Maintenance and assembly, Operation, Lubrication – Foredom K.500 User Manual

Page 2: Shaft replacement, Adjustment of shaft and sheath, Set up, H.60 massager handpiece maintenance

Operation

For the best performance, safety, and

maximum life, please follow these

general suggestions:

1. Try to avoid using the Massager with

sharp bends or loops in the flexible shaft.

This will reduce wear of the flexible shaft

and the sheath lining.

2. Never deliberately stall the motor or slow

it down near the stalling point by bearing

down too hard on the handpiece.

3. The Massager comes with a dial control

built into the base. Strokes can be varied

from 0 to 4,400 per minute with the turn

of the dial.

Maintenance and

Assembly

These simple maintenance procedures

should be done by the user:

1. Cleaning and lubrication of flexible shaft

and handpiece.

2. Replacement of motor brushes.

3. Replacement of worn shafts

and sheaths.

4. Replacement of handpiece pads.

Keep the Massager as free of dust and

dirt as possible. Never allow oil or

grease to accumulate on exposed

surfaces as this tends to collect dirt.

Lubrication

The motor has permanently lubricated bear-

ings and does not require lubrication.

The flexible shaft should be cleaned and

lubricated once every 100 hours of use.

Expose the shaft by removing the handpiece

and then the sheath by loosening the set

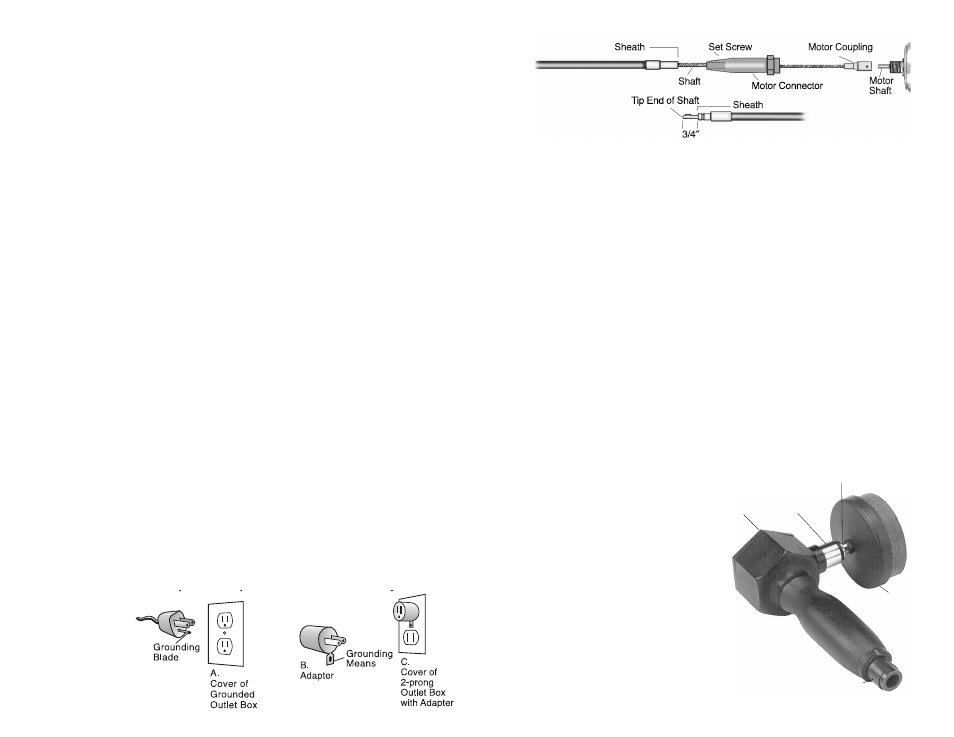

screw in the motor connector (see Figure 1)

and sliding it off the shaft. Apply a light film

of Foredom flexible shaft grease (MS10006)

along the entire length of the shaft after wip-

ing off the old grease with a piece of cloth.

Replace the sheath by sliding it over the shaft

and tightening the set screw. Be sure to

follow the Adjustment Instructions below.

Shaft Replacement

1. Remove the motor connector. Left hand

thread, turn right. (See Figure 1)

2. Loosen the set screw on the old flexible shaft

motor coupling and slide the shaft coupling

off the motor shaft. (See Figure 1.) Tighten

the set screw of the new shaft onto the flat

on the motor shaft.

3. Put the motor connector back on the motor

by sliding it up the flexible shaft and tighten-

ing. Grease shaft as described above.

4. Now slide the sheath over the flexible shaft

with the plain sheath fitting (not the grooved

fitting) going toward the motor and into the

motor connection.

Adjustment of Shaft and Sheath

Before attaching handpiece, shaft and sheath

adjustment must be carefully checked. Place

the entire unit on a flat surface with shaft and

sheath extended straight. Adjust the exposed

tip of the flexible shaft so that it extends 3/4

″

beyond the sheath, as shown above. This is

done by moving the sheath in or out of the

Front

Plate

Set Screw

Adjustment

Sleeve

Plunger Shaft

Handpiece

Pad Holder

Figure 1

Figure 2

Set Up

Check the voltage of your power before

plugging in the motor. It should match the

voltage shown on the motor nameplate.

Models 500 and 500L are for use on 115

Volt AC power. Models 500-2 and 500L-2

are for use on 230 Volt AC power.

Note: The Massager Handpiece comes

attached to the motor. If you need to remove

the handpiece (when cleaning, for example),

loosen the set screw and just pull away from

the shaft and sheath with a strong motion.

To reattach, push the handpiece onto the

shaft tip and sheath fitting while motor is

running slowly. Be sure that the catch ball in

the end of the handpiece toward the sheath

goes into the groove in the sheath tip so

that the handpiece will be held securely onto

the sheath.

motor connector. When the correct adjust-

ment is made, tighten the screw in the motor

connector. The handpiece can now be

reattached as described in the Note: under

“Set Up”.

H.60 Massager Handpiece

Maintenance

The handpiece should be cleaned and

lubricated once every 100 hours of use.

Remove the Front Plate to expose the

eccentric cam and plunger shaft. Flush out

the old grease with a solvent and regrease

with a teaspoonful of Foredom grease,

being sure that all the moving parts are

thoroughly lubricated. After regreasing, run

the handpiece slowly for a few minutes to

fully distribute grease. The Adjustment

Sleeve retains a grease seal and should be

tightened to prevent leakage of grease.

•

Use proper grounding procedures. This tool

should be grounded while in use to protect

the operator from electric shock. The tool is

equipped with an approved 3-conductor cord

and a 3-prong grounding type plug to fit the

proper grounding receptacle. The green (or

green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or

green and yellow) wire to a live terminal. If

your unit is for use on less than 150 volts, it

has a plug that looks like sketch A below. An

adapter (sketches B and C) can be used for

connecting plugs as shown in sketch A to

2-prong receptacles. The green colored rigid

ear, lug, etc., extending from the adapter must

be connected to a permanent ground such as

a properly grounded outlet box.

Some jurisdictions, including Canada,

prohibit the use of 3 to 2 prong adapters.

Where prohibited, they should not be used.

Use only 3-wire extension cords that have 3-

prong grounding type plugs and 3-pole type

plugs and 3-pole receptacles that accept the

tool’s plug. Always disconnect the power cord

before servicing the tool.

Replace a worn

cord immediately.

Models 500-2 and 500L-2 are equipped

with power plugs suitable for use in the

country for which they are intended.