Yokogawa EJX115A User Manual

Page 52

<9. General Specifications>

9-6

IM 01C25K01-01E

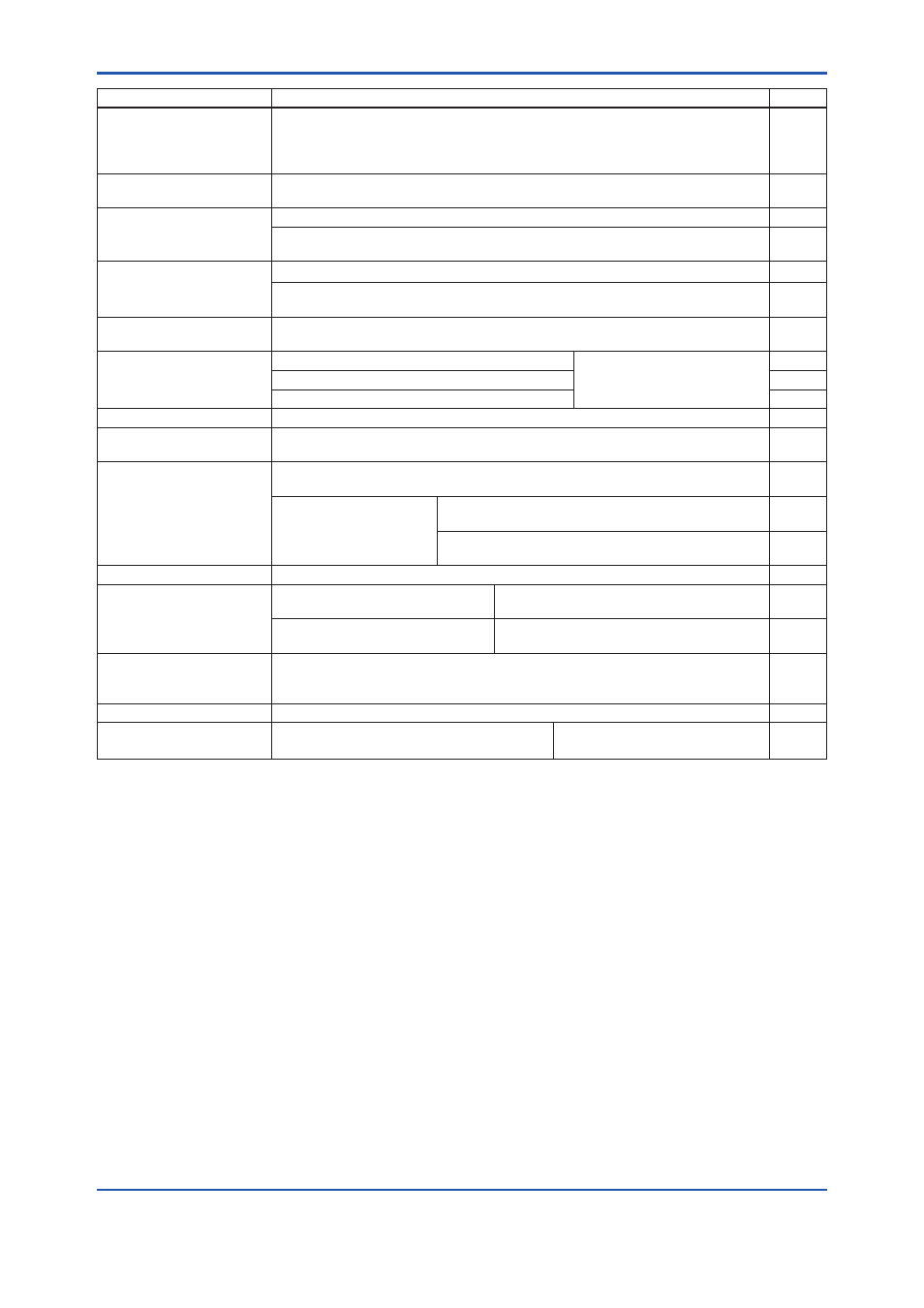

Item

Description

Code

Lightning protector

Transmitter power supply voltage:

10.5 to 32 V DC (10.5 to 30 V DC for intrinsically safe type.)

