Condec UPC5010 User Manual

Page 5

2

UPC5000/UPC5010 Operation & Maintenance Manual

•

Calibration Integrity: Once calibrated, the tamper-proof design provides numerous safeguards that

guarantee the integrity of pressure readings obtained. The LED provides the operator with status

information during both operation and calibration.

•

Pressure Source: An internal supply cylinder with a volume of 7.0 std. cu. ft. of N

2

provides up to 2216

PSIG of pressure for calibration and test. A check valve quick disconnect fitting provides re-charging

capability.

•

Simple Operation: All controls, indicators and pressure ports are accessible from the front panel. Section 2

provides clear, concise instructions for system operation.

•

Data Input Capability: A front panel-mounted connector and selector switch permit the 4-20 mA current

signal from the gage-under-test or voltage to be displayed. Transducer excitation voltage of 18 VDC can be

provided standard, or by special order 28 VDC.

•

Safe, Clean Operation: All pressure components are made of brass, copper, aluminum or stainless steel and

proof-tested to at least 150% of maximum operating pressure. In addition, the system contains a

high-pressure burst disk and relief valves to protect both the operator and system components from harm in

the event of over-pressurization. An all stainless steel version is available by special order.

The heart of this calibration system is a highly stable and repeatable pressure transducer. These sensors produce

an electrical output signal which is linearly proportional to the applied pressure.

By combining these sensors with microprocessor-based circuitry, an even higher degree of operational accuracy

and precision has been accomplished. For example, computer-generated correction curves for both the

non-linearity and the hysteresis of the sensors improve these characteristics by an order of magnitude or more. In

addition, a self-check feature ensures long-term accuracy by utilizing the computer to generate and control an

internal shunt calibration mode of operation. The indicators full-scale reading is compared against, and if

necessary, corrected to the digitally-stored value for full scale obtained at the time of initial pressure calibration.

The computer is programmed with a series of internal self-diagnostic routines that continually monitor and check

every bit of data stored and processed by this system. The system either notes or shuts down operation in the

event of an out-of-tolerance reading or outright failure.

The UPC5000 has an internal, rechargeable 12 volt lead acid battery, that provides a minimum of six hours of

complete portability when fully charged. An ON/OFF and battery test switch is provided to conserve energy

when the instrument is not in use and to provide the operator with battery voltage status during use. It also has a

LO BATT

indicator on display.

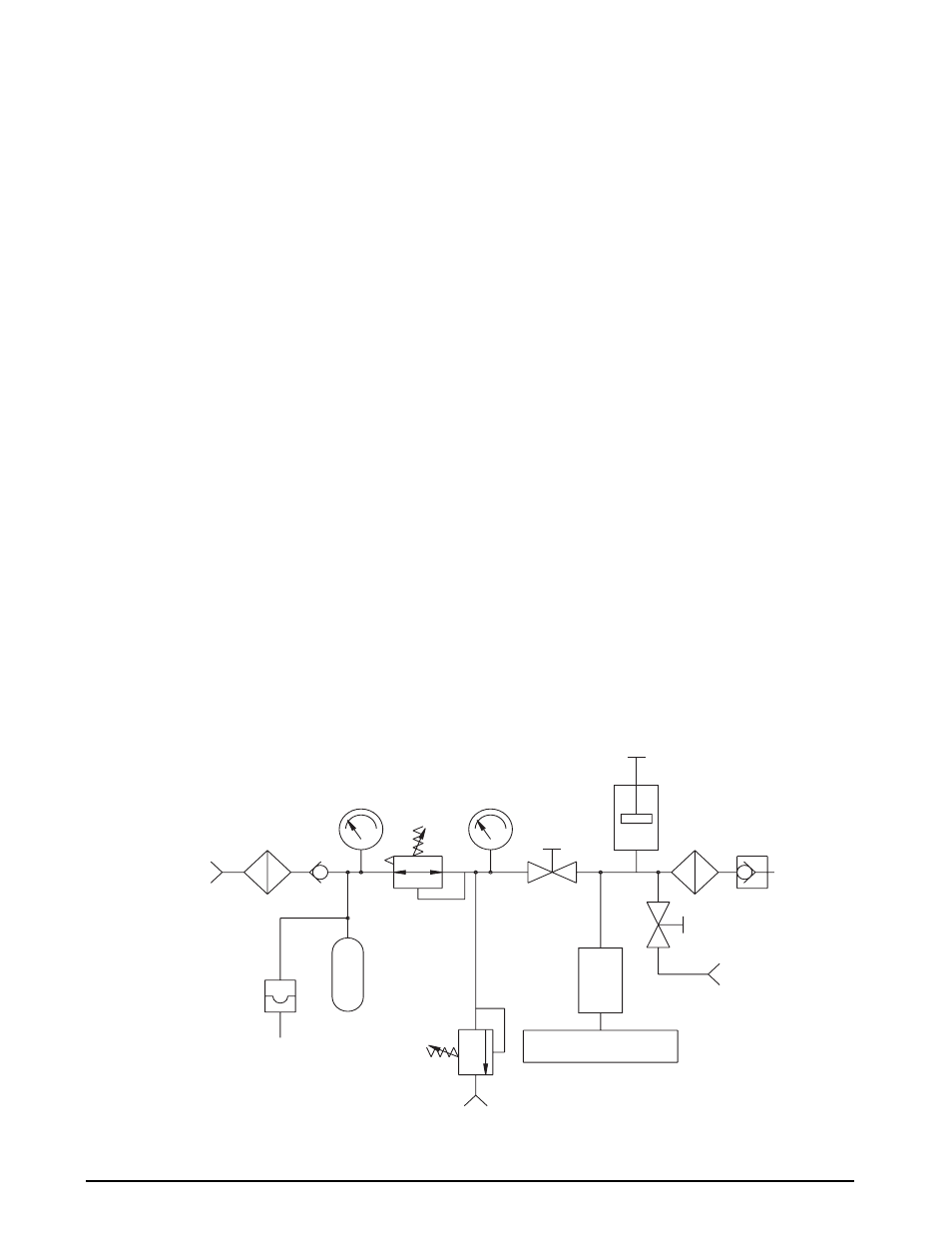

The following schematic provides an overview of the UPC5000/UPC5010’s function.

Figure 1-1. UPC5000/UPC5010 Flow Diagram

VALVE

CHECK

MONITOR

PRESSURE LIMIT

RELIEF

VALVE

2216 PSI MAX.

N FILL PORT

2

+ or - 50 PSI

3000 PSI

BURST DISK

2216 PSI MAX.

N SUPPLY

INTERNAL

CONTROL

PRESSURE LIMIT

2

SUPPLY PRESSURE

FILTER

10u

0-3000 PSI

MICROPROCESSOR-BASED

DIGITAL INDICATOR

TRANSDUCER

VENT

VENT/VACUUM

PORT

(QUICK DISCONNECT)

PRESSURE

INCREASE

VERNIER

TEST PORT

20u

FILTER

ADJUST