Operation, 1 preparation for starting operation, Operation -1 – Yokogawa EJX115A User Manual

Page 31: Preparation for starting operation -1

<7. Operation>

7-1

IM 01C25K01-01E

7. Operation

7.1 Preparation for Starting

Operation

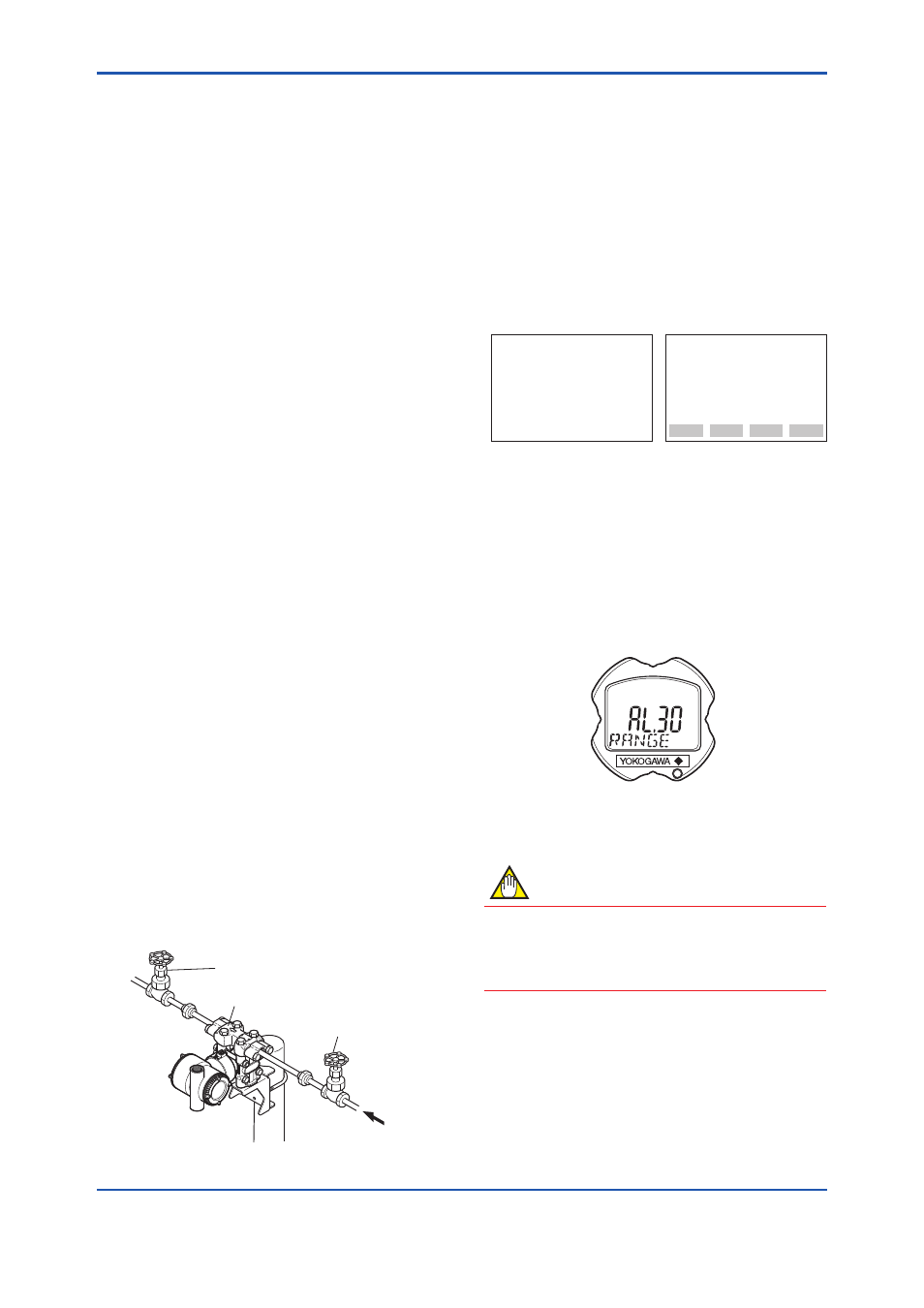

The Model EJ115 low flow transmitter

measures the flow rates of liquids and gases. This

section describes the operation procedure for the

EJ115 as shown in Figure 7.1 (vertical impulse

piping type, high-pressure connection: right side)

when measuring a liquid flow rate.

(a) Follow the procedures below to introduce

process pressure into the transmitter.

1) Open the stop valve on the downstream side.

2) Gradually open the stop valve on the upstream

side to introduce process fluid into the

transmitter pressure-detector section.

This will cause process fluid to flow into the

orifice built in the manifold, and apply flow-

dependent differential pressure to the high and

low pressure sides of the transmitter.

3) Confirm that there are no pressure leaks in the

stop valves on the upstream and downstream

sides, process piping connection or transmitter,

etc.

(b) Venting Gas from the Transmitter Pressure-

detector Section.

Since the piping in the example of Figure 7.1

is constructed to be self-venting, no venting

operation is required. If it is not possible

to make the piping self-venting, refer to

Subsection 7.6 for instructions.

(c) Turn ON power and connect the BT200.

Open the terminal box cover, and connect the

BT200 to the SUPPLY + and – terminals.

(d) Using the BT200, confirm that the transmitter is

operating properly. Check parameter values or

change the setpoints as necessary.

If the transmitter is equipped with an integral

indicator, its indication can be used to confirm

that the transmitter is operating properly.

Stop valve(downstream side)

Stop valve

(upstream side)

Manifold

F0701.ai

Figure 7.1

Liquid Flow Measurement

Confirming that Transmitter is Operating

Properly

Using the BT200

• If the wiring system is faulty, ‘communication

error’ appears on the display.

• If the transmitter is faulty, ‘SELF CHECK

ERROR’ appears on the display.

communication error

PARAM

C60:SELF CHECK

ERROR

Communication error

(Faulty wiring)

Self-diagnostic error

(Faulty transmitter)

DATA

DIAG

PRNT

ESC

F0702.ai

Figure 7.2

BT200 Display

Using the integral indicator

• If the wiring system is faulty, the display stays

blank.

• If the transmitter is faulty, an error code is

displayed.

Self-diagnostic error on the integral indicator

(Faulty transmitter)

F0703.ai

Figure 7.3

Integral Indicator with Error Code

NOTE

If any of the above errors are indicated on

the display of the integral indicator or the

communicator, refer to subsection 8.5.3 for the

corrective action.