2 process piping connection examples, Process piping connection examples -2 – Yokogawa EJX115A User Manual

Page 27

<5. Installing Impulse Piping>

5-2

IM 01C25K01-01E

(3) Preventing Freezing

If there is any risk that the process fluid in the

transmitter pressure-sensing assembly could freeze

or solidify, use a steam jacket or heater to maintain

the temperature of the fluid.

F0502.ai

Manifold

Figure 5.2

Manifold Location at the Downside (for

Gas Flow Measurement)

F0503.ai

Manifold

Figure 5.3

Manifold Location at the Upside (for

Liquid Flow Measurement)

5.2 Process Piping Connection

Examples

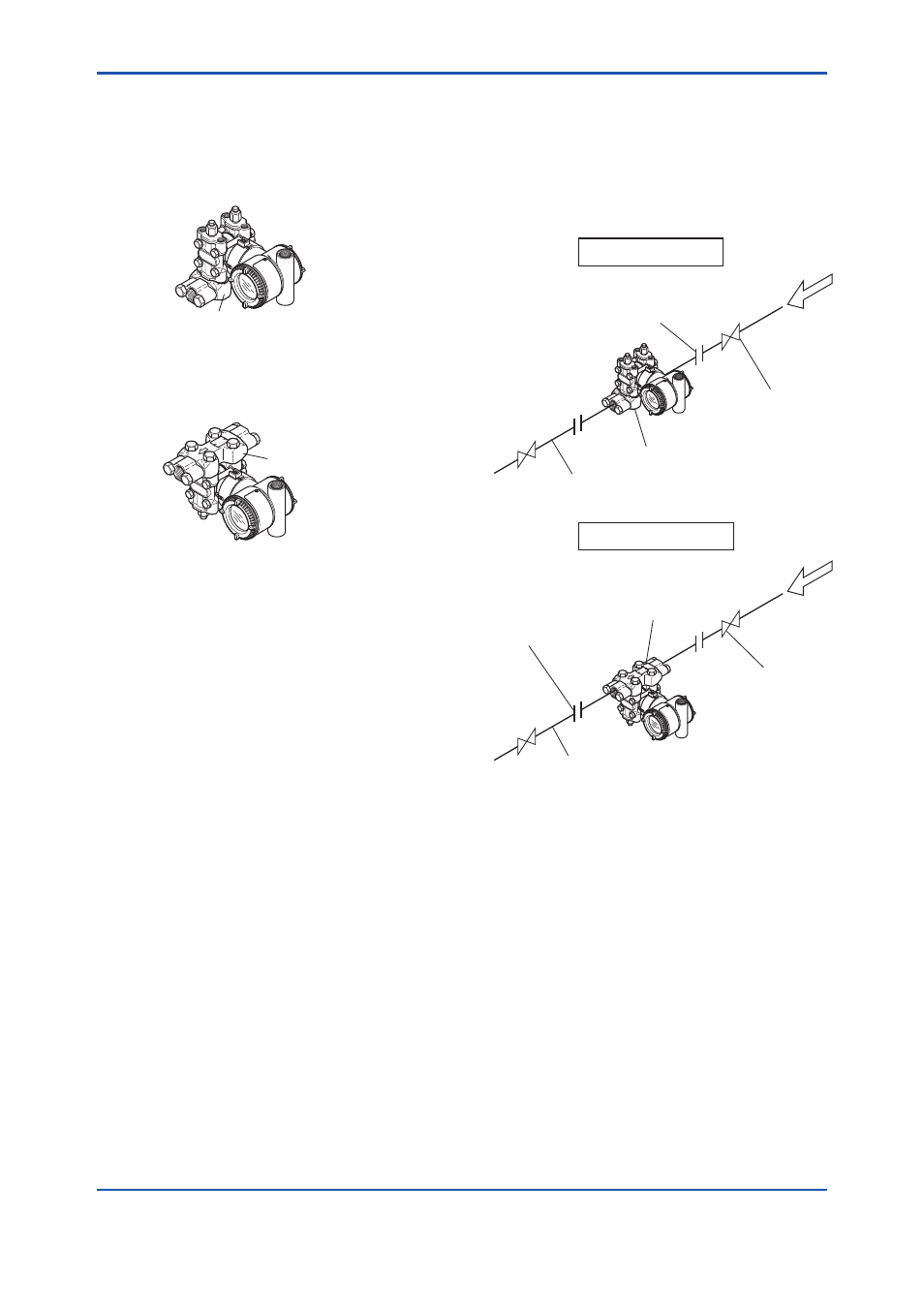

Figure 5.4 shows examples of typical process

piping connections. Before connecting the

transmitter to the process, study the transmitter

installation location, the process piping layout,

and the characteristics of the process fluid

(corrosiveness, toxicity, flammability, etc.), in order

to make appropriate changes and additions to the

connection configurations.

Note the following points when referring to these

piping examples.

• The high pressure connecting port on the

transmitter is shown on the right (as viewed

from the front).

• The transmitter process piping connection is

shown for a vertical impulse piping connection

configuration in which the direction of process

flow is from right to left.

• The process piping material used must

be compatible with the process pressure,

temperature, and other conditions.

• A variety of process piping-mounted stop

valves are available according to the type

of connection (flanged, screwed, welded),

construction (globe, gate, or ball valve),

temperature and pressure. Select the type of

valve most appropriate for the application.

F0504.ai

Gas flow measurement

Liquid flow measurement

Union or flange

Union or flange

Stop valve

Stop valve

Manifold

Manifold

Process piping

Process piping

Figure 5.4

Process Piping Connection Examples