The cable assembly (continued), Wire rope chain – Vestil CC-30-MC User Manual

Page 12

11

Help Line: 800-363-2488

October 15

th

, 2001

THE CABLE ASSEMBLY (continued)

WHY IS WIRE ROPE USED IN THE CABLE ASSEMBLY?

"For general construction rigging never use a chain when it is

possible to use wire rope. The failure of a single link of chain can

result in a serious accident but wire rope on the other hand is

frequently composed of 114 wires, all of which must fail before the

rope breaks. Wire rope gives you reserve strength and a chance to

notice a hazard, chains do not."

Rigging Manual, CSAO, 1996

There are many advantages to wire rope:

Wire Rope

Chain

Provides warning when worn

No visible warning before failure

Consistent strength

Inconsistent strength – except the high quality grades

Lightweight

Heavy and bulky

The many strands create a multiple

point suspension system

Single point suspension: Lose a link – lose it all.

Chain is only as strong as its weakest link.

Occasionally Superchute

®

will use chain in cases where adjustment is required. For

example: Door Adjustment Kits and chute hoists. However, only high quality Grade

70 and Grade 80 chains are ever used.

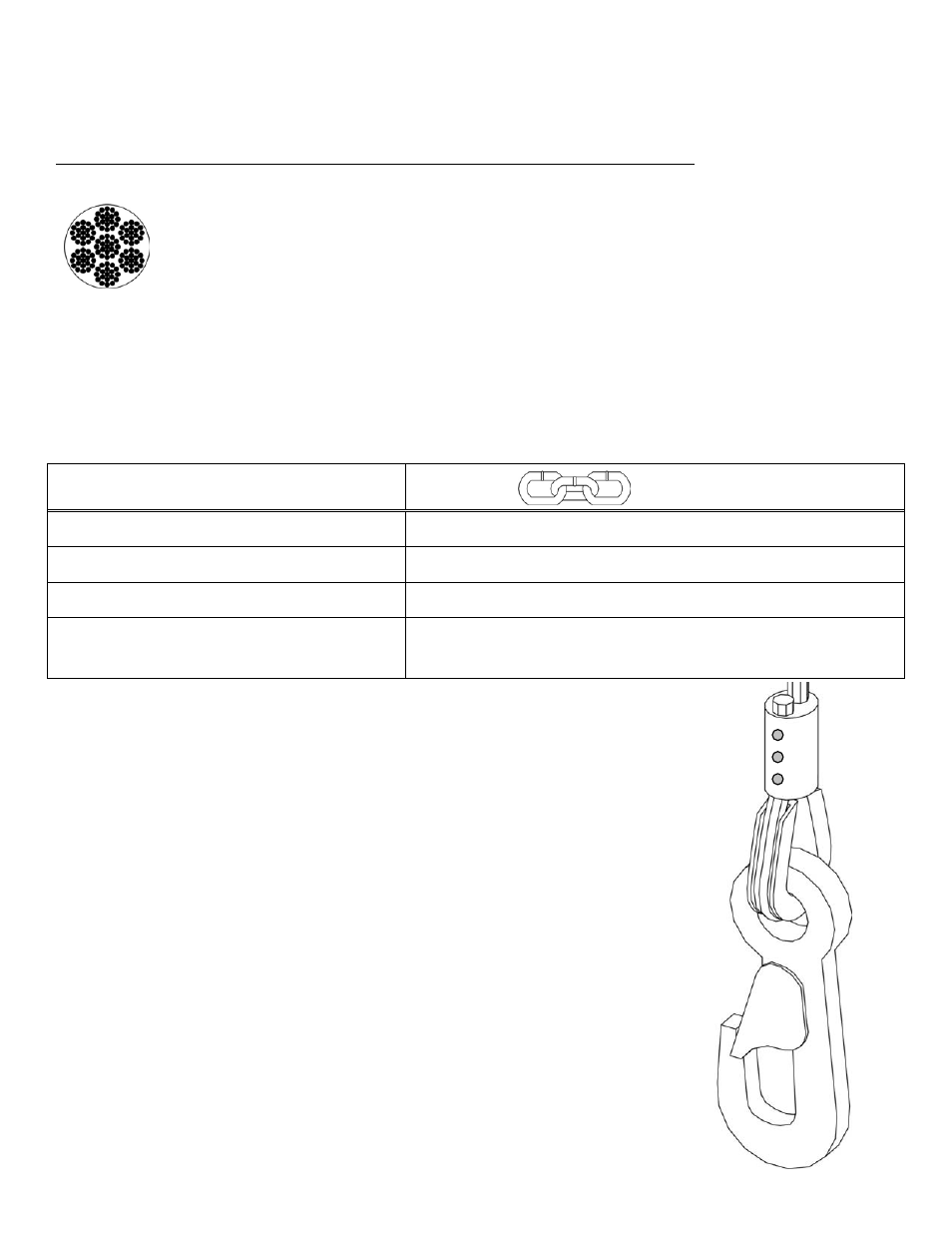

The three dots on the pressed sleeve

are Superchute’s

®

identifying mark.

This mark has been in effect since

March 1998.

Close up view of the forged clip used

on cable assemblies since June 1996.

Cross sectional

view of a wire

rope