Modifying gravers, Holding the powergraver handpiece, Determining the length of the graver or tool – Foredom Safety Instructions for Using User Manual

Page 3: Adjusting impact

tightened.) The shank of the tools should

be at least 1

″ (25mm) long so that it will

make contact with the bottom of the

collet holder. This is important because

it maximizes the hammering action

efficiency and the tool will not “slip back”

in the collet.

Insert the tool or graver into the collet

until it touches the bottom of collet

holder, then tighten the chuck nut

securely with one wrench while holding

the collet holder shaft with the other. Do

not tighten chuck nut without using a

wrench on the flats in collet holder shaft.

Failure to use both wrenches can damage

the handpiece.

Retighten the chuck nut periodically as

you work since extended use may loosen

the chuck nut.

Modifying Gravers and

Other Tools To Fit the

Handpiece Chuck –

Modifying tools to fit securely in the

handpiece chuck is not difficult. The shank

or tang end of the tool must be ground or

cut so that it is at least 1

″ (25mm) long

and 1/8

″ (3mm) or less in diameter.

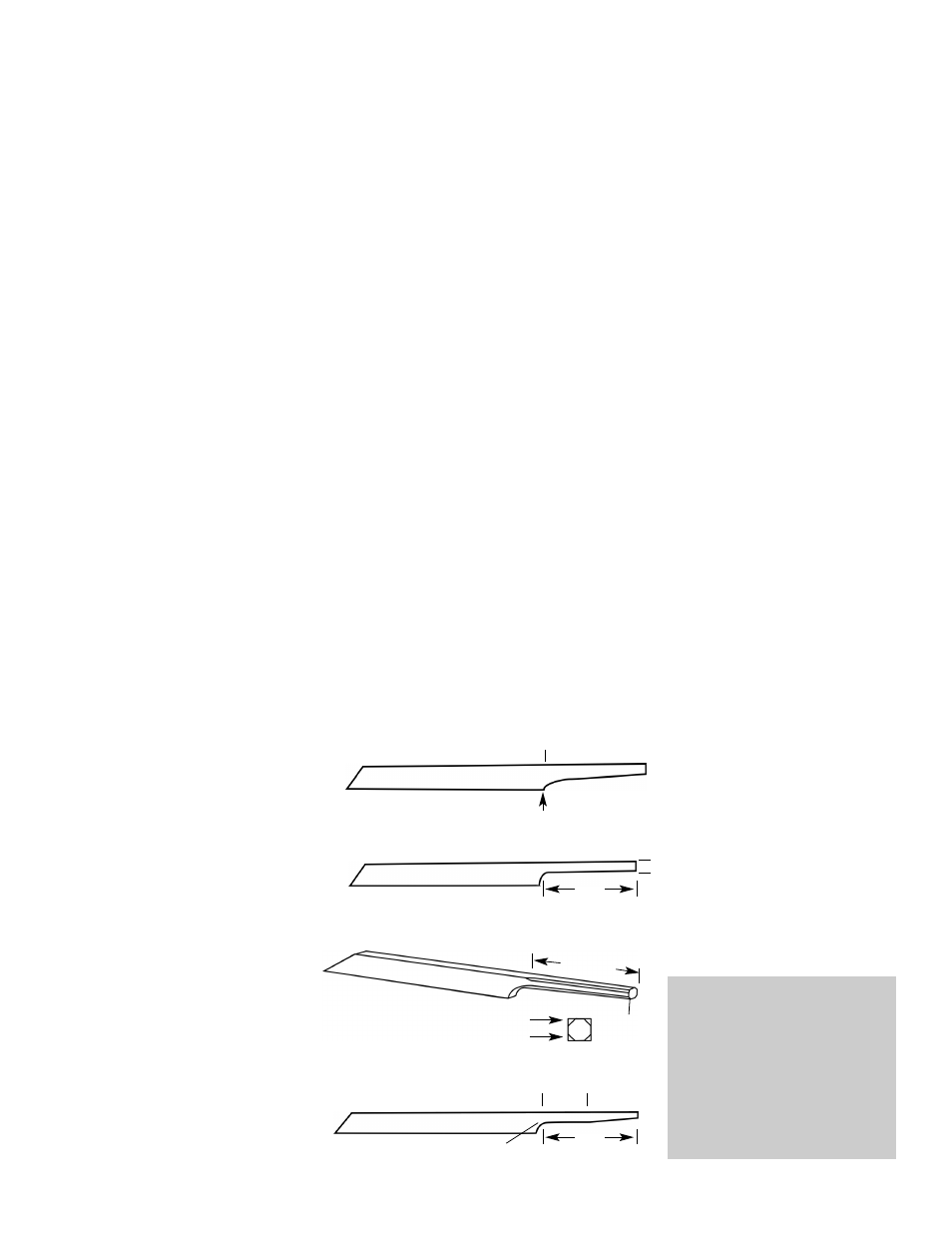

Modifying Gravers –

The tapered tang on the traditional style

gravers need to be ground as shown in

Illustration 3. A new graver’s tapered tang

(Fig. A) can be ground with a bench

grinder or grinding wheel in a flexible

shaft handpiece until it is straight (see

Fig. B) and 1

″ (25mm) long and 1/8″

(3mm) wide. Then grind the corners off

(see Fig. C) making it as round

as possible.

If the taper is less than 1/8

″ (3mm)

at the end of the tang, grind a 1/2

″

(12.5mm) long section (see Fig. D)

behind the heel into a 1/8

″ (3mm)

diameter. This is the section held

by the handpiece collet jaws.

For smaller gravers and tools, grind the

tang or shank end to a 1

″ (25mm) long

by 3/32

″ (2.35mm) or 1/16″ (1.6mm)

diameter for use in the smaller collets.

Try to keep the 1

″ long section in line

with the top, bottom and sides of the

graver as much as possible for better

control of the cutting edge. Remove all

burs or sharp edges on the tang or

shank end to prevent damage to the

collet or inside of the collet holder.

Holding the PowerGraver

Handpiece –

Because the PowerGraver is designed to

help the jeweler or engraver with bead

setting, bright cutting and engraving,

the handpiece should be held like a

conventional graver. Hold the handpiece

by placing your hand, palm down, over

the top of the handpiece. Locating the

