Securitron EPT_EPTL User Manual

Page 2

PN# 500-14250

Page 2

Rev. , 04/11

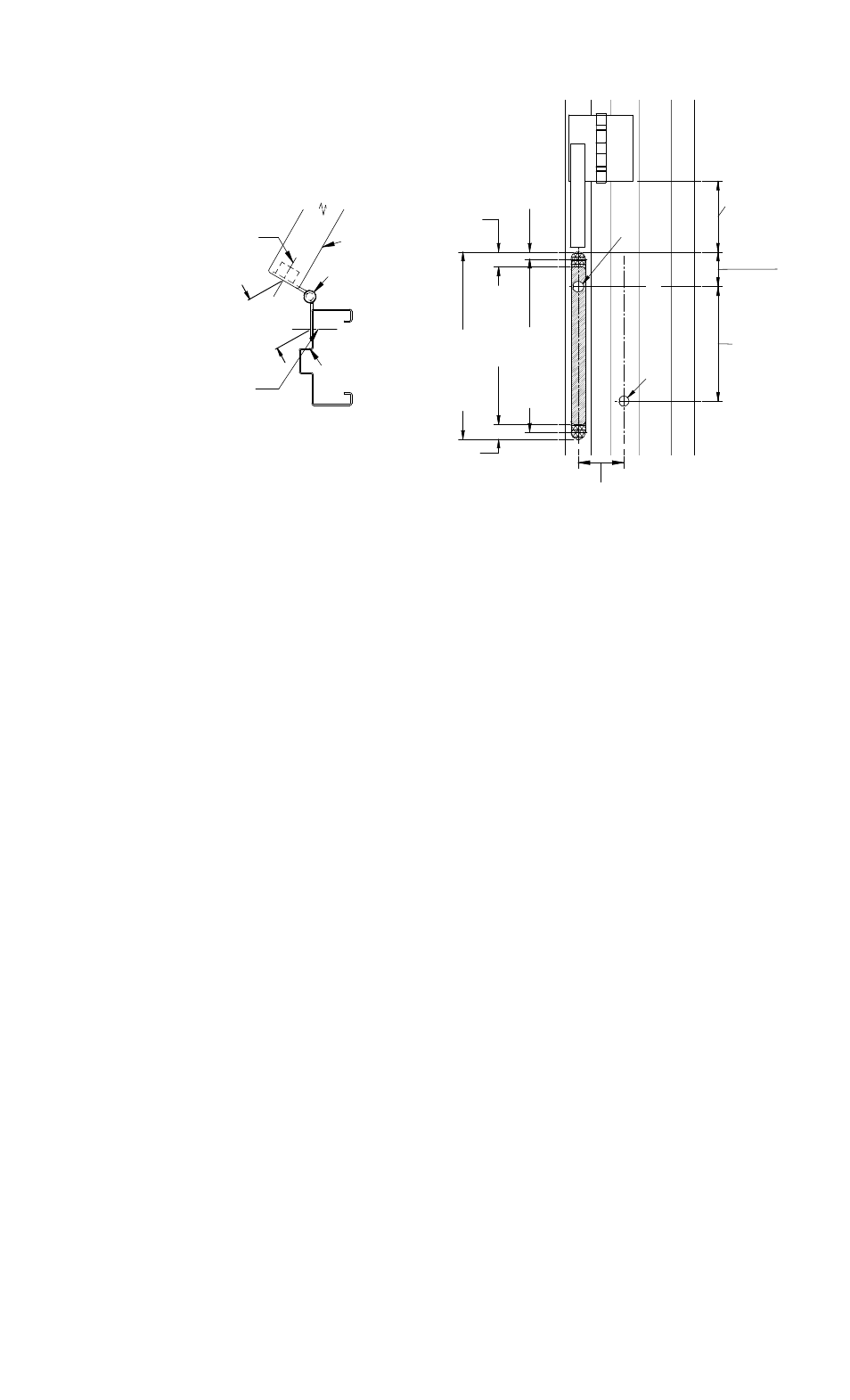

SWING GAP DISTANCE

MEASUREMENT:

EPT ~ LESS THAN 2.5" [63.5mm]

EPTL ~ GREATER THAN 2.5" [63.5mm]

(DOOR)

(HINGE)

(DOOR FRAME)

CENTERLINE REFERENCE

3/4" [19,0mm] DIAMETER

HOLE IN DOOR EDGE AND

SLOT FOR MOUNTING LEAD COVER

CENTERLINE REFERENCE

11/16" [17,5mm] DIAMETER

HOLE IN DOOR FRAME FOR

MOUNTING FLEXIBLE CABLE

7.

