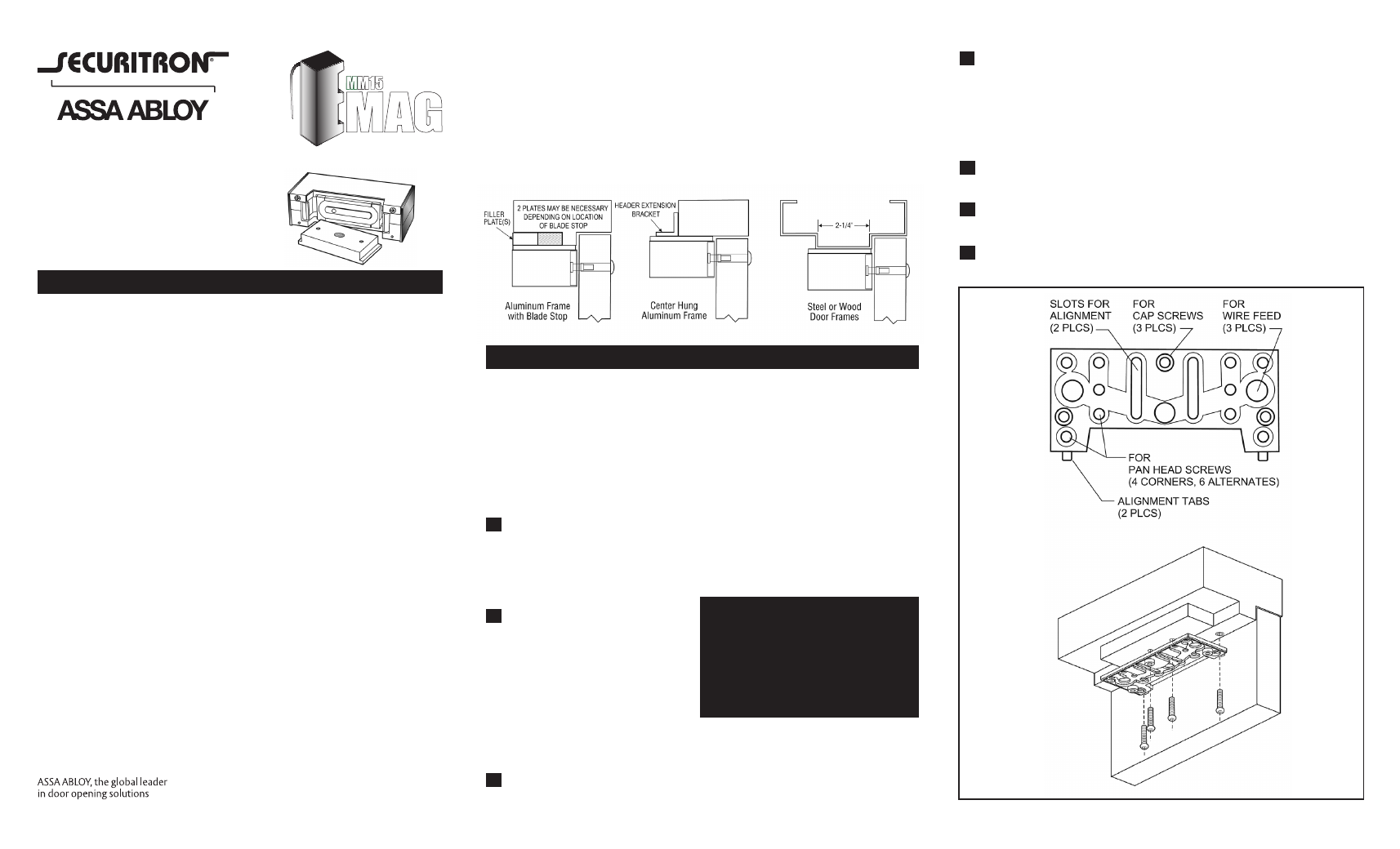

Installation instructions, Frame preparation, Mm15 maglock mounting basics – Securitron MM15 User Manual

Page 2

4

In each mounting location, drill a 3/8” hole in the header and

install Blind Nuts, using the supplied hex wrench. Refer to

Blind Nut installation instructions in the mounting hardware

kit.

Note: In reinforced steel frames, it is permissible to drill

5

If not using conduit, drill one 9/16” (or 3/8” minimum) wire feed

hole in the door frame.

6

Replace the mounting plate and filler plate, then secure with pan

head screws using thread lock.

6

Additional screws may be installed for added stability and strength

in any of the alternate holes.

Frame Preparation

Frames need to be marked for drilling using the mounting plate as a

template. Doors need to be marked for drilling using the plastic armature

template. All measurements should be made with the door in the fully

closed position.

To ensure the proper location of the maglock and armature for successful

mounting, adjust the MM15 to clear other hardware or door and frame

features that would interfere with the installation.

1

Place the filler plate on the

mounting plate. The filler

plate should be aligned with

the back edge and sides of

the mounting plate.

2

With the door fully closed,

locate the mounting plate and

the filler plate to the header

with the alignment tabs resting

on the face of the door. Using

the predrilled holes in the center

of the filler plate and two of the

furthest forward corner holes,

mark four holes for mounting

the two plates to the header.

3

If not using conduit, mark one

of the wire feed hole locations.

Installation shown with use

of filler plate. Mounting will

differ for other applications.

WARNING:

This device is capable of holding

4000 lbs. It is the responsibility of

the installer to provide adequate

strength to prevent screw pullout

or collapse of the frame or header.

MM15 Maglock Mounting Basics

Maglocks are used in a wide variety of applications; therefore it is

important to inspect the door frame area for proper placement of the

device. For optimum performance, the mounting surface should be

strong enough so that the full holding strength of the MM15 is utilized.

Different door frame configurations require specific fastening methods.

A filler plate or header extension bracket is often needed to properly

support the MM15. Steel blind nuts are the preferred method of

mounting in steel and aluminum frame construction, although drilling

and tapping is acceptable in reinforced hollow metal frames. A

minimum of four blind nuts are required to provide adequate strength.

For standard applications, the electro-magnet should be mounted

firmly to the underside of the header in the corner farthest away

from the hinges. The armature mounts to the face of the door with

special hardware, which allows for proper floating action. This action

is very important in assuring total mating of the armature with the

face of the electro-magnet.

Handle all electro-magnetic locks and armature plates carefully. Any

damage to the mating surfaces may significantly reduce holding

efficiency.

Site Survey

When used with frames with an integral jamb or with narrow frames

that do not fully support the MM15, use the appropriate filler plate or

header extension bracket to adequately support the base of the MM15.

A Z-Bracket is required when installing the MM15 on in-swinging

door. The Z-Bracket installation instructions are included in the MM15

Z-Bracket Kit.

This product must be installed

according to all applicable building

and life safety codes.

Installation Instructions

MM15-01 Rev. C

Page 1

Aluminum Door Systems:

Door frames with blade-type/narrow stops will require a filler plate. The

height of the stop is needed when ordering filler plates. Narrow frame

sections and centerhung doors require an angle bracket to support the

MM15.

Steel/Wood Door Frames:

For adequate support, a door with stops less than 2-1/4” wide should

be fitted with a filler plate.