2 zero point adjustment, 3 starting operation, Zero point adjustment -2 – Yokogawa EJX115A User Manual

Page 32: Starting operation -2, Important

<7. Operation>

7-2

IM 01C25K01-01E

Verify and Change Transmitter

Parameter Setting and Values

The parameters related to the following items are

set at factory as specified in order.

• Calibration range

• Integral indicator display

• Output mode

• Software damping (optional)

Other parameters like following are shipped with the

default setting.

• Low-cut

• Process alarm setting

• Static pressure range

• Signal characterizer

• Write protection

To confirm or change the values, see IM 01C25T01-

06EN or 01C25T03-01E.

7.2 Zero Point Adjustment

After completing preparations for operating the

transmitter, adjust the zero point.

Zero point adjustment can be done by turning the

transmitter’s zero-adjustment screw or by using

the communicator. This section describes the

procedure for the zero-adjustment screw. For the

communicator procedure, see the communication

manual.

IMPORTANT

Do not turn off the power to the transmitter

immediately after performing a zero point

adjustment. Powering off within 30 seconds of

performing this procedure will return the zero

point to its previous setting.

NOTE

Before performing this adjustment, make sure

that the external zero adjustment function has

NOT been disabled by a parameter setting.

To check the output signal, use a digital multimeter,

calibrator, or communicator.

Adjusting Zero Point for Differential

Pressure Transmitters

Before adjusting zero point, make sure that the

equalizing valve is open.

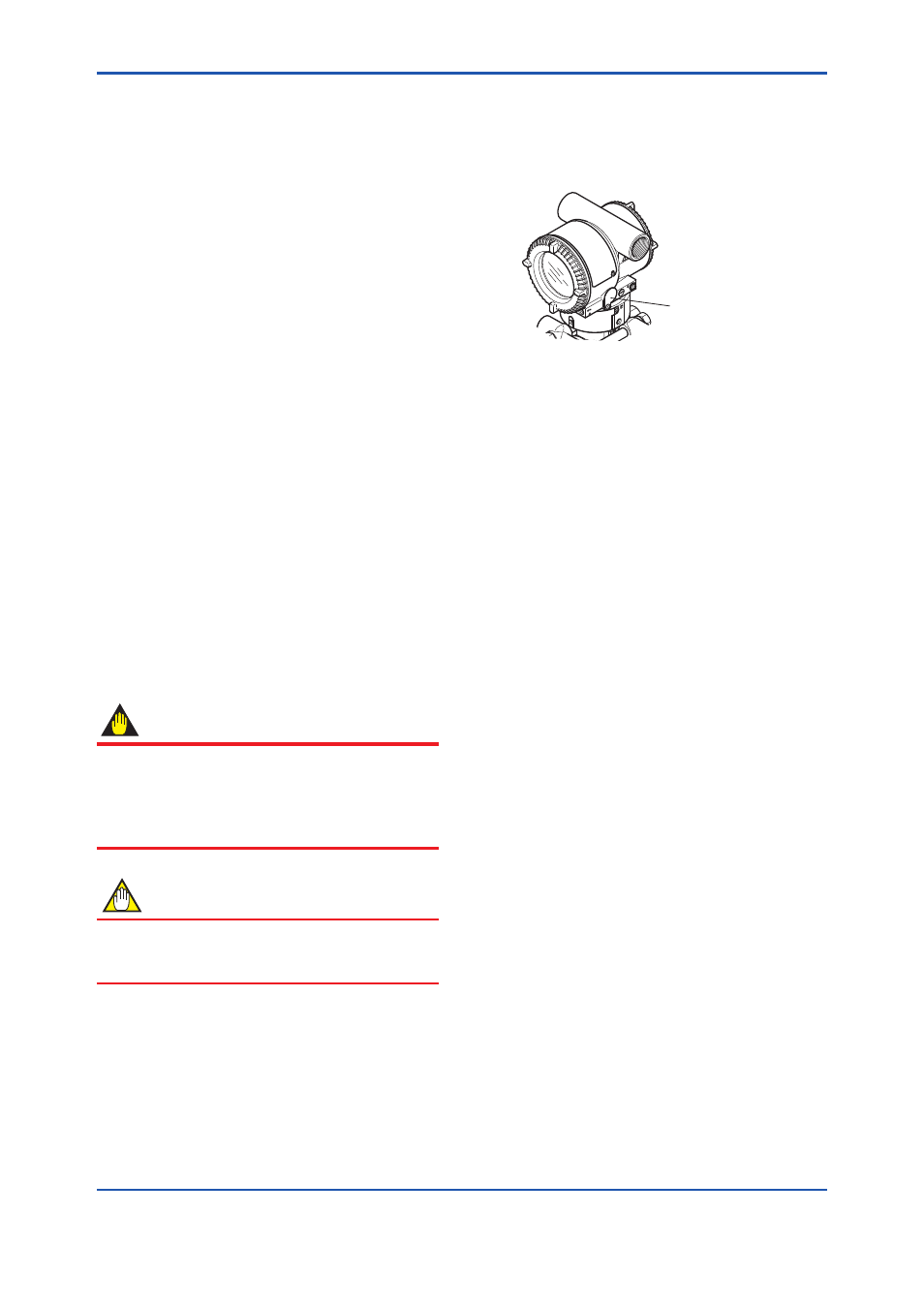

Zero-adjustment

screw cover

F0704.ai

Figure 7.4

External Zero Adjustment Screw

The zero-adjustment screw is located inside the

cover.

Use a slotted screwdriver to turn the zero-

adjustment screw. Equalize the transmitter, then

turn the screw clockwise to increase the output or

counterclockwise to decrease the output. The zero

point adjustment can be made with a resolution

of 0.01% of the setting range. The degree of zero

adjustments varies with the screw turning speed;

turn the screw slowly to make a fine adjustment,

quickly to make a rough adjustment.

7.3 Starting Operation

After completing the zero point adjustment, follow

the procedure below to start operation.

1) Open the stop valve on the upstream side.

2) Gradually open the stop valve on the

downstream side. This places the transmitter in

an operational condition.

3) Confirm the operating status. If the output

signal exhibits wide fluctuations (hunting) due

to periodic variation in the process pressure,

use BT200 to dampen the transmitter output

signal. Confirm the hunting using a receiving

instrument or the integral indicator, and set the

optimum damping time constant.

4) After confirming the operating status, perform

the following.