8

0

E

P

T

:

[1

9

8

,1

]

EP

T

L

: 1

6

.3

0

[4

1

4

,0

]

3/

4"

[

1

9

,0]

D

iam

et

e

r

1

1

/1

6"

[

1

7

,5]

D

ia

m

et

er

6

.0

0

[1

5

2

,4

] o

r

Re

c

o

m

m

e

n

d

e

d

(

M

in

imu

m

)

C

e

n

ter

Be

tw

een

B

u

tt

H

ing

es

These Two (2) Centerlines

Must Align When Door Is Closed

.495

[12,7]

1.01

[25,7]

1

0

.7

5

[2

73,

1]

1

9

.4

0 [

4

92

,8

]

1.01

[25,7]

1

2

.7

7

[32

4,

4

]

2

1

.4

3

[5

4

4

,3

]

1

1

.7

7

[29

9,

0

]

20

.4

3 [

5

18

,9

]

2.

45

[62,

2]

C

e

n

ter

li

n

e of

D

o

or

Ce

nt

e

rl

ine

of

Do

or

Figure

1

Figure

2

Wood Doors and Frames

Using a router, cut the main recess slot into the edge of the door .700” [17,8mm] deep as

explained in Figure 2 and Figure 3. Reset the router depth to .075” [1,9mm] and route the two

(2) recess flange areas for the flush mount tabs. Place the lead cover into position and mark the

location of the cable exit oblong hole and the mounting hole locations. Remove the Lead Cover

and drill the (2) two holes using a 1/8” [3,2mm] diameter drill approximately 1/2” [12,7mm]

deep. Drill the 3/4” [19,0mm] diameter hole into the door edge. Pass cable from the exit device

through the hole in the door edge. Pass the cable through the oblong hole in the Lead Cover.

Properly attach the two (2) electrical connectors at the door location. Mount the Lead Cover into

place using the two (2) #6 x 5/8” Flathead Type-A Screws provided. Locate and mark the

mounting holes for the Flexible Shield onto the door frame. Drill the 11/16” [17,5mm] diameter

hole into the door frame. Drill (2) two holes using a 1/8” [3,2mm] diameter drill approximately

1/2” [12,7mm] deep for mounting of the Flexible Shield. Pass the cable through the Flexible

Shield and apply Bezel Plate if not preassembled. Properly attach the two (2) electrical

connectors at the frame location and pass into the hole of the door frame. Mount the Flexible

Shield onto the Lead Cover using the two (2) 8-32 x 3/16” Screws and #8 Split Helical Washers

provided. Align the cable and the other end of the Flexible Shield onto the door frame and

secure using the two (2) remaining #6 x 5/8” Flathead Type-A screws provided as shown in

Figure 4.

Note: The frame side of the Flexible Shield requires the Bezel Plate

for concealing the oversize hole when mounted to the frame.

Metal Doors and Frames:

Metal doors must also have a flush surface mount installation. The door/frame manufacturer

may prepare a pre-fabricated tab for internal mounting capabilities or use the Flush Tab Brackets

provided. The cut out for the Lead Cover may be cut with a radius or square cornered as noted in

Figure 3 and on the Template provided. If field retrofit installation is being performed, route the

complete perimeter of the bracket and tab area and install the EPT/EPTL using the Flush Tab

Brackets provided. When mounting the Lead Cover, drill the mounting holes 1/8” [3,2mm] and

use the 6-32 x 3/8” Type “F” Self Tapping Screws provided. Follow the Template provided for

placement of the screw holes for the Flush Tab Brackets. Also when mounting the Flexible Shield

to the metal door frame, drill the same holes at 1/8” [3,2mm] and use the two (2) remaining 6-

32 x 3/8” Type “F” Self Tapping Screws.

Note:

Applications

containing combinations of doors or frames made of wood

or metal; follow the proper procedures related to the device as necessary.