Foredom H.56D User Manual

Important instructions

Instructions for Handpieces H.55A, H.56A, H.55D, and H.56D

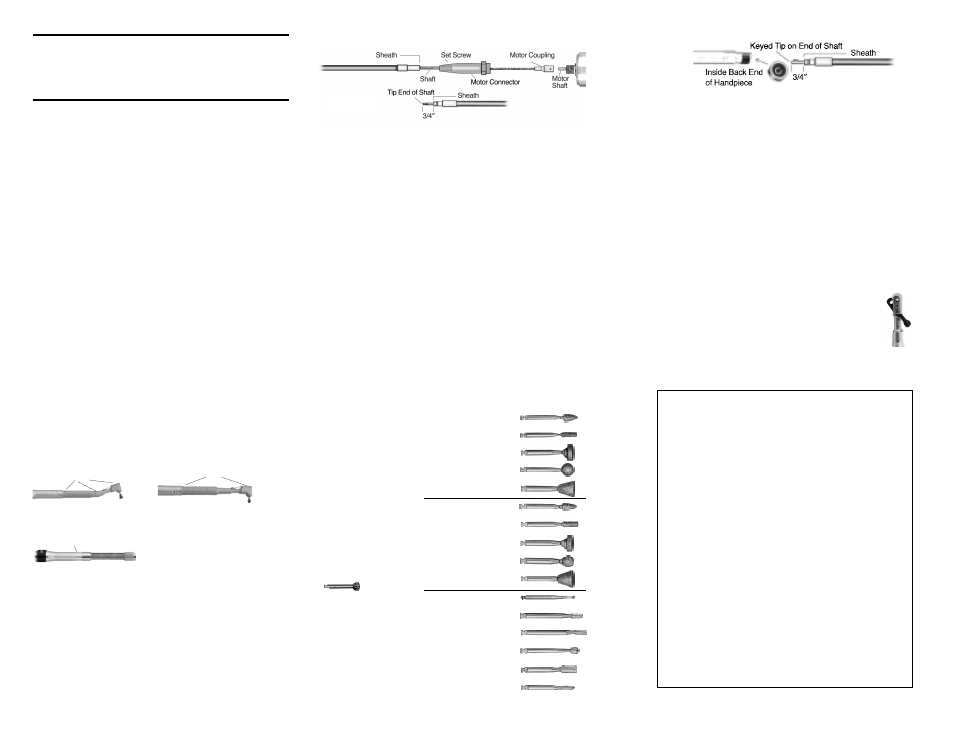

Shaft and Sheath Adjustment

It is important to check the sheath and shaft tip and properly adjust

them before you attach this handpiece to your Foredom flexible shaft

tool. The tip of the flexible shaft should extend 3/4

″ beyond the end

of the sheath and no more than 7/8

″ or less than 5/8″ (see Figure 1).

On Foredom machines with standard shaft and sheath, this

adjustment is made by loosening the set screw in the motor connector

and moving the sheath in or out while the motor and shaft/sheath

assembly are fully extended and straight while hanging or on a flat

surface. When the correct adjustment is made, tighten the set screw in

the motor connector.

For More Information:

For more information on Foredom machines, handpieces,

or accessories, contact your local dealer. If no local dealer is

available, contact: The Foredom Electric Company,

16 Stony Hill Road, Bethel, CT USA 06801,

tel.: 203-792-8622, fax: 203-796-7861

e-mail: [email protected], or visit our web site:

www.foredom.com.

Always wear proper eye protection

while using this handpiece.

Form 1254 n 5/08

Printed in USA

Please read instructions before

attaching this handpiece.

See your power tool owner’s manual for complete

instructions on use, care, and maintenance.

IMPORTANT INSTRUCTIONS

Foredom

®

Handpieces H.55A, H.56A, H.55D,

and H.56D

LIMITED WARRANTY

The Foredom Electric Co. warrants its product to be free of defects

in material or workmanship for a period of 90 days after purchase.

