Maintenance, 1. overall dissolved oxygen metering system, Maintenance -1 – Yokogawa DO402 Dissolved Oxygen Analyzer User Manual

Page 75: 1. overall dissolved oxygen metering system -1

IM 12J05D02-01E

Maintenance 7-1

7. MAINTENANCE

It is important for maintaining the measurement accuracy of the EXA DO series of wire dissolvedoxygen

metering system to perform inspection and maintenance at fixed intervals. It also serves to prevent prob-

lems from arising.

This chapter describes daily inspection and maintenance for the purpose of maintaining system perform-

ance.

7-1. Overall dissolved oxygen metering system

Tables 7-1 and 7-2 show the inspection and maintenance items for equipment composing 4-wire dis-

solved-oxygen metering system. The procedure of inspection and maintenance for the dissolved oxygen

converter is described in Section 7-2. For inspection and maintenance of the sensors and holders, see

each user’s manual respectively.

7-1-1. Inspection and maintenance to be implemented periodically

Table 7-1 shows the items which are recommended to be inspected and maintained periodically.

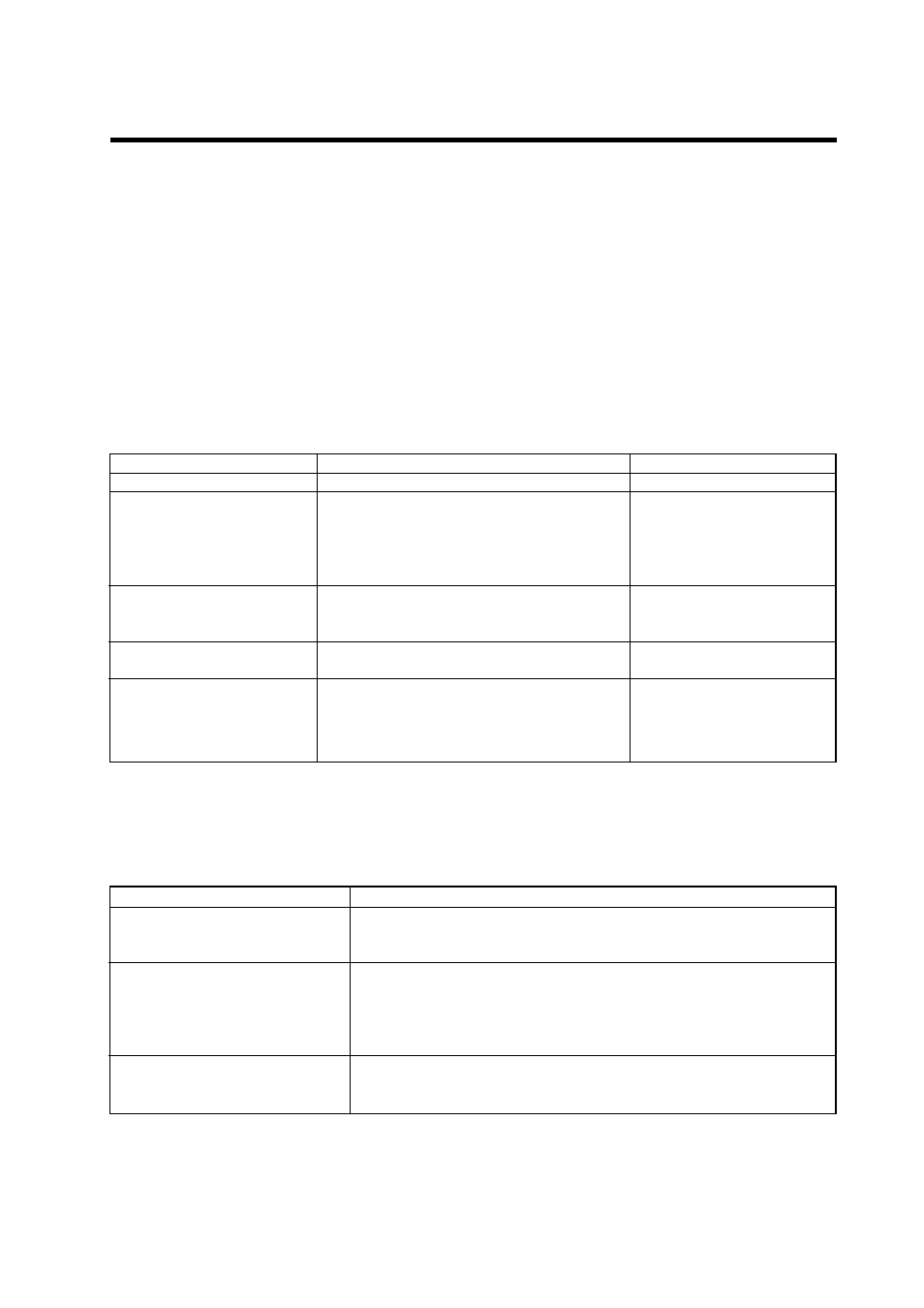

Table 7-1. Items for periodic inspection and maintenance of 4-wire dissolved-oxygen metering system

7-1-2. Inspection and maintenance to be implemented on occasion

Occasionally implement the maintenance that is not directly related to measurement functions and main-

tenance associated with errors.

Table 7-2. Items for occasional inspection and maintenance of 4-wire dissolved-oxygen metering

Instrument or apparatus

Item

Recommended Interval

All equipment

a. Calibration

a. 1 to 2 months

Dissolved oxygen sensor

a. Clean the tip of the sensor

a. 1 to 2 months

b. Polishing of (silver) electrode

b. 6 to 8 months

surface and replacement of electrolyte

c. Replacement of membrane assembly

c. 6 to 8 months

d.

Replacement of sensor cap

d. 6 to 12 months

Dissolved oxygen converter a. Inspection of temperature indication

a. 6 months

(error check)

b. Replacement of fuse

b. 1 to 2 years

Float holder

a. Sweeping of winch mechanism

a. (depends on installation

environment)

Immersion holder

a. Inspection of sensor holding O-ring

a. 6 months

b. Sweeping of cleaner nozzle

b. 1 to 2 months

c. Inspection for leakage from the solenoid c. 6 months

valve for cleaning utility

Faulty phenomenon

System content of inspection

Error E2 occurrence

Check whether the dissolved-oxygen sensor membrane is

contaminated or not.

Check whether the nozzle is clogged or not.

Error E3 occurrence

Polish the silver electrode surface of the galvanic dissolved-

oxygen sensor, platinum surface of the polarographic dissolved-

oxygen sensor, and replace the electrolyte. Check that the

connection between sensor and sensor cable is fit, and LED

emission of the optical dissolved-oxygen sensor.

It is difficult to see the inside

Wipe off the dirt on the transparent window using tissue paper or

of the converter through the

the like. (Use detergent for hard-to-clean dirt.)

window