Warner Electric ARC 2000 User Manual

Page 8

8 Warner Electric • 800-825-9050

P-2016 • ARC

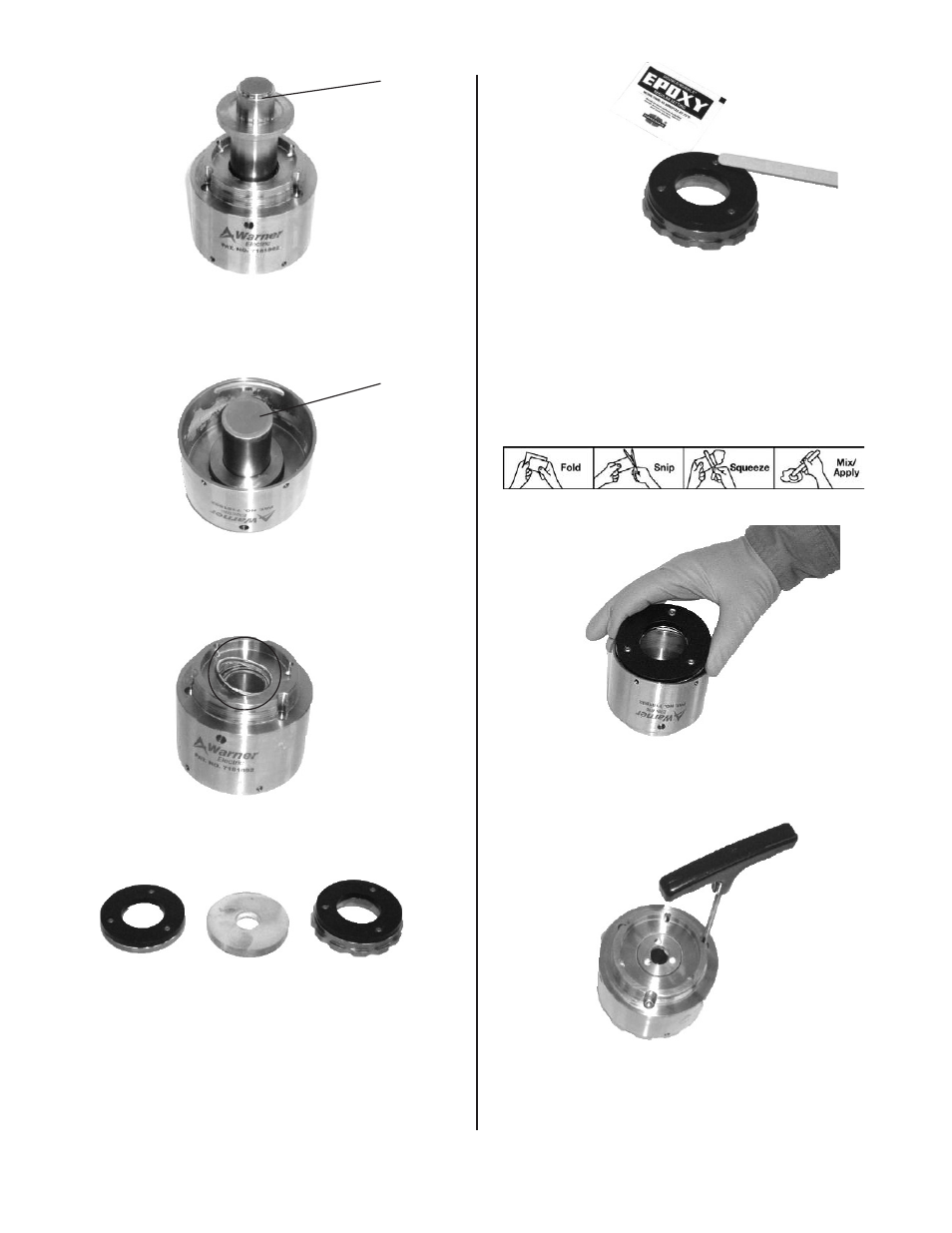

Press bearing out of housing using FIX-0002 and an

arbor press. See FIgure 29.

