5. wiring the analog output signals, 5-1. general precautions, 5-2. analog output signals – Yokogawa DO402 Dissolved Oxygen Analyzer User Manual

Page 29: 6. wiring the standard galvanic sensor, 5. wiring the analog output signals -9, 5-1. general precautions -9, 5-2. analog output signals -9, 6. wiring the standard galvanic sensor -9

IM 12J05D02-01E

Installation and wiring 3-9

3-5. Wiring the analog output signals

3-5-1. General precautions

The analog output signals of the EXA transmit low power standard industry signals to peripherals like

control systems or strip-chart recorders (Figure 3-6).

3-5-2. Analog output signals

The output signals consist of active current signals of either 0-20 mA or 4-20 mA. The maximum load

can be 600 ohms on each.

It should be necessary to use screening/shielding on the output signal cables. Terminal 63 is used to

connect the shielding.

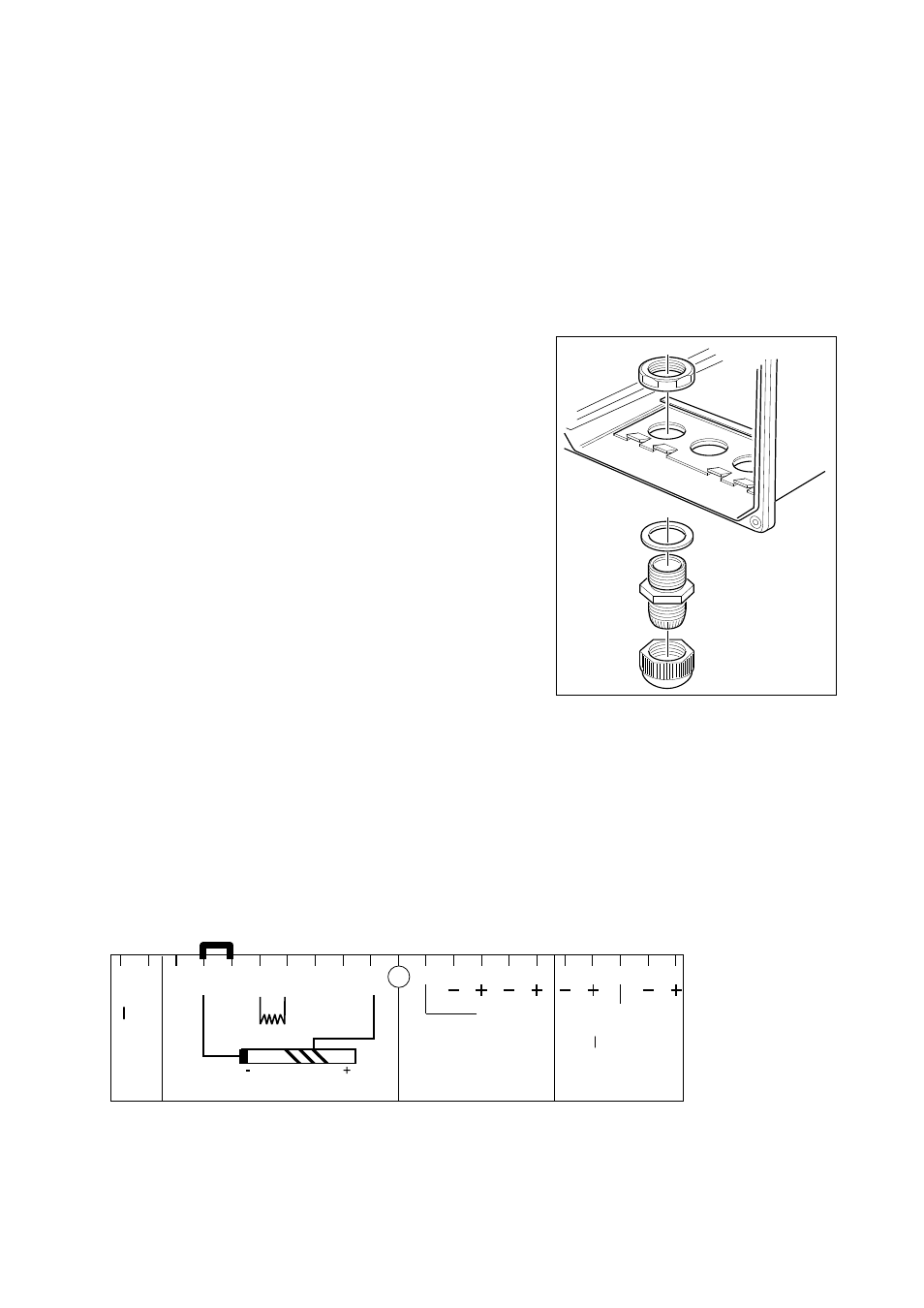

3-6. Wiring the standard galvanic sensor

The sensor cable has markers on the individual wires.

These markings refer to the markers on the terminals.

The temperature compensator has two wires with the markings

T1, T2 and/or 11, 12 and must be connected to terminal 11

and 12.

The measuring electrode: the cathode is marked with IE and/or 13

and must be connected to terminal 13.

The reference electrode: the anode is marked with RE and/or

15 and must be connected to terminal 15.

The liquid earth ( solution ground) is marked with 16 and must

be connected to terminal 16.

Note:

The liquid earth (solution ground) connection is valid

only when the floating ball holder, Model PB350G or

PB360G, is used. Otherwise, do not make a connection

to terminal 16. The connection, if made, may result in

abnormal readings. Even if the floating ball holder is

used, when the liquid earth (solution ground) connection is not used, then disconnect the wiring

to terminal 16. (The disconnected wire should be covered with an insulating tube to avoid contact

with other terminals.)

The overall shield of the cable is marked with 14 and must be connected to terminal 14.

Note:

A jumper cable is placed to connect converter terminals 13 and 17.

Make sure that connecting the sensor cable to the IE pin or pin 13 or pulling the sensor cable

does not cause the jumper cable to come loose. Insufficient tightening may cause unstable or

false measurements.

F0309.ai

Digital

Commnucations

12

13

15

16

63 66 65 62 61 95 94 93 92 91

SCREEN

mA2

mA1

SCREEN

TL

TL

17 11

CONT

m

A OUTPUT

14

22

21

18

SCREEN

99

SCREEN 2

23

mA Output

(IE)

(T1) (T2)

(RE)

(LE)

Short

Sensor Input

Contact

Input

Shield

Temp.

Liquid Earth

Wirning galvanic Sensor

Figure 3-11. Wirning galvanic sensor

Figure 3-10. Cable gland assembly