115 volt, 230 volt, Assembly instructions – Foredom Series H Motors User Manual

Page 2: Maintenance, Speed controls

off. Wipe off any excess grease at tip end of

the sheath.

8. Re-attach handpiece.

Never operate the motor with

the outer sheath removed from

the flexible shaft.

Replacement of

Worn Shafts and Sheaths

Shafts and sheaths last longer when they are

not used at sharp angles or loops, since wear

occurs at the points of greatest friction. There is

no way to avoid ultimate wear, and under normal

conditions a flexible shaft machine may require

several replacement shafts and sheaths during

its lifetime.

Installing New Shaft

1. Expose and remove the inner shaft following

steps 1, 2, and 3 at left.

2. Loosen 3/32

″ hex set screw on the flexible

shaft motor coupling on the shaft. Replace with

new shaft.

3. Tighten set screw securely onto the flat of

the motor shaft.

4. Grease shaft prior to putting on the sheath.

Follow lubrication instructions at left.

5. Thread new shaft through sheath

and silencer spring. Tighten sheath nut

(counterclockwise).

6. Hang and run the motor for about 10

minutes before attaching the handpiece to allow

enough time for the grease to warm up, spread

and drain off. Wipe off any excess grease at tip

end of sheath.

7. Re-attach handpiece.

Assembly Instructions

Always make sure your power tool

is unplugged during assembly.

Connecting and Removing square drive

handpieces with locking rings to Series TXH,

SRH, LXH, and H flexible shafts–

1. Pull back

the locking ring

toward the front

end of the

handpiece while

you insert the

tip of the flex

shaft. You may need to rotate the handpiece slightly

until the square shaft tip engages the spindle.

2. Release the

locking ring

when you feel

the shaft

connect to the

handpiece. You

should hear

a click.

3. To remove a

handpiece, pull

back the locking

ring in the same

way and with a

strong action

remove the

shaft and sheath

from the

handpiece.