adjustable palm rest in the center of your

palm, extend your thumb to the left side

of the chuck nut, put your index finger to

the right side or on top of the chuck nut.

Your other fingers can go around the palm

rest until they rest on the flat underside of

the palm rest. This is a very natural and

comfortable position to hold the

handpiece, similar to holding a regular

graver. The only time the handpiece would

be held like a pencil would be when using

it for applying a texture finish or doing

channel setting.

Determining the Length

of the Graver or Tool –

Having the graver or tool at a comfortable

length from the chuck is very important. A

graver that is too long feels awkward and

is difficult to control. To determine a

workable graver length first insert a

graver with the tang end modified into

the collet. Then, place the handpiece in

your hand as suggested above. Extend

your thumb along the length of the graver

blade while still holding the handpiece

comfortably in your hand. Mark the graver

at about 3/4

″ (19mm) past the end of

your thumb. This is the length where the

graver should be to provide an efficient

working length.

The palm rest can also be adjusted for-

ward about 1/4

″ (6mm) to accommodate

a longer graver and moved back up the

grip as the graver becomes shorter from

repeated sharpening.

To shorten a graver use the corner of a

bench grinding wheel to first grind half

way through one side of the graver where

marked. Then grind most of the way

through the other side of the graver until

it is thin enough to snap off after placing

it in a bench vice.

Adjusting Impact –

Turning the impact adjustment ring

(page 2, Illustration No. 2) to the right

(clockwise) will reduce or soften the

impact. Turning it to the left (counter-

clockwise) will increase the impact

force. The ring can be rotated while

the motor and handpiece are running

so that you can “feel” and “hear” the

change in impact.

Section held

by collet

Illustration No. 3

Fig. A

Fig. B

Fig. C

Fig. D

Tang

Heel

1

″

(25mm)

1

″

(25mm)

1

″ (25mm)

1/8

″

(3mm)

1/8

″

(3mm)

Remove all

four corners

1/8

″ (3mm)

Holding the Power Graver Handpiece

and Determining Best Graver Length

Helpful Hint For even lighter

impact when doing very delicate

work or to avoid damaging small

stones when doing setting work,

grab the chuck nut with your thumb

and index finger and pull back

slightly while handpiece is running.

This will reduce or “cushion” the

impact even more

.

3