Figure 29

Turn housing over. Press new bearing in housing

using FIX-0002 and an arbor press. See Figure 30.

Figure 30

Separate magnet stack and clean all magnets –

replace as required. Use an alcohol based cleaning

solvent to clean the black driver magnets. Do not

use anything abrasive when wiping the black driver

magnets. Use a Scotch Brite deburr wheel to polish

the hysteresis magnet. See Figure 32.

Figure 32

Put in new seal. See Figure 31.

Figure 31

FIX-0002

FIX-0002

To replace the magnet on end cap, break the

magnet with a hammer. Remove broken magnet

pieces and old screws. Install new magnet and

new screws. Epoxy magnet holes with epoxy

packet from rebuild kit. Make sure epoxy does

not build up on surface of magnet more than

.010” (0.25mm). See epoxy instructions below

(Figure 34)

Figure 33

Install magnet plate into housing. Line up any

three holes and insert screws. See Figure 35.

Figure 35

Tighten the three socket head cap screws with a

9/64” 3mm hex wrench. See Figure 36

Figure 36

Figure 34

- UNIBRAKE NEMA 4 (6 pages)

- UNIBRAKE (8 pages)

- ARC Clutch_ZRC Top Load (18 pages)

- ZRC Clutch_ARC Top Load (18 pages)

- Dairy Cap Chuck (24 pages)

- Dairy Capping Headsets (10 pages)

- Autogap 475 & 650 (4 pages)

- Brushholder Installation (2 pages)

- Autogap 825-1225 (2 pages)

- Electro-Packs EP-170, 250, 400, 500, 825, 1000, 1525 (20 pages)

- Electro-Brake 375, 475, 650, 825, 1000, 1225 (20 pages)

- Electro-Clutch EC-375, EC-475, EC-650, EC-825, EC-1000, EC-1225 (20 pages)

- 5300-101-001 Collector Ring (2 pages)

- 5301-101-010 Collector Ring (2 pages)

- Brushholder Assembly and Mounting Dimensions (2 pages)

- SF_PB 400 (2 pages)

- SF_PB 250 (2 pages)

- Autogap 825-1525 (4 pages)

- Electro-Module EM-50, EM-100, EM-180, EM-210, EM-215 (22 pages)

- FB-375, 475, 650 (14 pages)

- 5200-101-012 Conduit Box Kit (4 pages)

- 5200-101-011 Conduit Box Kit (4 pages)

- 5200-101-010 Conduit Box Kit (4 pages)

- Recommended Electrical Installation Procedure for Warner Electric Clutches and Brakes (2 pages)

- EP-400 Vertical Mounting (2 pages)

- EP-250 Vertical Mounting (2 pages)

- Autogap 500 (4 pages)

- ER 825 and 1225 Normal Duty (16 pages)

- ER 825 and 1225 Heavy Duty (14 pages)

- ERS Electrically Released Brakes (6 pages)

- AT Brakes & Clutches Complete Brake Repair – On the Shaft, Sizes 25, 55, 115 (4 pages)

- AT Brakes (6 pages)

- AT Brake–Major Service Repair Instructions for Sizes 25, 55, 115 (9 pages)

- AT Clutch – Major Service Sizes 25, 55, 115 (12 pages)

- 5162-101-002 Conduit Box Kit (6 pages)

- Electrically Released Permanent Magnet Clutch Compatible Modules (4 pages)

- Electrically Released Motor Brake Module for EM-MBFB and EUM-MBFB (6 pages)

- Electrically Released Brake Module For EM-FBB and EUM-FBB (4 pages)

- Electrically Released Brake ER-375, ER-475, ER-650 (12 pages)

- Autogap 825-1525 Special Heavy Duty (4 pages)

- 5370-101-042 Conduit Box Kit (4 pages)

- Preassembled Clutch_Electrically Released Brake Module (7 pages)

- EUM-50_EUM-100_EUM-180_EUM-210_EUM-215 (16 pages)

- 5370-101-045 Conduit Box Kit (5 pages)