Allowable current: Max. 6000 A (1×40 μs), Repeating 1000 A (1×40 μs) 100 times

Applicable Standards: IEC 61000-4-4, IEC 61000-4-5

A

Status output *

4

Transistor output (sink type)

Contact rating: 10.5 to 30 VDC, 120 mA DC(max) Low level: 0 to 2 VDC

AL

Oil-prohibited use

Degrease cleansing treatment.

K1

Degrease cleansing treatment and with fluorinated oilfilled capsule.

Operating temperature –20 to 80°C( –4 to 176°F)

K2

Oil-prohibited use with

dehydrating treatment

Degrease cleansing and dehydrating treatment.

K5

Degrease cleansing and dehydrating treatment with fluorinated oilfilled capsule.

Operating temperature –20 to 80°C( –4 to 176°F)

K6

Capsule fill fluid

Fluorinated oil filled in capsule

Operating temperature –20 to 80°C( –4 to 176°F)

K3

Calibration units *

5

P calibration (psi unit)

(See Table for Span and

Range Limits.)

D1

bar calibration (bar unit)

D3

M calibration (kgf/cm

2

unit)

D4

Gold-plated diaphragm

Surface of isolating diaphragm is gold plated, effective for hydrogen permeation.

A1

Long vent *

6

Total length: 119 mm (standard: 34 mm); Total length when combining with

Optional code K1, K2, K5, and K6: 130 mm. Material: 316 SST.

U1

Output limits and failure

operation *

7

Failure alarm down-scale: Output status at CPU failure and hardware error is

–5%, 3.2 mA DC or less.

C1

NAMUR NE43 Compliant

Output signal limits:

3.8 mA to 20.5 mA

Failure alarm down-scale: Output status at CPU

failure and hardware error is –5%, 3.2 mA DC or less.

C2

Failure alarm up-scale: Output status at CPU

failure and hardware error is 110%, 21.6 mA or more.

C3

Stainless steel tag plate

304 SST tag plate wired onto transmitter (316 SST when /HC is specified)

N4

Data configuration at

factory *

8

Data configuration for HART

communication type

Software damping, Descriptor, Message

CA

Data configuration for BRAIN

communication type

Software damping

CB

Advanced diagnostics *

14

Multi-sensing process monitoring

• Impulse line blockage detection *

15

• Heat trace monitoring

DG6

Material certificate *

13

Cover flange, Process connector, Manifold, Orifice, and Spacer

M12

Pressure test/

Leak test certificate *

12

Test Pressure: 16 MPa (2300 psi)

Nitrogen(N

2

) Gas *

11

Retention time: one minute

T12

Contact Yokogawa representative for the codes indicated as ‘-’.

*1: Applicable for Electrical connection code 2, 4, 7, 9, C, and D.

*2: Not applicable for option code /AL.

*3:

Not applicable with color change option.

*4:

Check terminals cannot be used when this option code is specified. Not applicable for output signal code F.

*5:

The unit of MWP (Max. working pressure) on the name plate of a housing is the same unit as specified by option codes D1, D3, and

D4.

*6:

Applicable for vertical impulse piping type (Installation code 2, 3, 6, or 7) .

*7:

Applicable for output signal codes D, E and J. The hardware error indicates faulty amplifier or capsule.

*8:

Also see ‘Ordering Information’.

*9:

Not applicable for amplifier housing code 2.

*10: 316 or 316L SST. The specification is included in amplifier code 2.

*11: Pure nitrogen gas is used for oil-prohibited use (option codes K1, K2, K5, and K6).

*12: The unit on the certificate is always Pa unit regardless of selection of option code D1, D3 or D4.

*13: Material traceability certification, per EN 10204 3.1B.

*14: Applicable only for output signal code -E and -J.

*15: The change of pressure fluctuation is monitored and then detects the impulse line blockage. See TI 01C25A31-01E for detailed

technical information required for using this function.