5 troubleshooting, 1 basic troubleshooting, Troubleshooting -6 8.5.1 – Yokogawa EJX115A User Manual

Page 43: Basic troubleshooting -6, Important

<8. Maintenance>

8-6

IM 01C25K01-01E

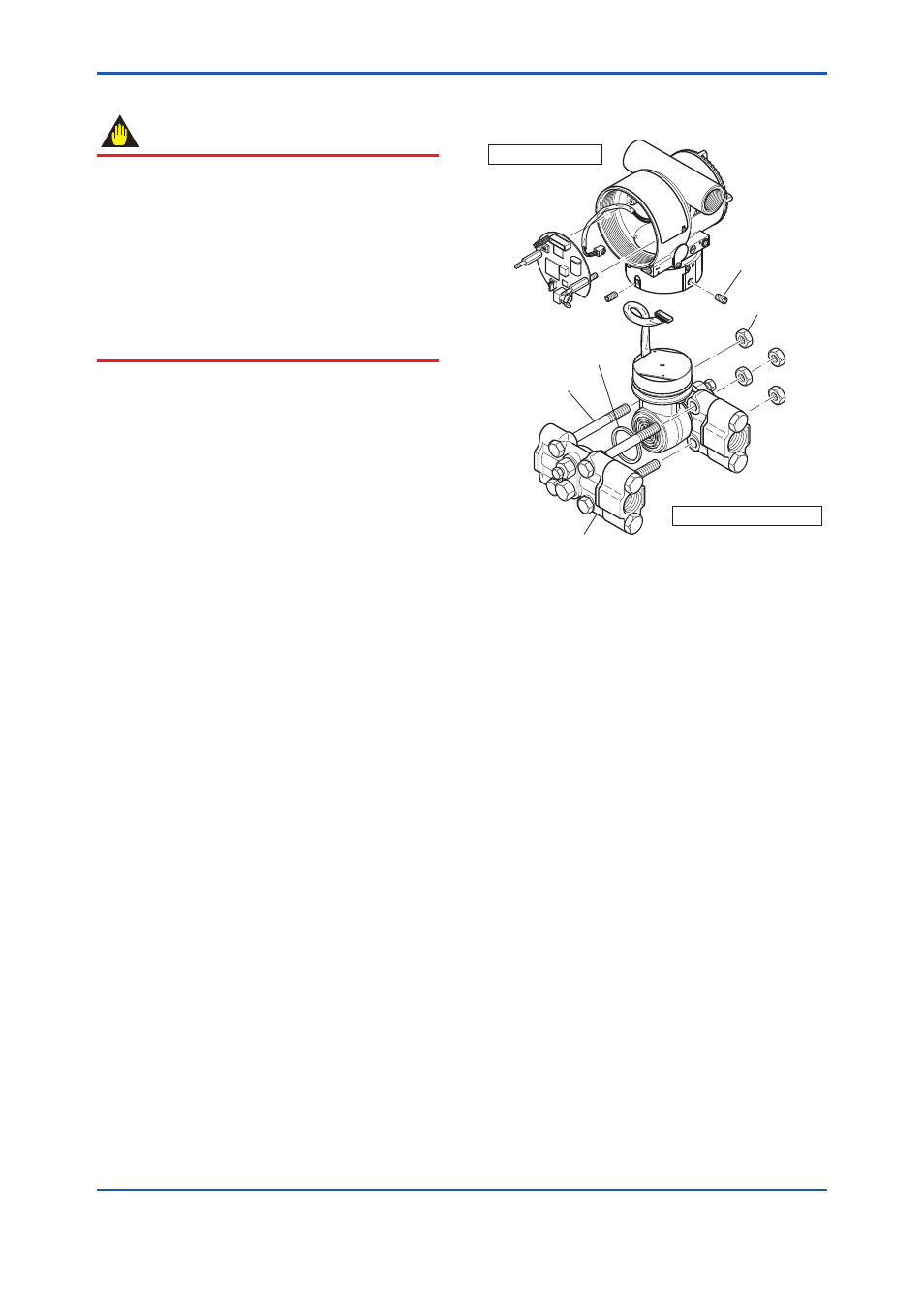

■ Removing the Capsule Assembly

IMPORTANT

Exercise care as follows when cleaning the

capsule assembly.

• Handle the capsule assembly with care, and

be especially careful not to damage or distort

the diaphragms that contact the process

fluid.

• Do not use a chlorinated or acidic solution for

cleaning.

• Rinse thoroughly with clean water after

cleaning.

1) Remove the CPU assembly as shown in

subsection 8.4.2.

2) Remove the two setscrews that connect the

transmitter section and pressure-detector

section.

3) Remove the hexagon-head screw and the

stopper.

4) Separate the transmitter section and pressure-

detector section.

5) Remove the nuts from the four flange bolts.

6) While supporting the capsule assembly with

one hand, remove the cover flange.

7) Remove the capsule assembly.

8) Clean the capsule assembly or replace with a

new one.

■ Reassembling the Capsule Assembly

1) Insert the capsule assembly between the flange

bolts, paying close attention to the relative

positions of the H (high pressure side) and

L (low pressure side) marks on the capsule

assembly.

Replace the two capsule gaskets with new

gaskets.

2) Install the cover flange on the high pressure

side, and use a torque wrench to tighten the

four nuts uniformly to a torque 17 N·m (40 N·m

for measurement span code F.)

3) After the pressure-detector section has been

reassembled, a leak test must be performed to

verify that there are no pressure leaks.

4) Reattach the transmitter section to the

pressure-detector section.

Reattach the stopper with the hexagon-head

screw.

5) Tighten the two setscrews. (Tighten the screws

to a torque of 1.5 N·m)

6) Install the CPU assembly according to

subsection 8.4.2.

7) After completing reassembly, adjust the zero

point and recheck the parameters.

F0806.ai

Transmitter section

Pressure-detector section

Cover flange

Capsule gasket

Flange bolt

Setscrew

Nut

Figure 8.6

Removing and Mounting the Pressure-

detector Section

8.5 Troubleshooting

If any abnormality appears in the measured values,

use the troubleshooting flow chart below to isolate

and remedy the problem. Since some problems

have complex causes, these flow charts may

not identify all. If you have difficulty isolating or

correcting a problem, contact Yokogawa service

personnel.

8.5.1 Basic Troubleshooting

First determine whether the process variable

is actually abnormal or a problem exists in the

measurement system.

If the problem is in the measurement system,

isolate the problem and decide what corrective

action to take.

This transmitter is equipped with a self-diagnostic

function which will be useful in troubleshooting,

and the transmitter equipped with an integral

indicator will show an alarm code as a result of self-

diagnosis.

See subsection 8.5.3 for the list of alarms.

See also each communication manual.