Securitron PB5 User Manual

Page 2

PN# 500-23150

Page 2

Rev. C, 05/11

4. WIRING

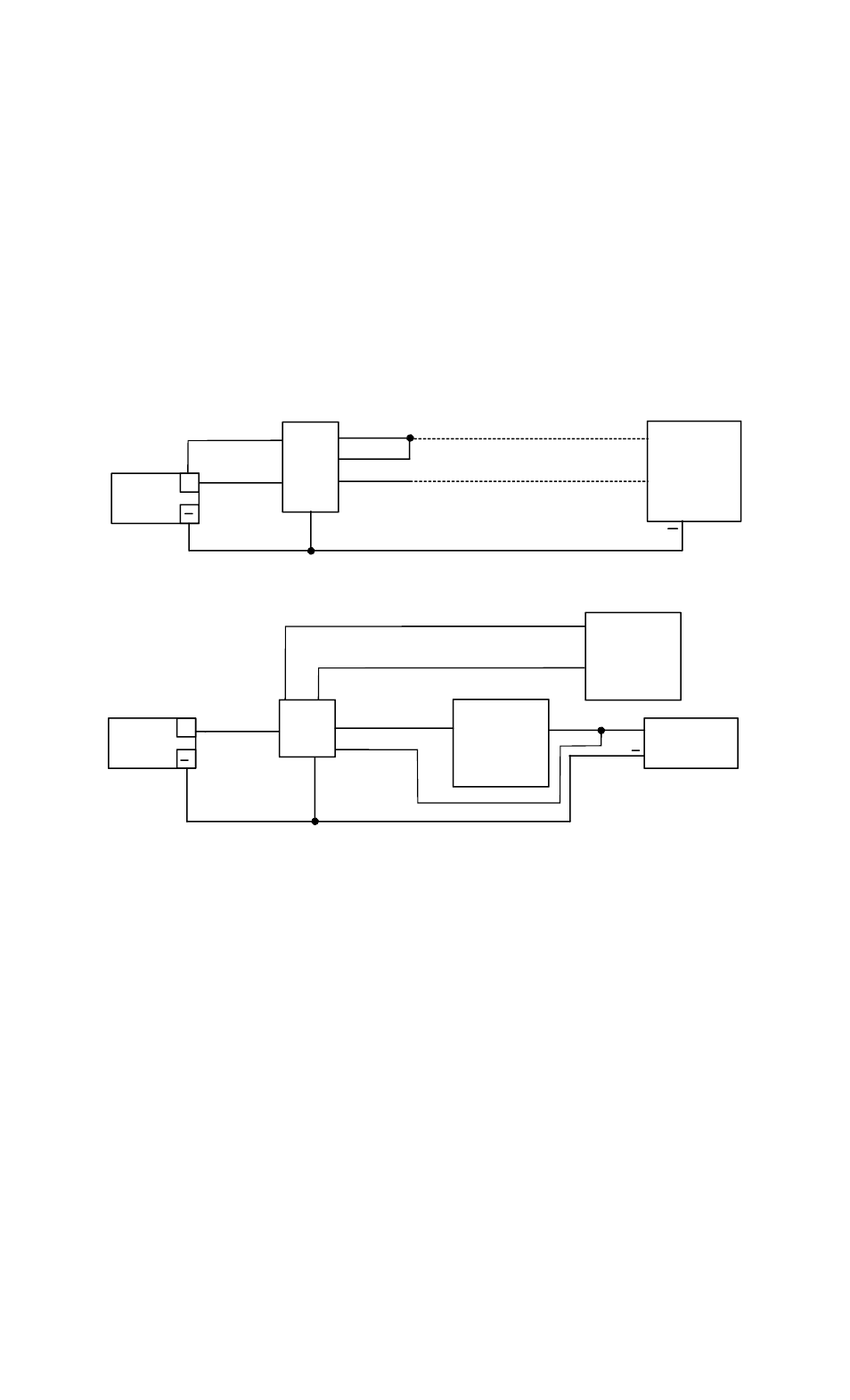

The drawings below show two common applications. The first shows momentary release of a fail

safe or fail secure electric lock. The PB5 indicator is connected so that the switch LED is

normally on (which helps guide a person to the push button). When the button is pressed,

releasing the lock, the switch LED turns off. The second drawing shows interface of the PB5 with

an access control system such that a fail safe lock (generally a magnetic lock) is released for the

amount of time programmed into the system in safe, double break fashion. This application

uses both poles of the PB5. The NC contacts of the PB5 are connected in series with the NC

contacts of the access control system’s lock control relay and the NO contacts of the PB5E

connect to the REX input terminals of the access control system such that when the button is

pressed, the access control system will operate its relay thereby releasing the lock and allowing

egress. But if the access control system experiences an electronic failure, the PB5E contacts will

still directly release the fail safe lock for as long as the button is held pressed.

Note: for special applications, unwired contacts NO1 and NC2 can be connected for full DPDT

switch operation. You will see the unwired spade terminals on each contact block.

POWER

SUPPLY

+

D.C. LOCK

ELECTRIC

PB5

+

WHITE/RED

BLUE

RED

BLACK

+

GREEN

IF FAIL SAFE

IF FAIL SECURE

MOMENTARY RELEASE OF FAIL SAFE OR FAIL SECURE ELECTRIC LOCK

WHITE/BLUE

POWER

SUPPLY

+

COM

D.C. LOCK

FAIL SAFE

NC

PB5

+

ACCESS

SYSTEM

RELAY

ACCESS

SYSTEM

REX INPUT

TIMED DOUBLE BREAK: FAIL SAFE LOCK USED WITH ACCESS SYSTEM

WHITE/RED

RED

W

H

IT

E/

BL

U

E

BL

U

E

GREEN

BLACK

4. ALTERNATE LENS CHANGING

The pushbutton is factory shipped with the red lens set installed and two lens/insert options.

Changing to the other lens sets is simple.

1) Grasp keyplate and turn over. From the back rotate the white contact block of the switch

counter-clockwise to the 11 o’clock position and pull straight back to remove the contact

block.

2) With a slender smooth ended object such as a marker pen, slide it inside the switch body.

With the object inserted in the switch up against the lens, place the object on a smooth

surface with the keyplate on top, and tap the keyplate up and down on the object to pop

the lens off. Remove the lens and insert.

3) Turn the keyplate over and place the new insert onto front of switch, confirm that the text

on the insert is correct reading to the keyplate and place the matching colour lens on top of

the insert and compress around all edges of the lens until it snaps in place. Depress lens

several more times to ensure smooth operation and that the lens is not binding.

4) With the terminals upward insert the contact block back into the back of the switch at the

11 o’clock position and rotate clockwise until it stops straight up and down.