Installing impulse piping, 1 process piping installation precautions, 1 connecting process piping to the transmitter – Yokogawa EJX115A User Manual

Page 26: 2 routing the process piping, Installing impulse piping -1, Process piping installation precautions -1 5.1.1, Connecting process piping to the transmitter -1, Routing the process piping -1

<5. Installing Impulse Piping>

5-1

IM 01C25K01-01E

5. Installing Impulse Piping

5.1 Process Piping Installation

Precautions

The manifold contains a small-bore orifice. For

the transmitter of a high pressure connection right

side, the orifice is placed facing such a direction

as to enable normal flow measurement when fluid

is flowed from right to left (as viewed from the

front). If the orifice is removed from the manifold,

it must be replaced facing the correct direction.

(For disassembly and reassembly procedures, see

Subsection 8.4.4)

Pay careful attention to the following points when

routing the process piping and connection the

process piping to the transmitter.

5.1.1 Connecting Process Piping to the

Transmitter

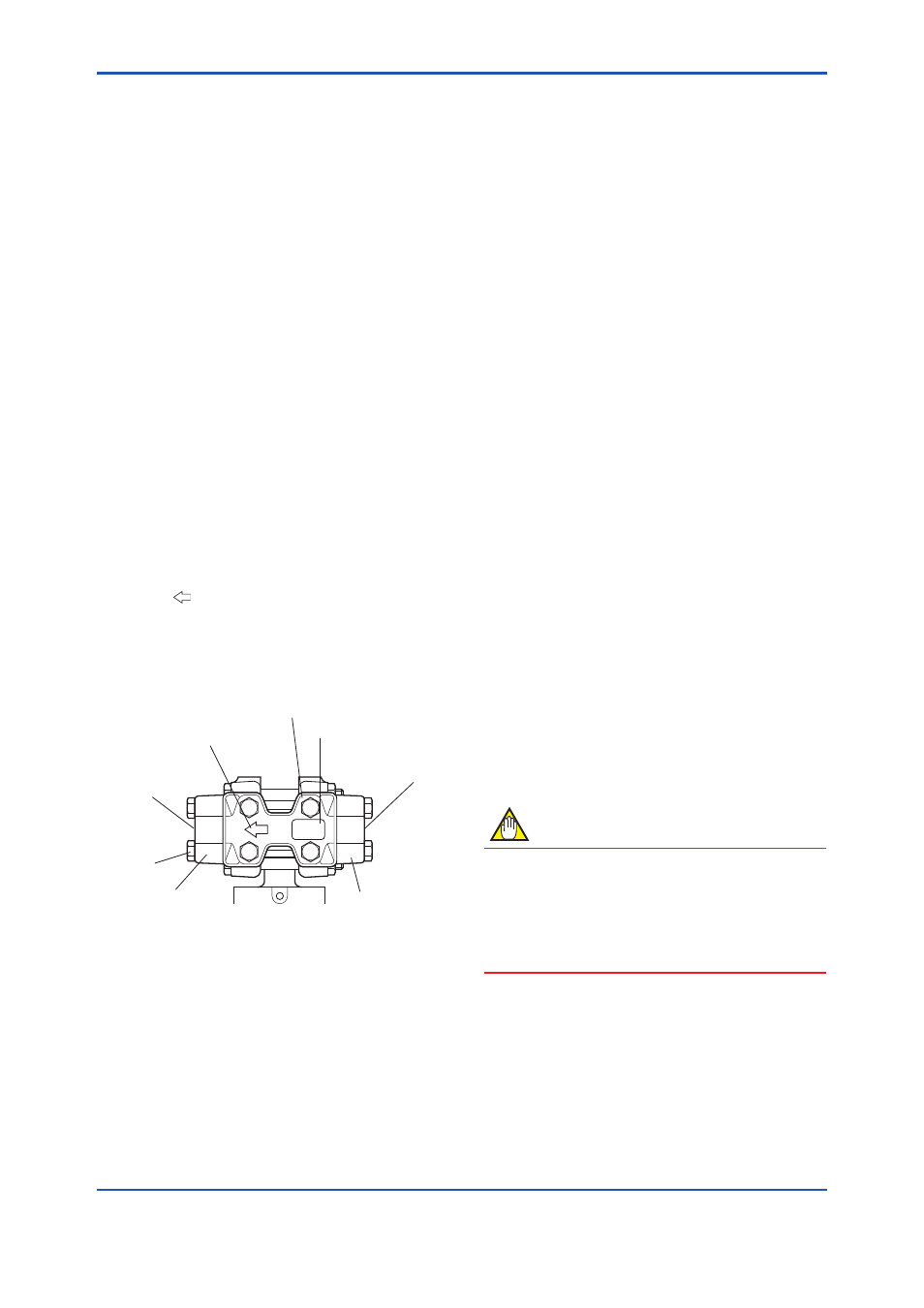

(1) Confirming the Process Fluid Flow

Direction (Figure 5.1)

The mark “ ” on the manifold indicates the

direction in which the process fluid is flowed (from

right to left). When connecting the process piping

to the process connector, confirm the process fluid

flow direction.

F0501.ai

Flow direction(from right to left)

Manifold

Orifice name plate

Process connector

(low pressure side)

Process connector

(high pressure side)

Process connection

(outflow side)

Process connection

(inflow side)

Bolt

Figure 5.1

Manifold and Flow Direction Indication

(2) Tightening the Process Connector

Mounting Bolts

The transmitter is shipped with the process

connector mounting bolts only loosely tightened.

After connecting the process piping, tighten these

bolts uniformly to prevent leaks with a torque of 39

to 49 N·m {4 to 5 kgf·m}.

(3) Removing the Process Connector Port

Dustproof Cap

The process connector port threads are covered

with a plastic cap to exclude dust. This cap must be

removed before connecting the piping. (Be careful

not to damage the threads when removing this cap.

Never insert a screwdriver or other tool between the

cap and port threads to remove the cap.)

5.1.2 Routing the Process Piping

(1) Relationship between Process Fluid

and Manifold Locations (For the vertical

impulse piping type)

If condensate (or gas) generated in the process

piping were allowed to accumulate, then it would be

necessary to remove it periodically by opening the

drain (or vent) plug. However, this would generate a

transient disturbance in the pressure measurement.

Therefore, the process piping must be routed so

that any condensate (or gas) generated in the

process piping will not accumulate in the pressure-

sensing assembly of the transmitter.

NOTE

• If the process fluid is a gas, then as a rule the

manifold must be located at the downside of

the pressure-sensing assembly. (Figure 5.2)

• If the process fluid is a liquid, then as a rule

the manifold must be located at the upside of

the pressure-sensing assembly. (Figure 5.3)

(2) Pipe Size for Process Piping

Use a 15 mm (1/2-inch) pipe for process piping

connection to the process connector.