Setting application torque, Recommended maintenance schedule – Warner Electric ARC 2000 User Manual

Page 4

4 Warner Electric • 800-825-9050

P-2016 • ARC

Setting Application Torque

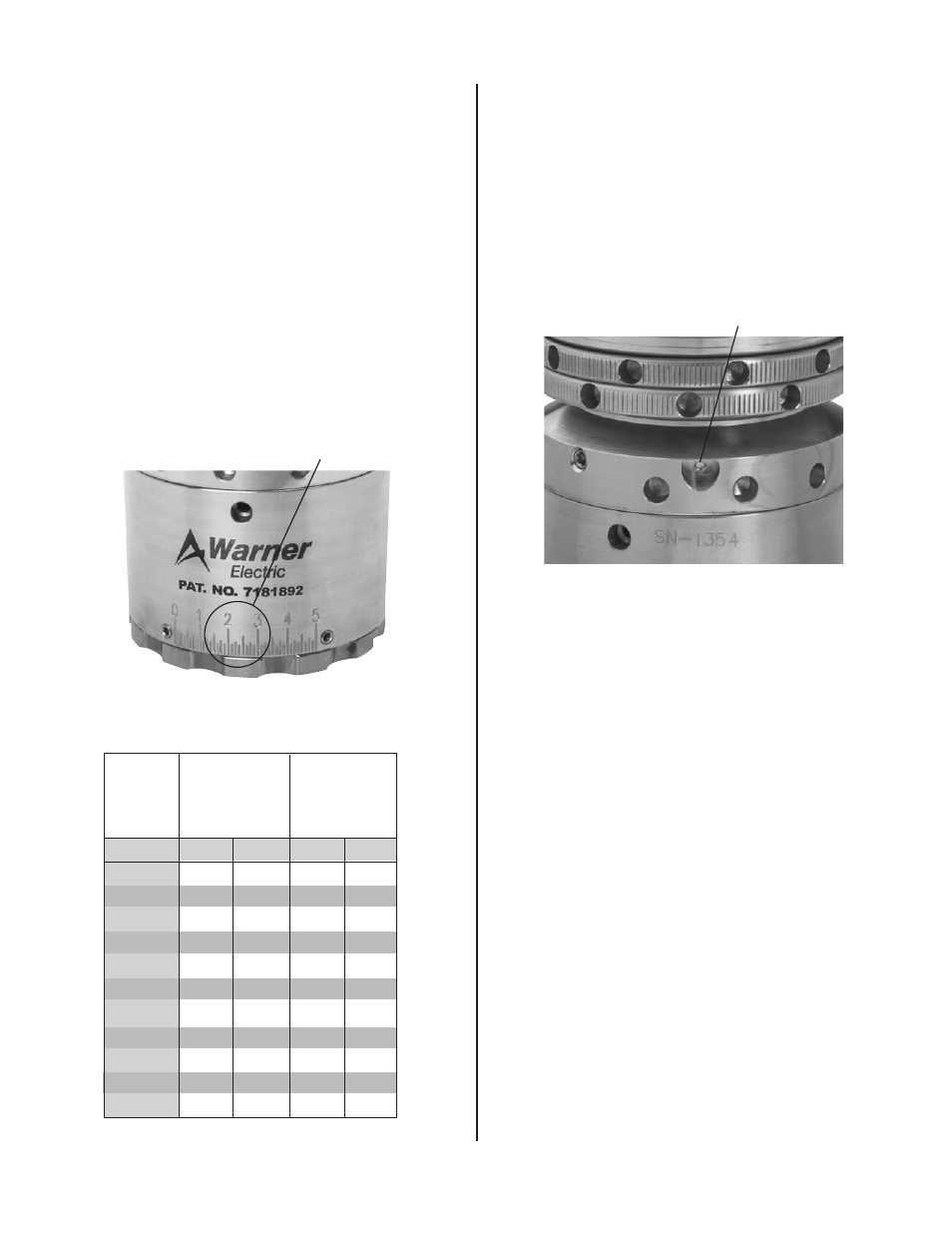

1. Determine initial clutch setting from torque chart

below.

2. Loosen the torque adjustment screws. Rotate the

adjustment ring using the face spanner wrench to

the desired setting and then retighten the torque

adjustment screws. Do not use the set screw in

the slot on the backside of the housing for torque

adjustment. Tighten set screws to 8-10 lb-in.

Over tightening is not necessary and will strip the

screws or possibly damage the housing body.

3. For optimum results, check setting with a torque

wrench and FIX-0007 or FIX-0010.

Application

Torque Setting

Application Torque Setting Charts

Clutch

Setting

Application

Torque-Low

Inertia

Magnet

Application

Torque

(Ncm)

Standard

Magnet

lb-in Ncm lb-in Ncm

0.00

2.00

22.5

2.5

28.2

0.50

3.50

39.5

4.0

45.2

1.00

5.00

56.5

5.0

56.5

1.50

8.50

96.0

8.5

96.0

2.00

10.50 118.6 11.0 124.3

2.50

13.50 152.5 15.0 169.5

3.00

16.00 180.7 18.5 209.0

3.50

17.50 197.7 22.0 248.5

4.00

18.50 209.0 24.0 271.1

4.50 19.00 214.6 25.5 288.1

5.00 19.50 220.3 26.0 293.7

Recommended Maintenance

Schedule

Lubricate the upper assembly every 500

hours of run time.

- Using a grease injector needle, apply lubricant

into the grease port.

- Recommended grease: No. 2 Food Grade

Grease

Grease Port

Disassemble, clean, and replace all wearing

parts in the headset every 7000 hours of

machine run time.

- See rebuild instructions for detailed information

on disassembly and assembly of Warner

headsets.

- Dependent upon machine speed and

washdown procedure, some environments

may require more frequent rebuilds.

Figure 7

Figure 8

Rebuild Kits available:

•

M4.5-BK (Bearing and Hardware Rebuild Kit)

•

M4.5-MK (Magnet Rebuild Kit)

•

M4.5-PK (Push rod Rebuild Kit)

•

M4.5-TL (Replacement Top Load Assembly)

*Contact customer service for the exact kit part

number for your specific headset model.