Operation, Bench lathe attachments – Foredom BL User Manual

Page 3

Operation

Because of the higher maximum speed

(approximately 7,000 RPM) and variable

speed control, the Foredom

®

Bench Lathe

has several advantages over conventional

single or two speed polishing and

buffing lathes:

1. The same size buffing wheel can

be used to obtain different surface

speeds, as measured in surface feet per

minute (SFPM). 3

″ or 4″ diameter buffs

can provide the 1,750 to 3,450 SFPM

recommended for polishing and the

3,450 and higher SFPM recommended

for buffing. The chart below shows the

SFPM obtained with different diameter

wheels at various speeds.

2. The SFPM can be varied while using the

same diameter buff or wheel. This will

give better results on different types

of material.

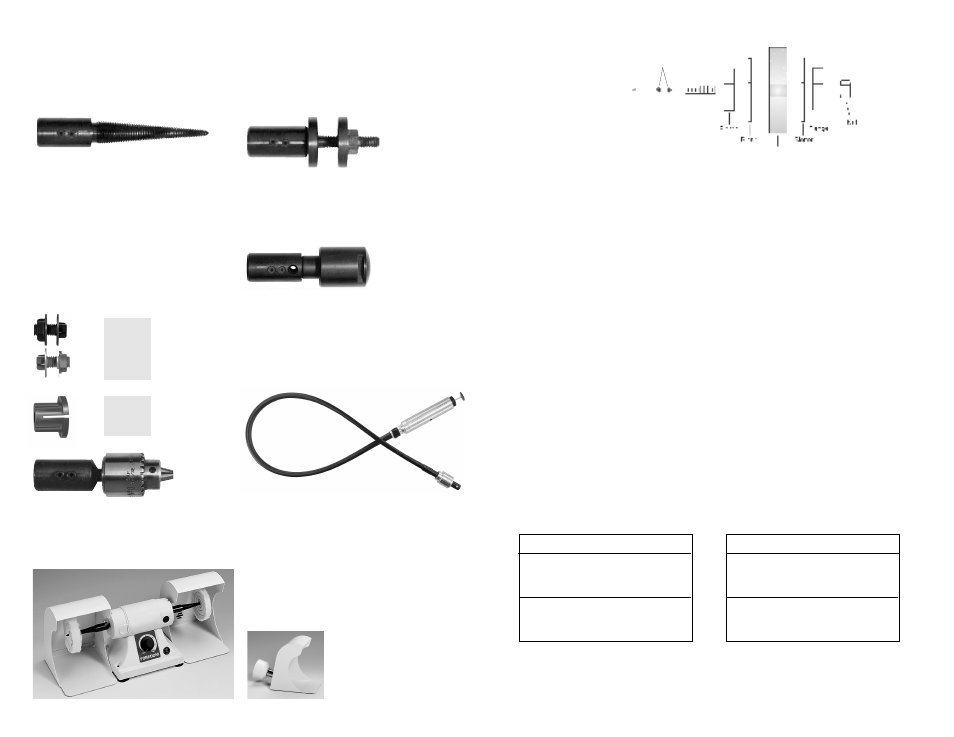

Figure 2

A-WM-6 Assemble

all components in

proper sequence.

(A-WM-5 left side

wheel mandrel has

same components in

opposite sequence)

Cotton, chamois or felt buffs over 4

″ in diameter should not be used with the Bench Lathe.

SPEED

SFPM

1

″ Dia. Buff

Full

7,000 RPM

1,750

Med

4,000 RPM

1,000

2

″ Dia. Buff

Full

7,000 RPM

3,500

Med

4,000 RPM

2,000

SPEED

SFPM

3

″ Dia. Buff

Full

7,000 RPM

5,250

Med

4,000 RPM

3,000

4

″ Dia. Buff

Full

7,000 RPM

7,000

Med

4,000 RPM

4,000

Motor Shaft

set screws

Rubber

Wheel

3. The 7,000 RPM maximum speed will enable

you to get much higher SFPM with smaller

1

″ or 2″ buffs or inside ring buffs, than

slower single or double speed equipment.

4. 3M Scotch-Brite™ Radial Bristle Discs in 2″

and 3

″ diameters require 5,000 or higher

RPM for optimum performance, making

them perfect for use in the lathe.

5. The maximum speed of 7,000 RPM is also

fast enough to permit the use of small

mounted abrasive points, brushes, cutters,

or other accessories in the A-CHA-5 collet

holder, S.B0-516 flexade or A-JCA-2

chuck holder.

For additional information on buffing and

polishing procedure, wheel selection, and

Foredom buffing and polishing compounds,

please refer to the Foredom Buffing and

Polishing Guide (F-1234).

S.B0-516N Flexade

®

Comes with 5/16

″ (8mm) coupling and extra flexible

30

″ long neoprene sheath allows you to use any of

Foredom’s interchangeable handpieces. Must be

attached to the right side of the lathe.

Handpiece not included.

Wheel Mandrels

A-WM-5 Left Hand A-WM-6 Right Hand

Mandrels to hold rubber bonded abrasive wheels,

sanding drums, brushes, and other accessories with

1/4

″ mounting holes and rated for maximum speeds

of 7,000 RPM or higher.

A-CHA-5 Collet Holder

Collet holder on arbor includes

3/32

″, 1/8″, and 1/4″ collets,

pin and wrench. For use with

all 440 series collets in 1/16

″

to 1/4

″ and metric sizes.

Use on right side only.

MADCH-1 Dust Collector Hoods

Heavy gauge sheet metal construction with non-skid

pads on the bottom. 2

1

⁄2″ (64mm) adapter fits most

dust collection system hoses.

Height: 6

1

⁄2″ (165mm)

Width: 4

5

⁄8″ (117mm)

Depth: 8

5

⁄8″ (219mm) deep

HP440 Series collets

P/N

Nominal cap.

HP441

1/16

″

HP442

3/32

″ (2.3mm)

HP443

1/8

″

HP444

5/32

″

HP445

3/16

″

HP447

1/4

″

HP448

3mm

HP449

6mm

A-JCA-2 Chuck Arbor

Adjusts to hold accessories from 0– 5/32

″ (3.9mm).

Comes with chuck key with molded plastic handle.

Use on right side only.

Side of Arbor Hole

Part No. Lathe

Diameter

A-4561

Right hand

3/8

″

A-4562

Left hand

3/8

″

A-4568

Both

1

″

Tapered Spindle Adapters

for Scotch-Brite

™

Radial Bristle Discs

FX Wheel Adapter for 3M

™

FX Polishing Wheels

Attachments shown here fit current models

(2003 and newer) of Foredom’s BL Lathe

which have 5/16

″ diameter straight

motor shafts

Bench Lathe Attachments

These are available from your dealer, the

factory, or you may order them online at

www.foredom.com.

Tapered Spindles

(Supplied)

A-TM5 Left Hand

A-TM6 Right Hand

Precision, true running tapered spindles suitable

for speeds up to 7,000 RPM. Double locking

screws. For use with cotton, felt, and chamois

buffs with shellac-hardened leather, or lead centers.

Also any 3

″ or smaller wheels with arbor holes up to

7/16

″in diameter and rated for 7,000 RPM or higher.

Use A-TM5 on left side (as you face it) and

A-TM6 on right side of bench lathe.