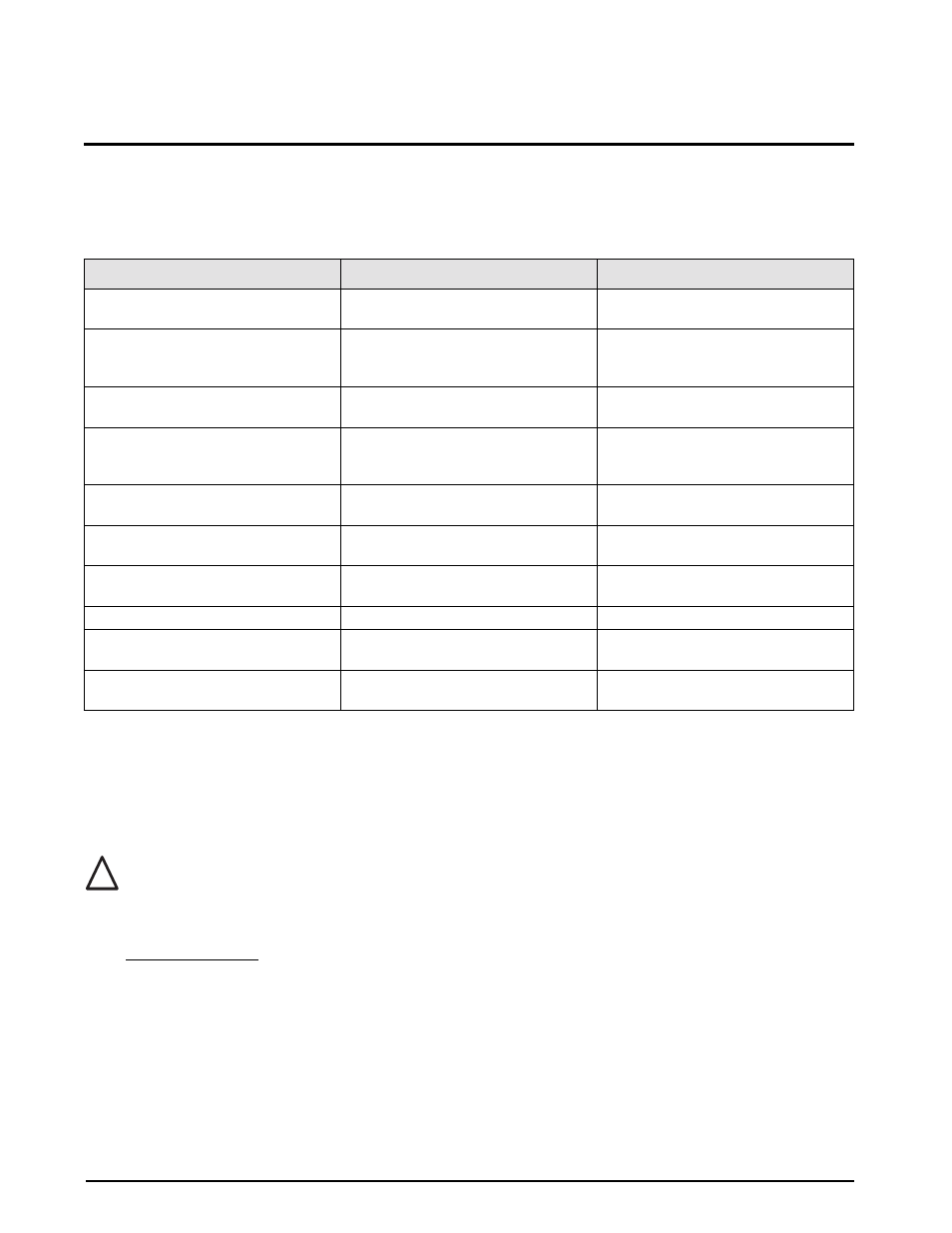

Use Table 4-1 below for information on troubleshooting the UPC5000/UPC5010.

4.2

Maintenance and Service Procedures

The repair procedures cover the major components and sub-assemblies which are critical to the proper

functioning of the calibrators and that need periodic maintenance over the life of the unit. Although some

mechanical sub-assemblies could be replaced without venting cylinder it is not recommended.

Only those persons who are formally trained as skilled technicians should attempt to repair these units.

All safety precautions should be observed due to the presence of electrical components and

high-pressure cylinders. Unit must always be unplugged from power source.

4.2.1

Panel/Chassis Removal and Installation

UPC5000 Removal

Tools required:

Phillips screwdriver

1. Loosen and remove the eight screws (PN 14862) that secure the panel assembly to the enclosure.

2. Lift the panel and chassis by grasping the regulator knob and test port and grasping under the panel

edges. Ensure that the wire harnesses do not catch and snag.

3. Gently set the panel/chassis assembly on a bench top. It can be rested on the panel bottom and chassis

edge with the panel tilted at an angle from its vertical.

Symptom

Problem

Remedy

No lit display

Unit will not energize

Check fuse, check power source, check

power switch

Display slowly decreases over time

Leak in system

Check all compression and pipe fittings

with snoop, bottle of liquid leak gas

detector (PN 64781)

Display does not respond when Vernier

knob is turned

No Vernier control

Readjust isolation valves on Orion;

replace O-ring on Vernier piston

Display increases or decreases when

COARSE (Pressure) or VENT valves are

closed

No Pressure or Vent control

Replace valve seats or O-rings in valves;

check valve needles

Unit will not stay in CAL; display shows

"o" and reads a high value at zero PSIG.

Transducer over-pressurized

Replace transducer

Low battery indicator on display

illuminates when unit is powered

Low or no battery power

Re-charge battery, check power supply

charging voltage

No display when in battery mode after

charging

Battery will not hold charge

Replace battery

Display will not zero

Display will not zero

Perform a ZERO/SPAN calibration

Display shifts

Transducer drifts or possible over

pressure

Replace transducer

Gas escapes when external supply

pressure is bled

Nitrogen cylinder will not remain charged Remove inlet check valve; clean or

replace

Table 4-1. UPC5000/UPC5010 Troubleshooting

!

Caution