Robot waterbase applicator - maintenenace, Fluid system – Ransburg Evolver Water Applicator 78863-90, 78863-60 User Manual

Page 39

35

Robot Waterbase Applicator - Maintenenace

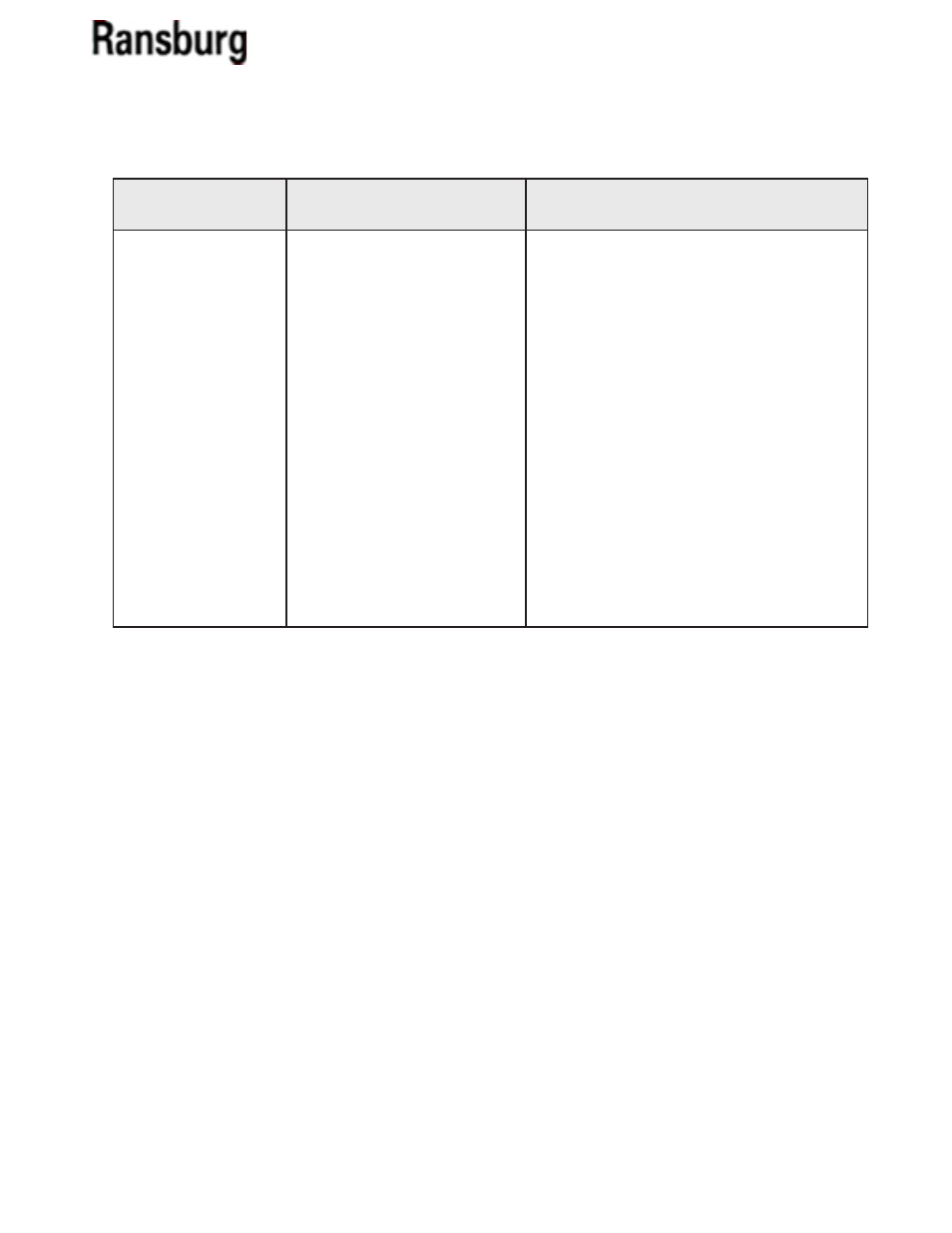

General Problem

Possible Causes

Corrective Action

Excessive Current or Loss

of High Voltage

1. Fluid tube leak inside fluid

isolation tube, charged paint

grounds out at robot arm

manifold.

2. Tubing or conductive

sheath nicked or cut.

3. Internal end of fluid tube not

seated properly into valve

manifold assembly.

4. Contaminated dump line.

5. Exterior of gun contaminat-

1. Replace any worn or damaged o-rings on

EMFD-29-1 barbed fittings.

2. Replace any worn or damaged o-rings on fluid

isolation tube.

3. Fluid tube too short. Check for correct length

of fluid tube. Refer to Figure 21, Robot

Manifold Assembly.

1. Replace tubing or conductive sheath.

1. Ensure fluid tube is seated tightly into valve

manifold assembly.

1. Clean or replace

2. Clean with non-polar solvent

Fluid System

Fluid and Isolation Tube

Note: To check for fluid leaks, it is easiest to first remove the gun from the test station and remove the shroud

from the gun. The aluminum flange can be reattached to the gun manifold plate by using the three stainless

steel screws. Then the gun can be remounted to the test station. Leak detector may be used at all appropriate

sources. Be certain to wipe off all residual solution using a non-conductive solvent such as Naphtha.

AA-03-01.1