Caution – IAI America IX-NNC3515 User Manual

Page 34

28

6. Inspection/Maintenance

6.1.1

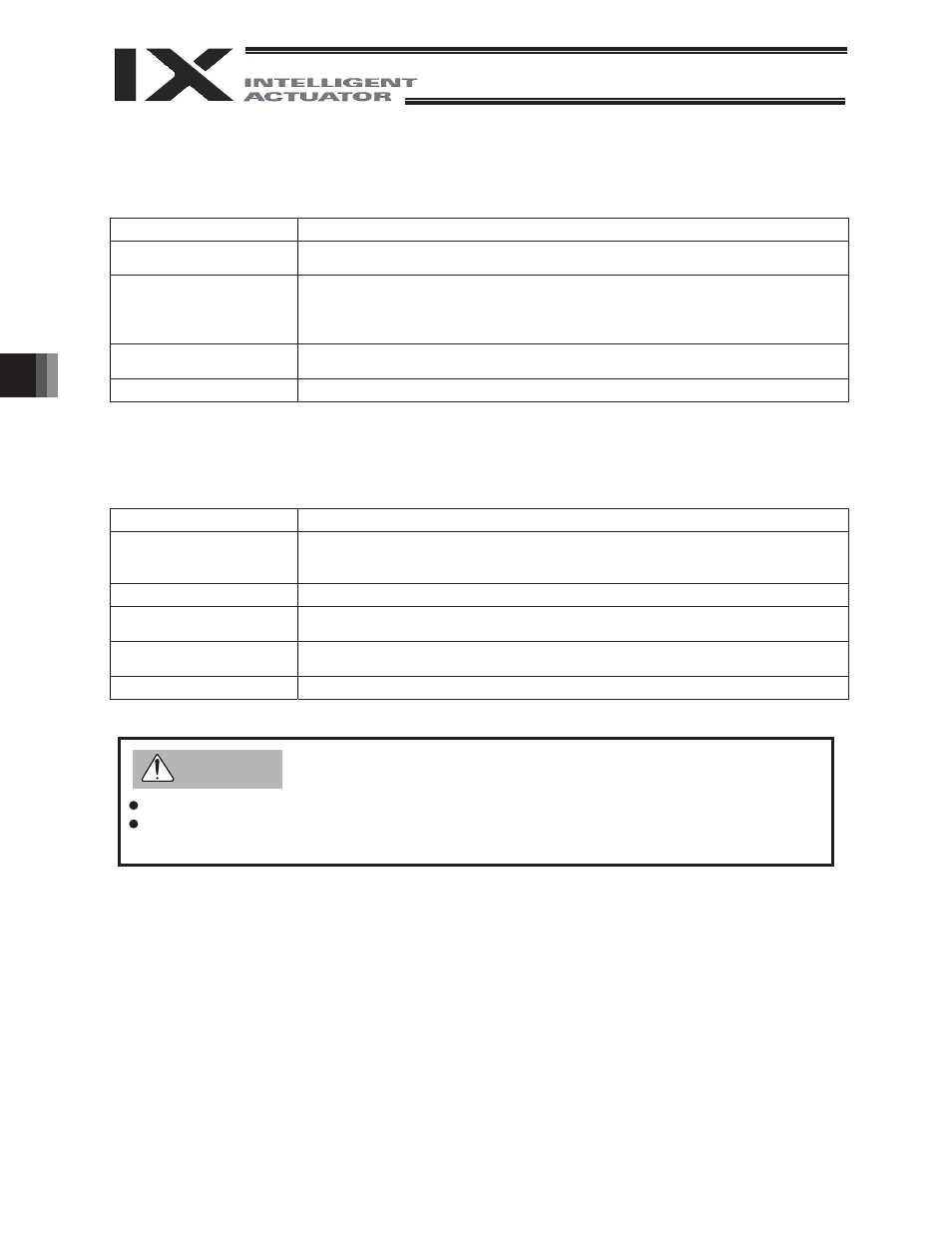

Daily Inspection

Check the following items daily before and after operating the robot.

Observe the precautions for work near the robot and for inspection/maintenance/adjustment operations

when carrying out each check.

Check location

Description

Safety cage

Correct the deformation or positional shift of the cage.

Confirm that the interlock mechanism is operating properly.

Robot

Check the robot mounting bolts for looseness.

Check the exterior for abnormality, loose covers, flaws, dents, etc.

(If the robot has flaws or other abnormalities, please contact IAI.)

Check for abnormal move, vibration or noise.

Cables

Check the cables for flaws.

Check the cable mounting parts for looseness.

Emergency-stop switch

Confirm that the emergency-stop switch functions properly.

6.1.2

Six-Month Inspection

Check the following items on the robot every six months.

Observe the precautions for work near the robot and for inspection/maintenance/adjustment operations

when carrying out each check.

Check location

Description

Robot

Check the arm mounting sections for looseness.

(If any of the arm mounting sections is loose, tighten the fastening parts

securely.)

Ball-screw spline

Add grease. (AFE Grease by THK or equivalent)

Timing belts of axes 3

and 4

• Check the belt tension for axes 3 and 4.

• Check the belts for flaws, cracks, wear, etc.

Reduction gear unit of

axis 4

Add grease. (Multemp AC-D by Kyodo Yushi or equivalent)

Connectors

Check the connectors for looseness.

If the robot has flaws or other abnormalities, please contact IAI.

Caution

In case the grease got into your eye, immediately go to see the doctor to get an appropriate care.

After finishing the grease supply work, wash your hands carefully with water and soap to rinse the

grease off.