Warner Electric PB-650 Pin Drive User Manual

Page 3

3

Warner Electric • 800-825-9050

819-0485

PB-500 Primary Brake Normal

Duty Pin Drive Armature

Installation Instructions

A. Installing the Conduit Box

Please follow instructions supplied with conduit

box.

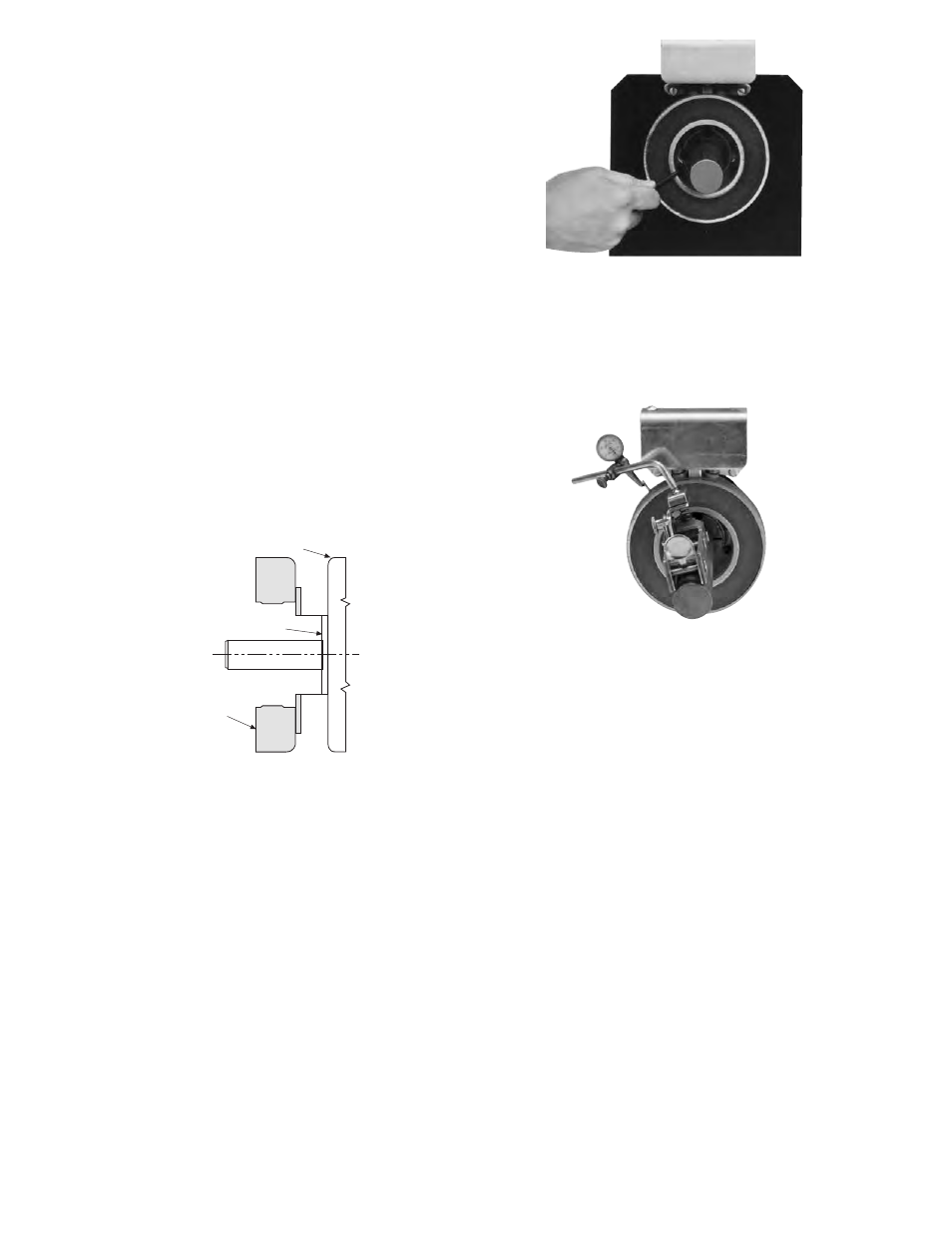

B. Mounting the Magnet

The brake magnet is mounted to a stationary

machine member by a flange. Extreme care

must be taken in selecting the location for the

mounting of the magnet. Proper positioning is

very important for the unit to function correctly.

1. A pilot diameter on the mounting surface is

essential to hold the magnet within the

required tolerances. (Figure 1)

2. A machined pilot diameter is provided on the

magnet mounting flange (refer to illustrations)

to aid in the proper positioning of the magnet.

3. Once the mounting surface has been

prepared, the magnet is bolted in place with

capscrews and lock-washers. (Figure 2)

Mounting Surface

Pilot diameter

Magnet

Figure 1

Figure 2

4. Use a dial indicator to check the unit for

concentricity and squareness to the shaft.

The unit should be concentric within .010

T.I.R. and square within .006 T.I.R. (Figure 3)

C. Assembling the Armature Hub

Assemble the armature to the armature hub with

the autogap mounting accessory. Refer to Figure

4. The hub is reversible. The side on which the

armature is mounted will depend on the direction

in which the taperlock bushing must enter.

The autogap assembly is a double spring device

which allows for automatic armature clearance

and adjustment for wear. The smaller or conical

spring pushes the armature from the rotor face,

leaving the gap of about 1/32 inch, while the

straight spring automatically follows up for wear.

This combination maintains maximum

performance efficiency throughout the life of

the unit.

Figure 3