0 calibration, 1 pneumatic calibration set-up, 2 instrument calibration set-up – Condec UPC5010 User Manual

Page 11

8

UPC5000/UPC5010 Operation & Maintenance Manual

3.0

Calibration

Follow the procedure on the following pages for calibrating the UPC5000/UPC5010.

NOTES:

•

When calibrating, the computer within the UPC5000/UPC5010 is actually being re-programmed, therefore it is

important that the pressure standard being used is in satisfactory operating condition and that the technician

fully understands its operating characteristics and methods of usage. In addition, the UPC5000/UPC5010 itself

must be properly warmed up (approximately ten minutes) and electrically stabilized prior to performing a

calibration cycle.

•

The CONDEC Repair Lab is equipped to do calibrations on CONDEC calibrators and pressure standards.

Calibrations include a certification and are traceable to N.I.S.T (see “UPC5000/UPC5010 Return Material

Authorization Form” on page 53).

3.1

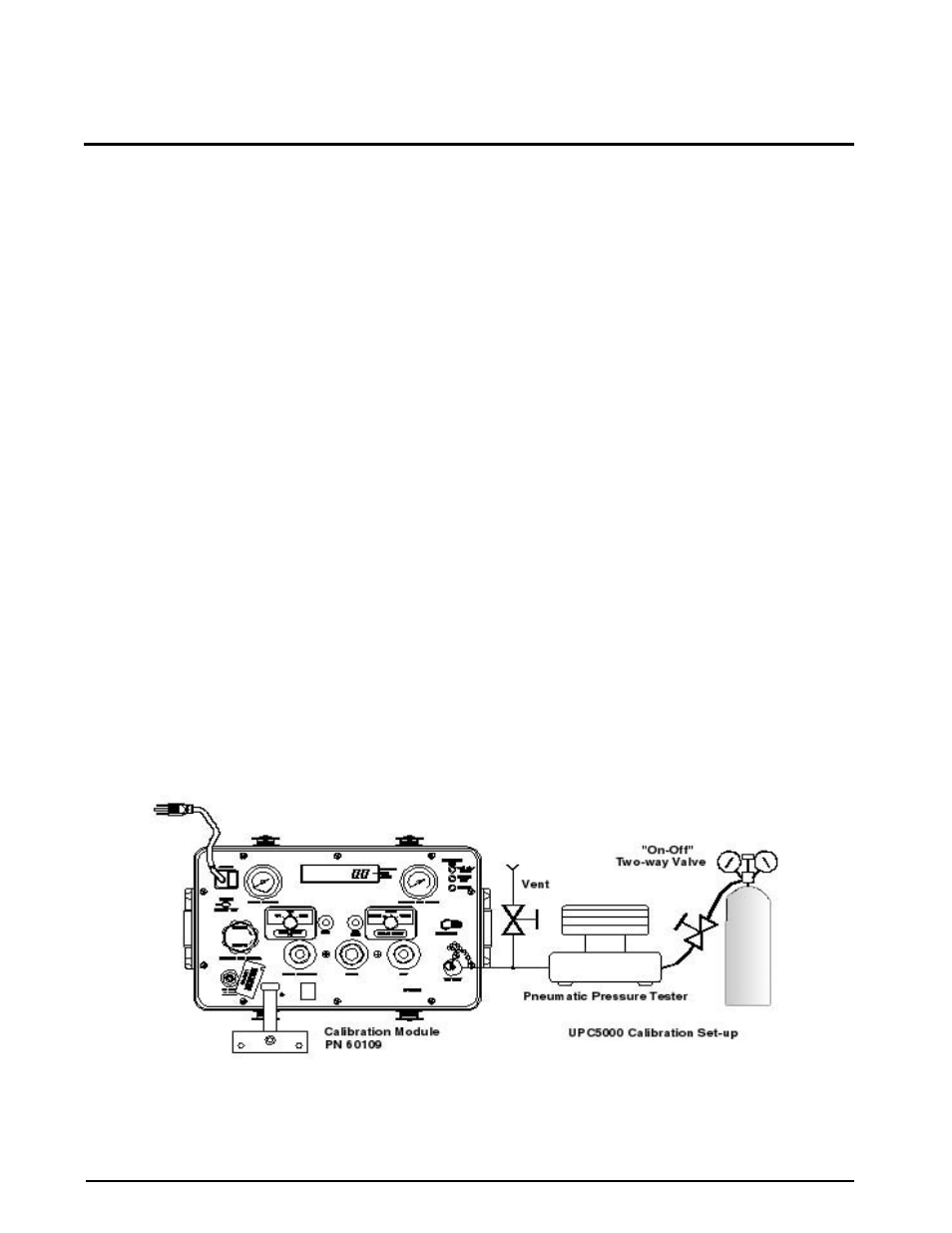

Pneumatic Calibration Set-up

Figure 3-1 defines a typical gage or absolute/gage calibration set-up using a floating piston-type, dead weight

tester. While doing an ABSOLUTE Only Unit calibration, a vacuum pump with an indicator capable of reading

PSIA will be required where the dead weight tester/pressure source is shown in Figure 3-1. This enables going

below local barometric pressure.

NOTE:

Any type of precision pressure or vacuum standard is acceptable as long as its basic accuracy is ±0.025% of

point or better.

To permit proper calibration, at least an

ON/OFF

and a

VENT

valve (connected as shown in Figure 3-1) must be

provided.

3.2

Instrument Calibration Set-up

The UPC5000/UPC5010 is placed into its calibrate mode by connecting a Condec Calibration Module (PN

60109) via the multi-pin jack. The jack is located behind the small slide plate near the fill port (see Figure 3-1).

The Condec Calibration Module provides access to the calibrator’s various program modes via a five-position

rotary switch. It also provides a means of entering and storing data via four other momentary action switches.

In the calibrate mode, the UPC5000/UPC5010’s numerical display is used to provide operator prompting

symbols as well as displaying the various data formats. For example, in Figure 3-2, the data format shown is that

obtained as soon as the

ZERO/SPAN

position of the rotary switch is selected.

Figure 3-1. Gage Only Unit or Absolute/Gage Unit nstrument Calibration Set-up

NOTE:

UPC5000 shown, AC input and Fill Port are on backside of UPC5010 Rack Mountable Calibrator.