square drive tip on flex shaft

handpiece

locking ring

pull handpiece locking ring back

to insert shaft tip

handpiece to shaft connection

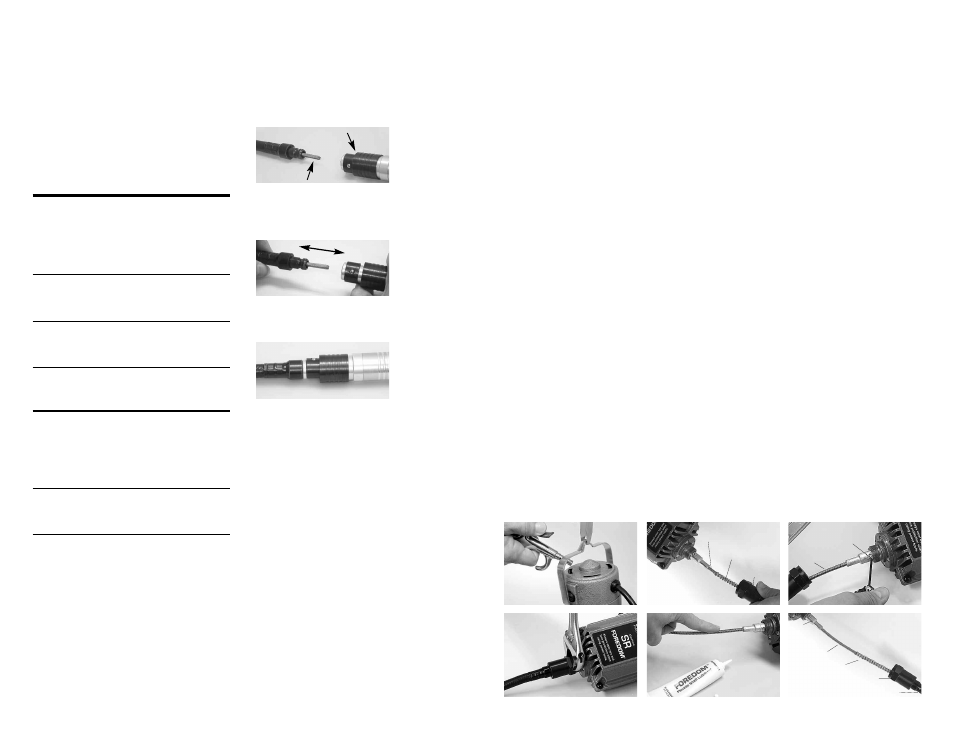

Routine Cleaning and Lubrication

of Flexible Shaft

The shaft should be checked, wiped clean, and

relubricated with grease every 50 hours of use.

With every 200 hours of use, the shaft should be

thoroughly cleaned with solvent and lubricated.

Use Foredom flex shaft grease (MS10006) or

high temperature, quality white lubricating grease.

Exposing the Inner Shaft

1. Remove handpiece

2. Use a 1

″ adjustable wrench to remove the

outer sheath.

Sheath nut has a left hand thread and must be

turned clockwise (right) for removal.

3. The inner shaft is threaded through both a

silencer spring and the outer sheath. Slide the flex-

ible shaft out of the outer sheath to lubricate or

replace the it. The silencer spring tends to stay

inside the sheath – so it may not be visible when

you remove the inner shaft.

4. Apply a very light coating of lubrication to shaft

starting at the top and working downward to about a

few inches from the end. Apply grease with your fin-

ger tip or small brush. Don’t overdo, apply a very

light film of grease. Once the machine is running,

the shaft itself will spread the grease. If too much

grease is applied, the excess will work its way into

the handpiece and eventually seep out between the

handpiece and sheath. For this reason, apply a bit

less near the handpiece end of the shaft.

5. Replace both spring and sheath and tighten

sheath nut (counterclockwise).

6. Wipe the exterior of sheath with a cloth.

7. Hang and run the motor for about 10 minutes

before attaching the handpiece to allow enough

time for the grease to warm up, spread and drain

2

3

hexagonal

set screw

motor

shaft

shaft

silencer spring

sheath

motor

coupling

shaft

silencer spring

motor connector

sheath

Maintenance

Always make sure your power tool

is unplugged when conducting

maintenance procedures!

Motor

– No lubrication of the motor is required,

however, it is important to keep the motor clean.

Remove any build up of dirt, chips, dust, or other

debris that may have entered through the slots

in the motor housing using a brush or by blowing

air through the motor (shown at right). It is also

important to check for and replace worn motor

brushes periodically – see page 4 and read

your manual for instructions.

Square Drive Handpieces

– No lubrication

is required. Remove any build up of dirt, chips,

dust or other debris from collet seat or chuck.

Read the handpiece instructions for

additional information.

Speed Controls

Motors featured in this insert must be used in

combination with the speed controls shown

below. Damage to the motor will result if used

with the wrong control. Do Not plug the motor

directly into an AC electrical wall outlet.

Plastic Metal

Table

Top

Foot

Foot

Dial

Motor

Control

Control

Control

115 Volt

M.TXH

and

C.TXR-1

C.SXR-1

C.EMX-1

M.TXBH

M.LXH

and

C.TXR-1

C.SXR-1

C.EMX-1

M.LXBH

M.SRH

and

C.FCT-1

C.SCT-1

C.EM-1

M.SRBH

M.H

and

C.FCH-1

C.SCH-1

C.EMH-1

M.HB

230 Volt

M.LXH

and

C.TXR-2

C.SXR-2

C.EMX-2

M.LXBH

M.SRH

and

C.FCH-2

C.SCH-2

C.EMH-2

M.SRBH

M.H

and

C.FCH-2

C.SCH-2

C.EMH-2

M.HB

Remove

outer

sheath

keep the

motor clean

apply grease with

your finger tip