Ramsey Winch DC 34,9 User Manual

Page 18

18

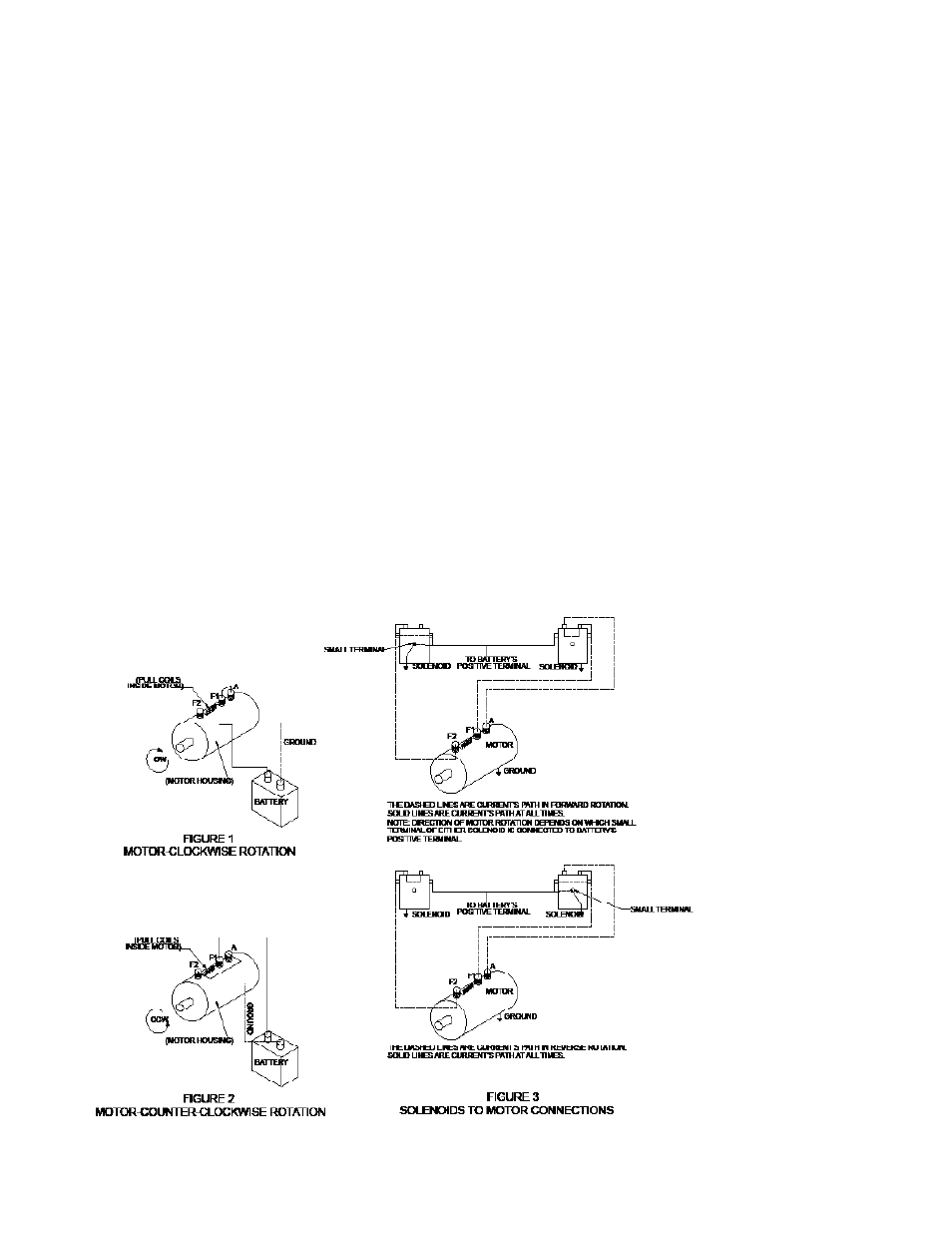

TEST PROCEDURE FOR MOTOR

The Ramsey Winch motor is a (4 pole-4 coil) series

wound 12 volt or 24 volt DC motor.

The 4 pole-4 coil feature provides high torque at low

speeds.

To test the motor to determine if it is functioning properly,

first securely fasten the motor to a bench or work surface

so it will not jump or move around during test procedure

(the starting torque of motor is high).

1. Connect a jumper wire (at least a number 6 wire)

from F-1 to “A” motor terminals (See Figure 1)

2. Attach a wire (at least a number 6 wire) from positive

(+) battery terminal to F-2 motor terminal. Ground

negative (-) battery terminal to motor housing (See

Figure 1). Motor should now run.

To reverse the direction of rotation:

1. Attach jumper wire from F-2 to “A” motor terminals

(See Figure 2).

2. Attach wire from positive (+) battery terminal to F-1

motor terminal. Ground negative (-) battery terminal

to motor housing (See Figure 2).

NOTE: Always attach battery wire solidly to motor termi-

nals. Make and break the connection of the negative (-)

battery terminal at the motor housing. This avoids burning

the motor terminals.

CAUTION: D

O

NOT

RUN

THE

MOTOR

FOR

A

LONG

PERIOD

OF

TIME

IN

FASHION

MENTIONED

ABOVE

,

BECAUSE

THE

MOTOR

COULD

BECOME

DAMAGED

.

The motor running idle on the bench will draw 55 amperes

and must run free and easy. If the ampere draw is more

than 60 amperes and the motor runs rough or has a

strange sound, it should be replaced.

With the motor attached in place on a winch (less cable

on drum) the ampere draw should be approximately 65 to

70 amperes.

If after following the procedure outlined, the test on the

winch significantly exceeds 70 amperes, refer to your

Owner’s Manual for trouble shooting suggestions on the

mechanical portion of the winch.

See Figure 3 for the solenoids connection to the motor

and the battery.