During the warranty period, the defective product will be repaired or

replaced without charge or, at our option, the purchase price will be

refunded. This warranty does not cover damage caused in transit or

by accident, misuse, or ordinary wear. ALL IMPLIED WARRANTIES,

INCLUDING BUT NOT LIMITED TO WARRANTIES OF FITNESS AND

MERCHANTABILITY, ARE HEREBY LIMITED IN DURATION TO A

PERIOD ENDING 90 DAYS FROM DATE OF PURCHASE, AND WE

WILL NOT BE LIABLE OR RESPONSIBLE FOR ANY SPECIAL OR

CONSEQUENTIAL DAMAGES. Repair or replacement will be made

at our option if the product is returned post-paid to:

The Foredom Electric Company

16 Stony Hill Road, Bethel, CT USA 06801

All warranty repairs must be done at the factory at the above

address. We will not pay any shipping or transportation charges.

The HP76 Duplex Spring is not covered by this warranty since it is

especially sensitive to the pressure and stress variables of each

individual operator. This warranty only covers the original purchaser

of the product. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitations may not apply to

you. This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note: This illustration

does not apply to slip

joint connections.

Figure 1

Figure 2

Attaching the Handpiece to Flexible Shaft

Attach the handpiece by pushing it on the grooved QD (quick

disconnect) fitting on the sheath. Be sure that the keyed tip of the

flexible shaft is properly lined up with the slot in the handpiece shaft

connector by looking into the rear of the handpiece before pushing

it on. If it is not in line, turn the handpiece to the correct position.

Operation and Use

Foredom angle handpieces contain small right angle gears in their

heads. The H.55A and H.55D also have gears in the front portion of

the handpiece body. the teeth on these gears can be stripped if

excessive pressure is applied to the accessory. let the speed of the

accessory, not pressure do the work. Do not use grinding stones or

discs over 3/4

″ in diameter. These handpieces are intended for

doing intricate, light duty work in hard to reach spots. To reduce

risk of spring breakage or overheating, avoid using a sharp bend in

the duplex spring connection in the H.55D and H.56D handpieces.

Attaching Latch-type Accessories

Push the latch in the head of the handpiece to the right

to open and insert accessory. Push latch to the left to

lock the accessory. (Right and left are defined as you

face the back of the handpiece head.)

left right

A-M-10 Mandrel

3/32

″ dia. shank

1/16

″ arbor hole

7/8

″ long

A

lu

m

in

u

m

O

x

id

e

(R

e

d

)

S

il

ic

o

n

C

a

rb

id

e

(G

re

e

n

)

V

a

n

a

d

iu

m

S

te

e

l

Latch Type

Accessories for

Angle Handpieces

H.55A, H.55D,

H.56A, and H.56D

Standard

Latch Type Mounted

Abrasive Points

and Steel Burs

Maximum

Speed Rating

35,000 RPM

Part

No.

A-RA1

A-RA3

A-RA11

A-RA12

A-RA21

A-RA31

A-RA33

A-RA41

A-RA42

A-RA51

A-RA11R

A-RA44

A-RA62

A-RA88

A-RA563

A-RA850

Head

Dia.

1/8

″

3/32

″

1/4

″

3/16

″

1/4

″

1/8

″

3/32

″

1/4

″

3/16

″

1/4

″

7/64

″

3/64

″

5/64

″

3/32

″

5/64

″

3/32

″

Head

Length

1/4

″

9/32

″

7/64

″

3/16

″

5/16

″

1/4

″

9/32

″

7/64

″

3/16

″

5/16

″

7/64

″

13/64

″

15/64

″

7/64

″

15/64

″

15/64

″

Maintenance and Lubrication

It is important to regularly lubricate the gears and spindle of

the 55A and 56A. The 55D and 56D require lubrication of the

gears, spindle, and duplex spring connection drive axle.

Apply one drop of Foredom handpiece oil (P/N MS10005) in

oil holes shown below every one hour of continuous use.

oil

H.55A/H.55D

H.56A/H.56D

Duplex Spring Connection

oil

oil

For more information, request:

Handpiece Parts Lists

H.55A/H.55D —Form No. 1140

H.56A/H.56D —Form No. 1141