Usage instructions (continued), Blockage prevention – Vestil CC-30-MC User Manual

Page 50

49

Help Line: 800-363-2488

October 15

th

, 2001

USAGE INSTRUCTIONS (continued)

BLOCKAGE PREVENTION

In the event of a chute blockage, the chute system could

tear away from the building causing serious injury or

death. To prevent blockages follow these guidelines:

• Ensure falling debris can be seen to exit the chute and

enter the container (see the sketches on the left).

• Make sure the chute is hanging straight (vertically).

Horizontal displacement of the chute must not exceed

20% of the height. Have the chute reinstalled if it does

not meet this criteria.

• Make sure the chute is not bent over balconies, shelves,

or similar structural protrusions. These obstructions

could crimp the chute and lead to a blockage. Have the

chute reinstalled if it is bent or crimped.

• Only introduce debris with dimensions that are less

than half the diameter of the chute. For example: if

using a 30” (76 cm) diameter chute, the maximum

allowable dimensions of the debris are 15” x 15” x 15”

(38 cm x 38 cm x 38 cm).

• Do not use motorized loaders to introduce debris into

the chute (motorized loaders introduce too much debris,

too quickly).

• Break-up debris before throwing it into the chute.

• Move the discharge end around the container to prevent

it from clogging as the container fills.

• Inspect the chute for blockages frequently.

• Designate a safety monitor who will, in addition to

monitor for blockages, supervise the safety of the entire

debris removal operation.

• Use load cells to monitor the chute weight and detect

blockages (see

page 42

for more load cell information).

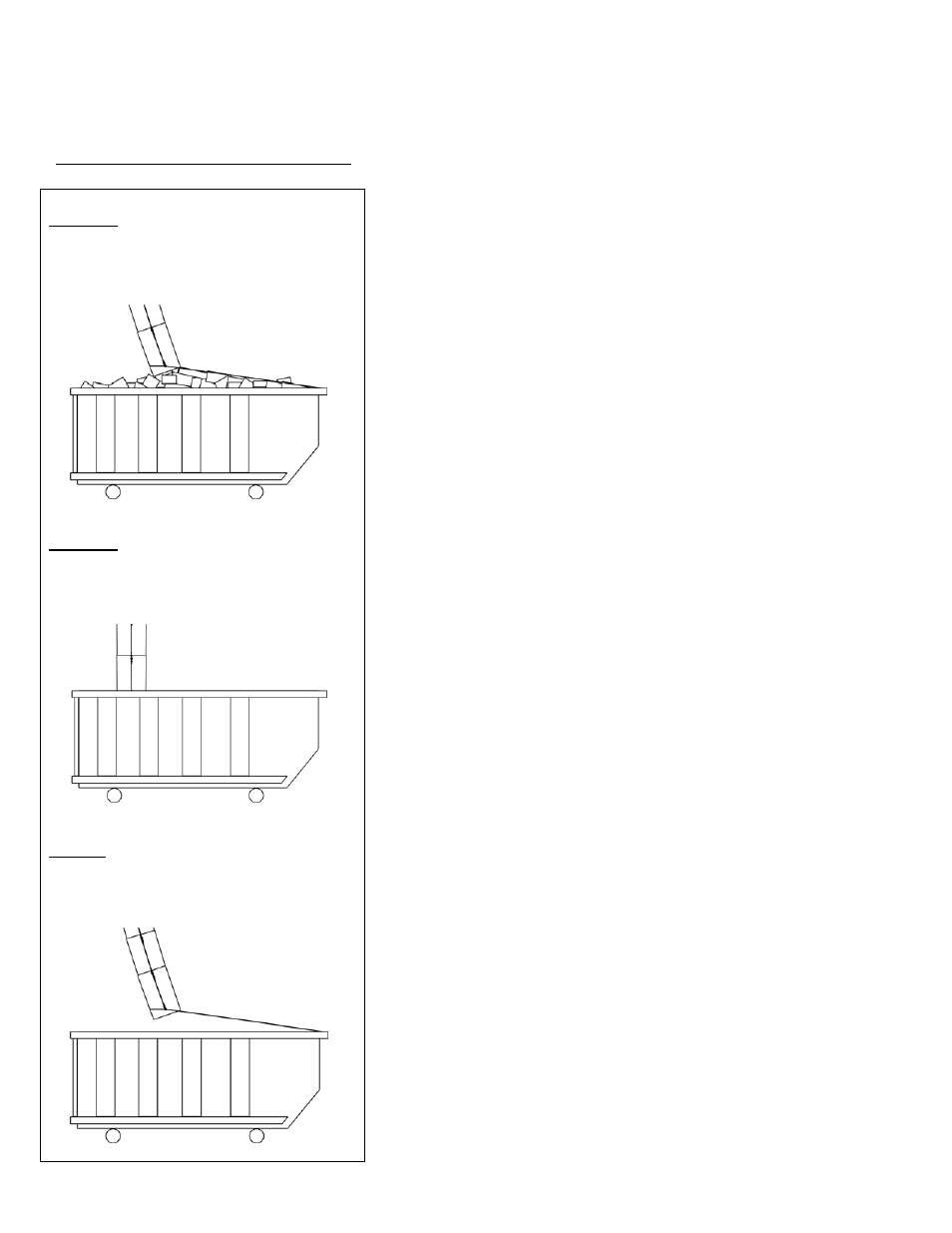

WRONG

Falling debris cannot be seen to exit the

discharge end of the chute. This situation

prevents blockages from being noticed.

RIGHT

Falling debris can be seen to exit the

discharge end of the chute and enter the

container.

WRONG

The container is overfilled. This could

cause the chute to fill from the bottom and

collapse. Do not overfill the container.